Optical fiber ring packaging structure applicable to medium/high-precision optical fiber inertia unit

A packaging structure, fiber ring technology, applied in installation, optics, measurement devices, etc., can solve the problems of uneven temperature distribution of the fiber ring, fiber optic gyro bias error, fiber optic gyro output error, etc., to achieve good air tightness, easy to use. The effect of machining and assembly, good vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

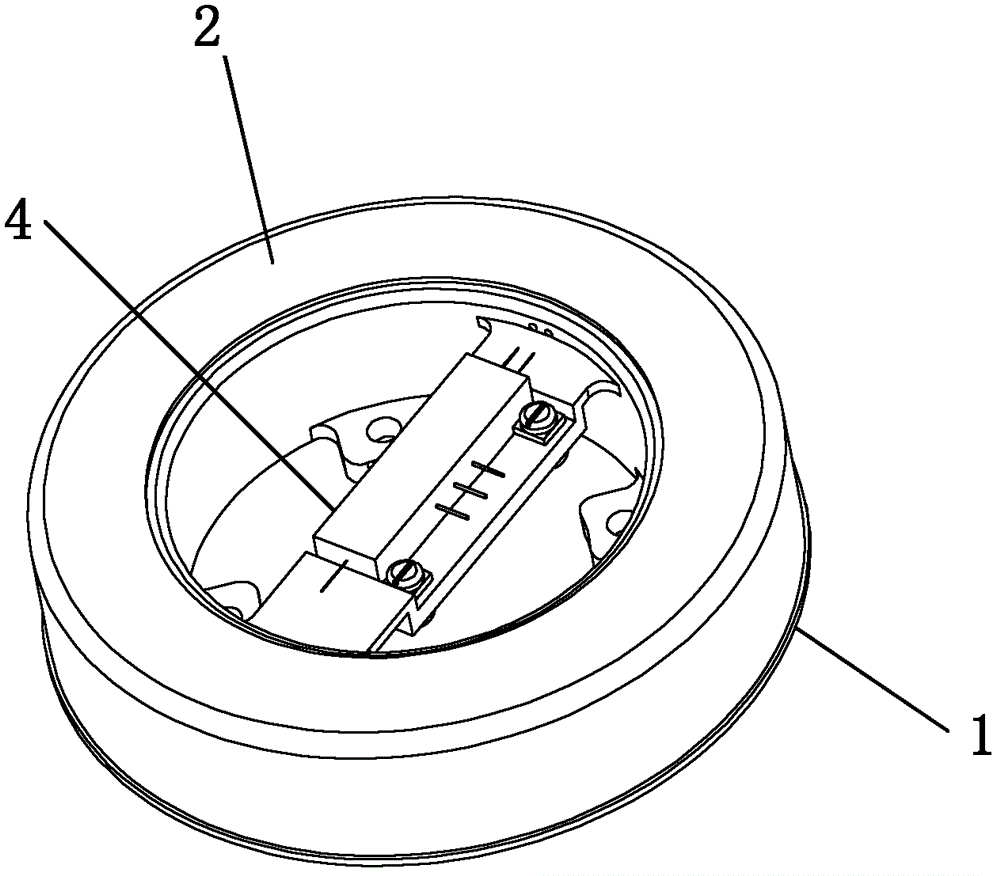

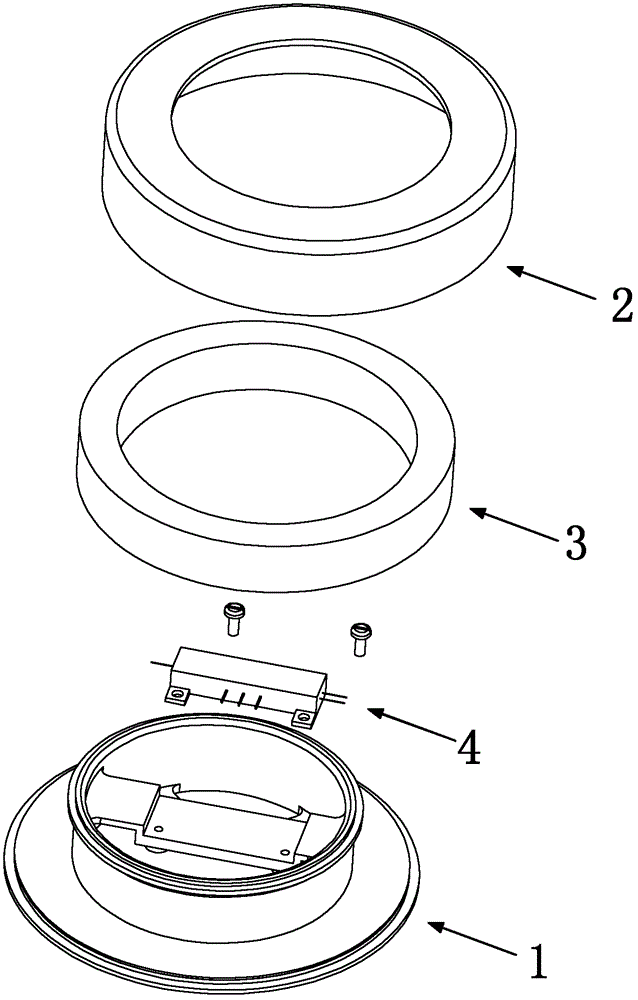

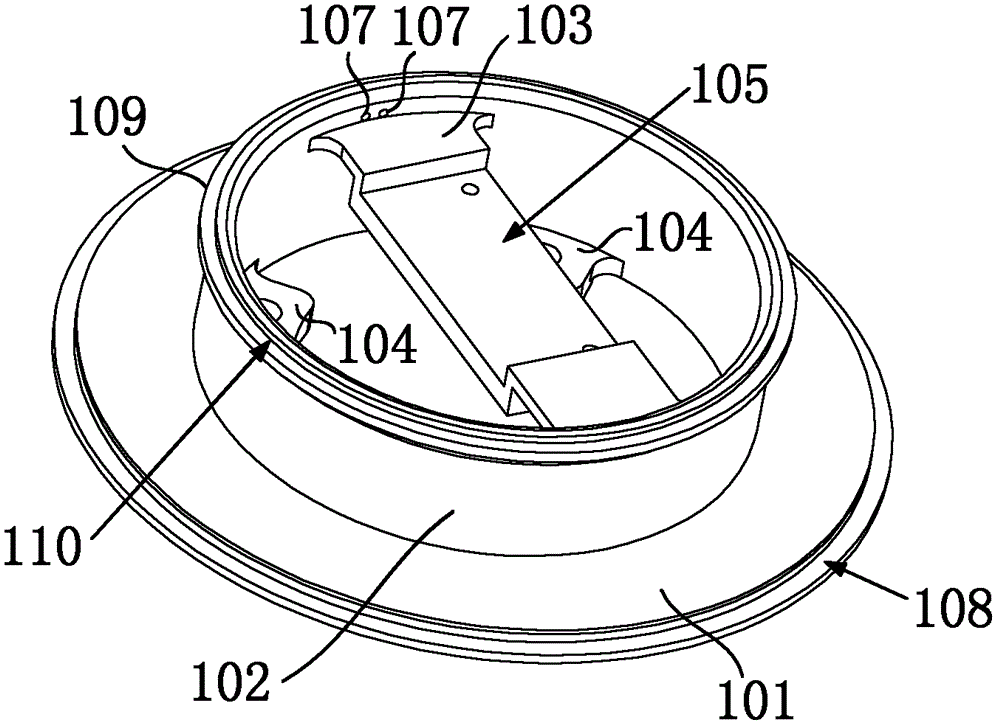

[0025] The optical fiber ring packaging structure of the present invention includes a support body 1 and a cover 2, such as figure 1 , figure 2 shown. Wherein, the support body 1 is an integral structure composed of an annular chassis 101, a sleeve 102, a Y waveguide installation beam 103 and an installation surface 104, as shown in image 3 As shown, the inner circumference of the annular chassis 101 is connected to the bottom end of the sleeve 102 in the circumferential direction, and the annular chassis 101 and the sleeve 102 are used to place and position the optical fiber ring 3 respectively. The Y-waveguide installation crossbeam 103 is arranged on the inner side wall of the sleeve 102, and the middle part of the upper surface of the Y-waveguide installation crossbeam 103 is concaved to form a Y-waveguide installation groove 105, and the Y-waveguide 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com