Lithium ion battery and electrolyte solution thereof

An electrolyte and lithium-ion technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems that cannot really improve the high-temperature storage performance of lithium-ion batteries, and achieve improved high-temperature storage performance, positive electrode protection, and small thickness expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

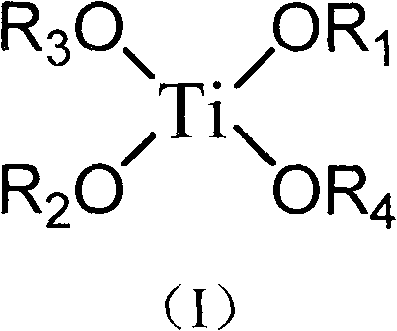

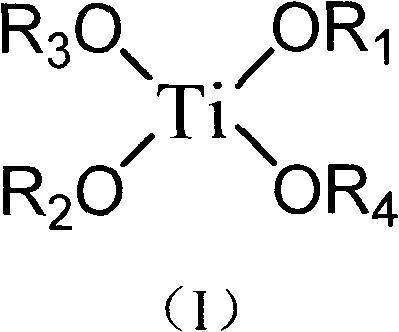

[0028] Electrolyte preparation: Mix ethylene carbonate (EC), propylene carbonate (PC), ethyl methyl carbonate (EMC) and vinylene carbonate (VC) in a ratio of 35:30:30:5 (mass ratio) , then mix uniformly with 99 mass parts of this mixed solvent and 1 mass part of tetrabutyl titanate, add lithium hexafluorophosphate (LiPF 6 ), dubbed LiPF 6 Electrolyte with a concentration of 1mol / L.

[0029] The production of the positive electrode sheet: the positive active material lithium cobaltate (LiCoO 2 ), the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) in the N-methylpyrrolidone solvent system in a weight ratio of 96:2:2 are fully stirred and mixed uniformly, coated on the Al foil, and dried , cold pressing, and cutting into pieces to obtain positive pole pieces.

[0030] The production of the negative electrode sheet: the negative active material graphite, the conductive agent acetylene black, the binder styrene-butadiene rubber (SBR), and the thi...

Embodiment 2

[0034] Different from Example 1 is the preparation of electrolyte: diethyl carbonate (DEC), propylene carbonate (PC), dimethyl carbonate (DMC) and gamma-butyrolactone according to 40: 25: 30: 5 ( (mass ratio) ratio mixes, then with this mixed solvent of 90 mass parts and the tetraisopropyl titanate of 10 mass parts mix homogeneously, add lithium tetrafluoroborate (LiBF 4 ), made into an electrolyte with a LiBF4 concentration of 0.8mol / L.

[0035] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0037] The difference from Example 1 is the preparation of the electrolyte: methyl propyl carbonate (PMC), dipropyl carbonate (DPC), propylene carbonate (PC) and fluoroethylene carbonate (FEC) according to 40:25:30 : 5 (mass ratio) ratio mixing, then mix with this mixed solvent of 95 mass parts and the tetraethyl titanate of 5 mass parts, add lithium tetrafluoroborate (LiBF 4 ), dubbed LiBF 4 Electrolyte with a concentration of 1.2mol / L.

[0038] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com