High-quenching-rate material impact synthesis and recovery device

A recovery device and speed technology, applied in the field of material impact synthesis and recovery devices, can solve the problems of impact pressure reduction, radial rebound, and increased difficulty of recovery, so as to reduce the influence of metal impurities, improve radial tensile strength, The effect of preventing the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

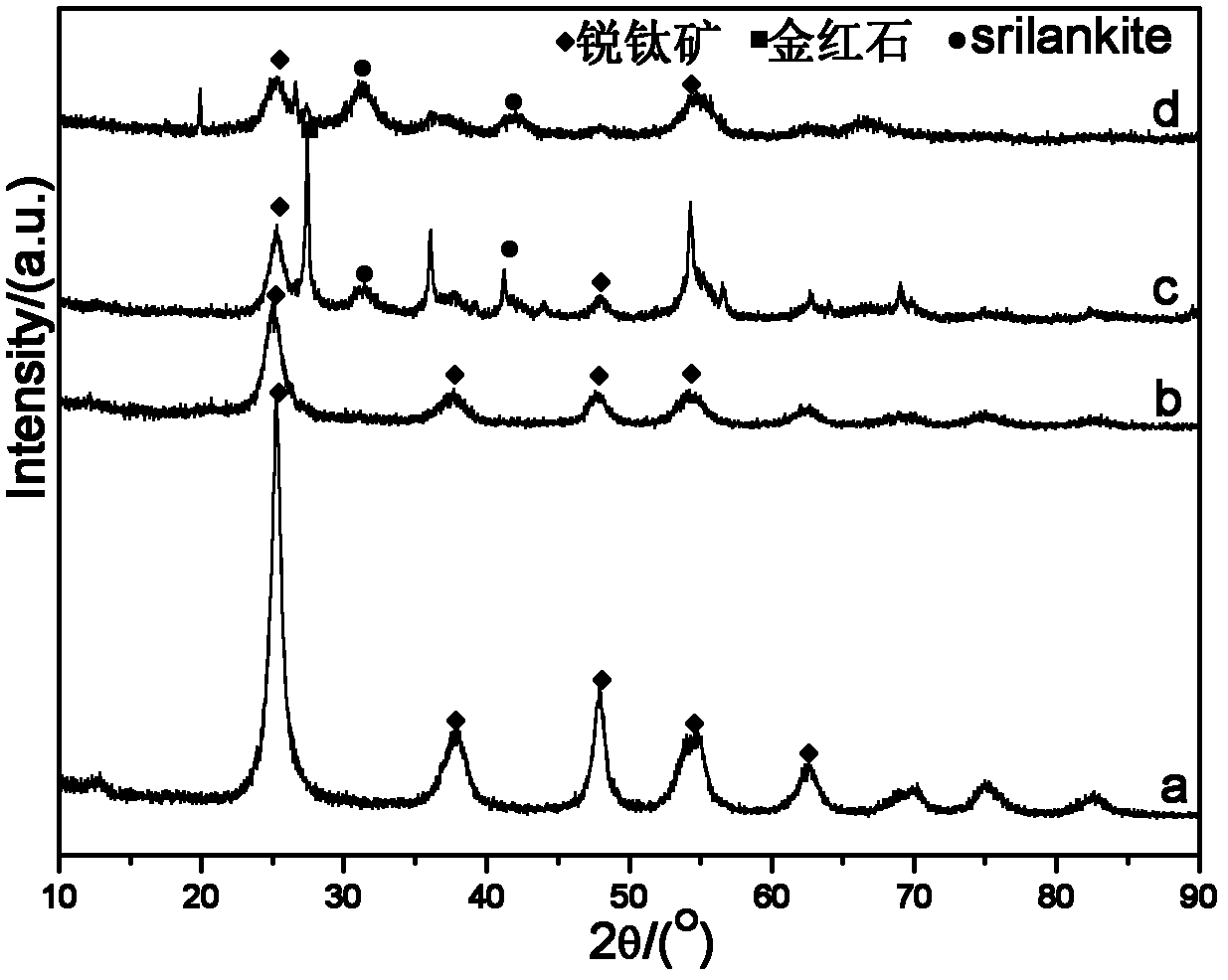

Examples

Embodiment Construction

