Treatment method for whitening of inner surface of food grade glass fiber reinforced plastic container

A processing method and technology of glass fiber reinforced plastic, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of inability to completely eliminate the phenomenon of whitening, whitening of joint reinforcement, and difficulty in surface cleaning, so as to eliminate the problem of whitening. , Easy to exclude, to ensure the effect of inner surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The concrete implementation method of the present invention is as follows:

[0015] (1) The body 1 of the glass fiber reinforced plastic container is produced according to the conventional winding process, and the tank top 2 and the tank bottom 3 are produced by the conventional hand lay-up process; the cylinder body 1, the tank top 2, and the tank bottom 3 are conventionally spliced;

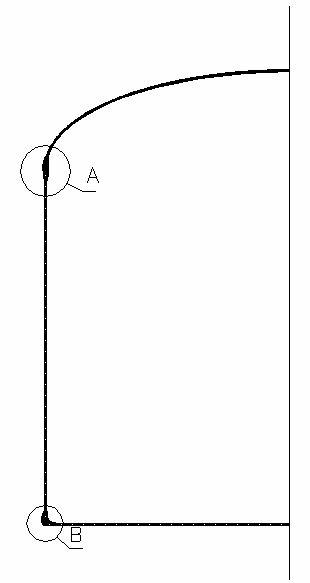

[0016] (2) Grind and clean the strengthened areas of the butt joints on the inner and outer surfaces of the tank body 1, tank top 2, and tank bottom 3 as usual; The seam strengthening area is B, such as figure 1 shown;

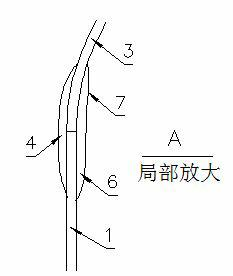

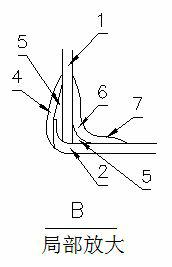

[0017] (3) if Figure 2-3 Shown: Putty 5 and paste fiber reinforced FRP 4 are filled in the reinforced area of the external butt joint as usual;

[0018] (4) Fill putty 5 and paste reinforced glass fiber reinforced plastics in the strengthened area of the butt joints on the inner surface as usual;

[0019] (5) A layer of chemical fiber release cloth 7 is uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com