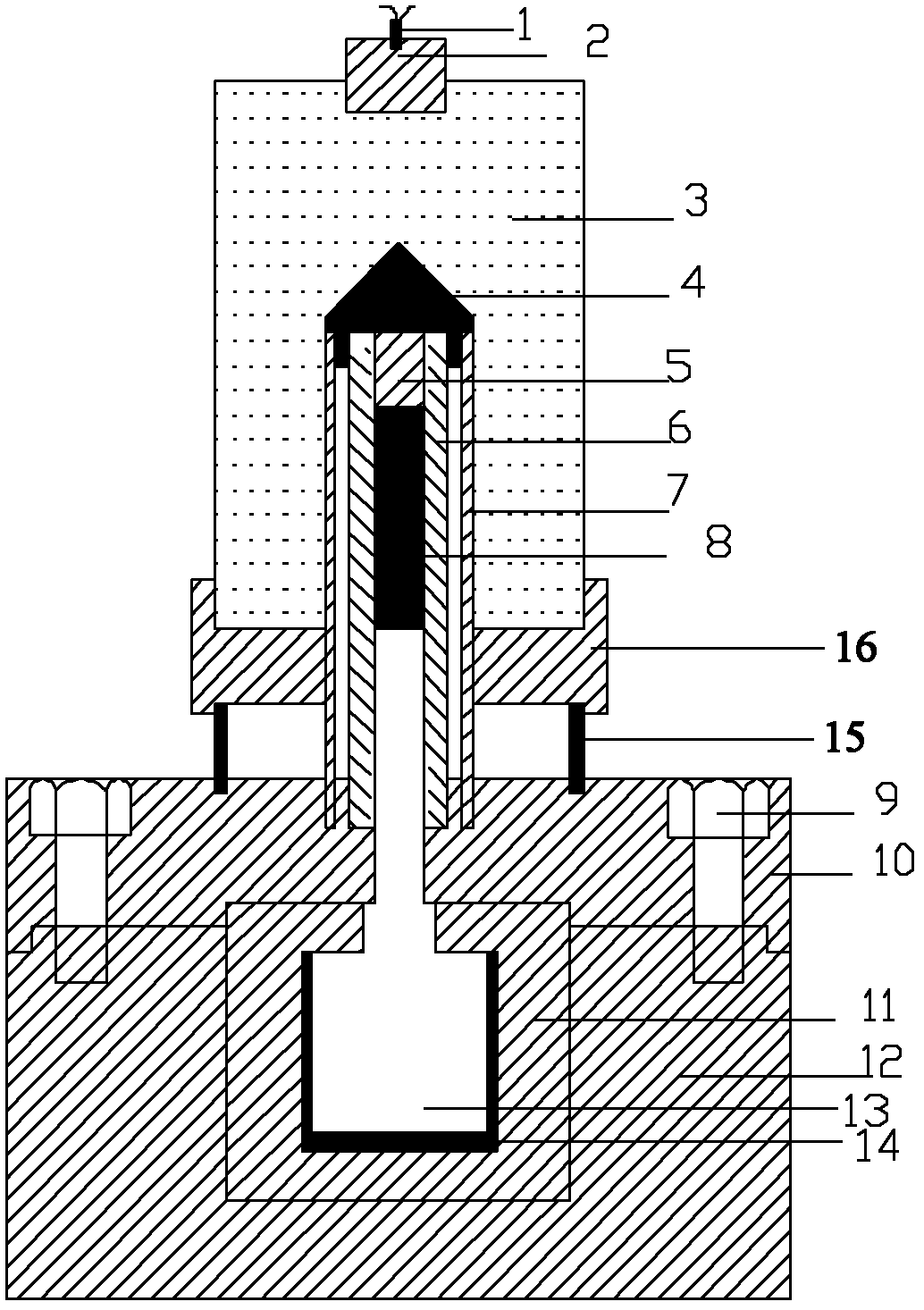

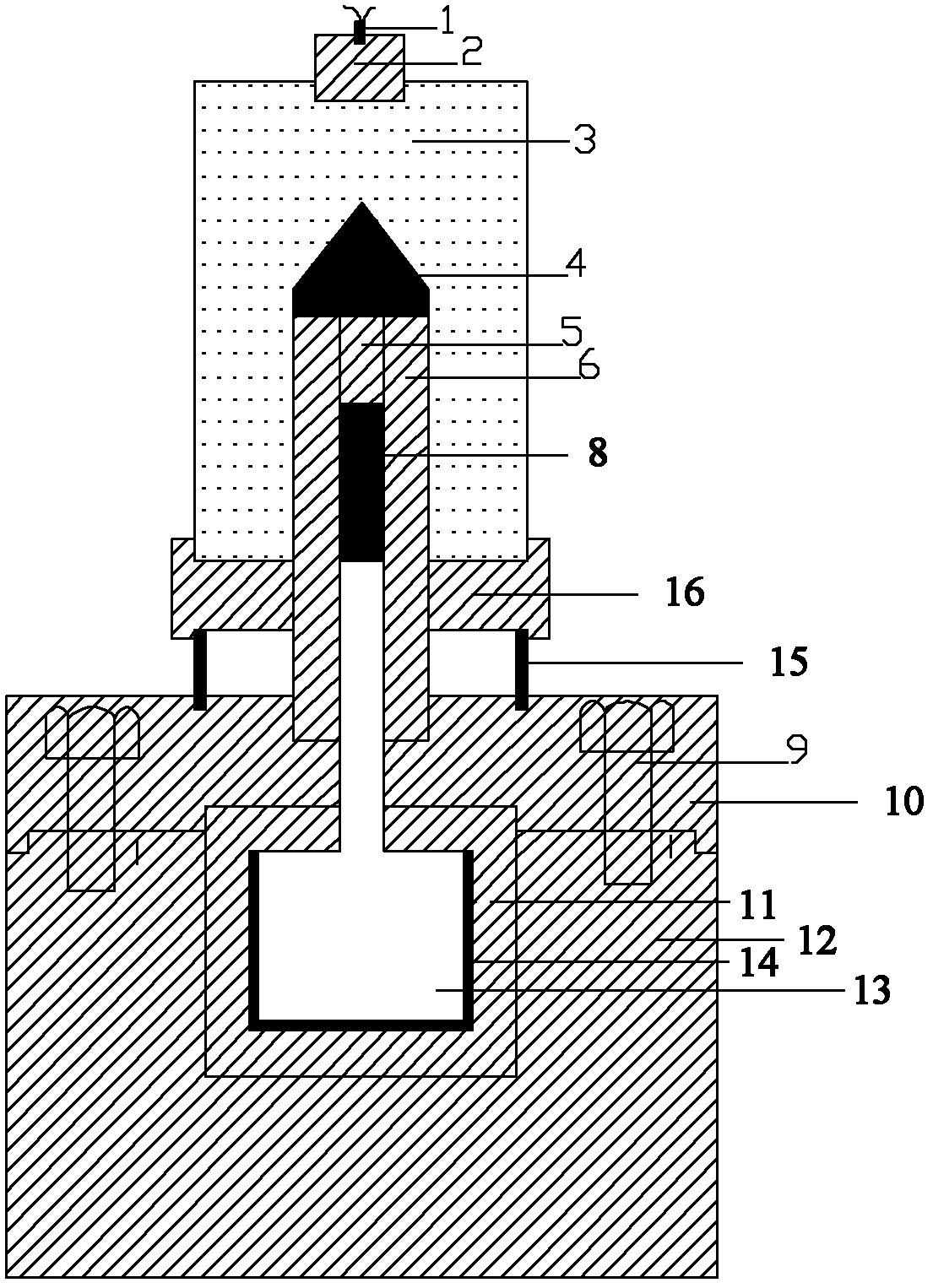

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] The invention provides a material impact synthesis and recovery device with a high quenching rate. The basic idea is that on the original cylindrical impact loading device, the lower end of the sample tube is opened, and a cooling medium (liquid nitrogen, water, dry ice, etc.) is placed in the lower part of the device. etc.), rush the sample treated by the shock wave into the sample box with the cooling medium in the lower part for cooling, increase the quenching rate, ensure the reliable recovery of the sample, and complete the shock treatment and rapid cooling process in the same experimental device , the process is simple, can ensure the safe and reliable implementation of subsequent processes, and is suitable for the preparation of metastable phase and mesophase materials.

[0031] figure 1 It is a schematic diagram of a high quenching rate mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com