Colored UV (ultraviolet) coating

A coating and colored technology, applied in the direction of coating, can solve the problem that the color and performance cannot be achieved at the same time, and achieve the effect of reducing the process of spraying and baking, saving the cost of painting and reducing the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

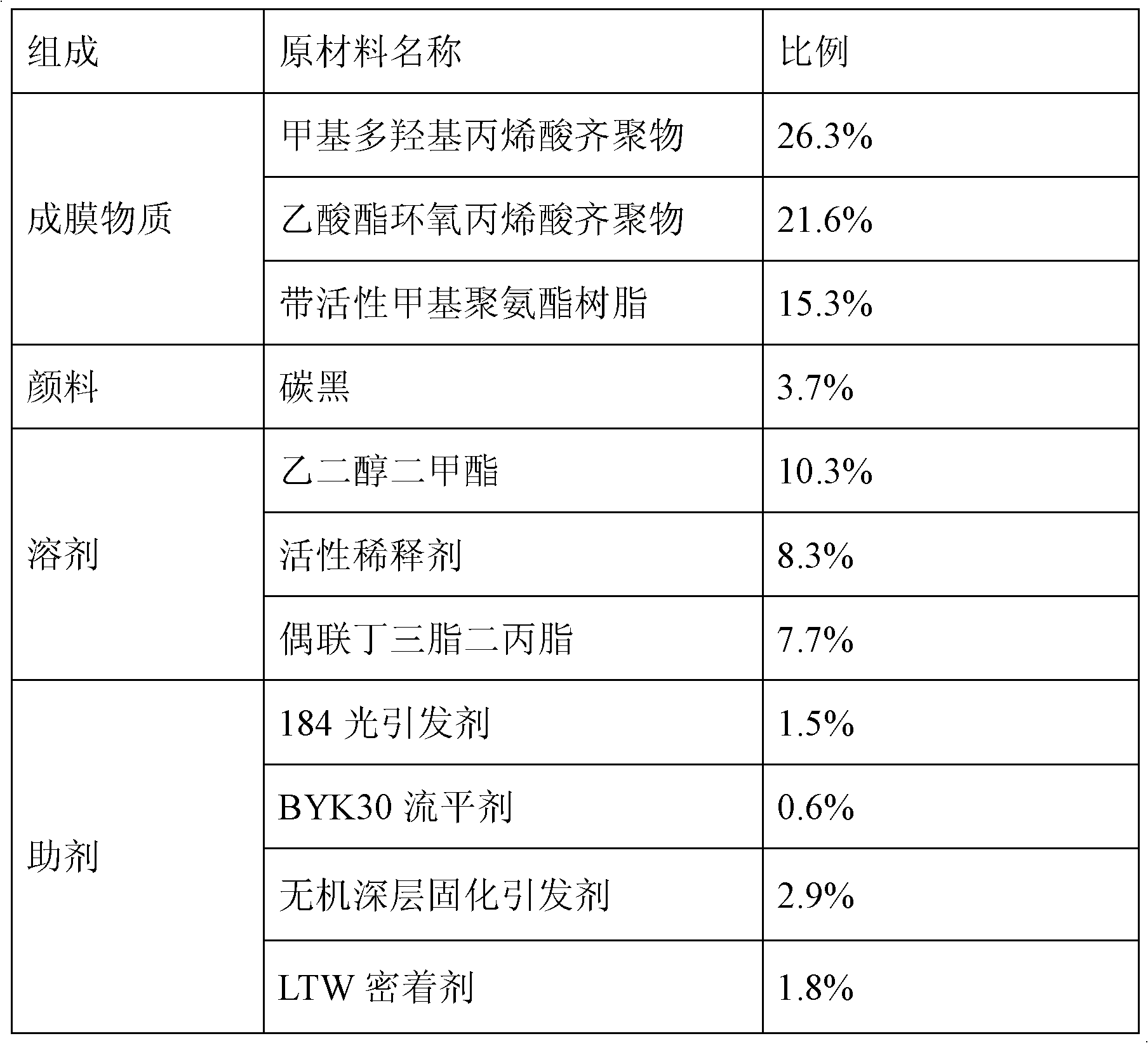

[0022] The component weight ratios of colored UV coatings are shown in Table 1. In the case of the weight component ratios in Table 1, the adhesion of colored UV coatings was tested.

[0023] Table 1

[0024]

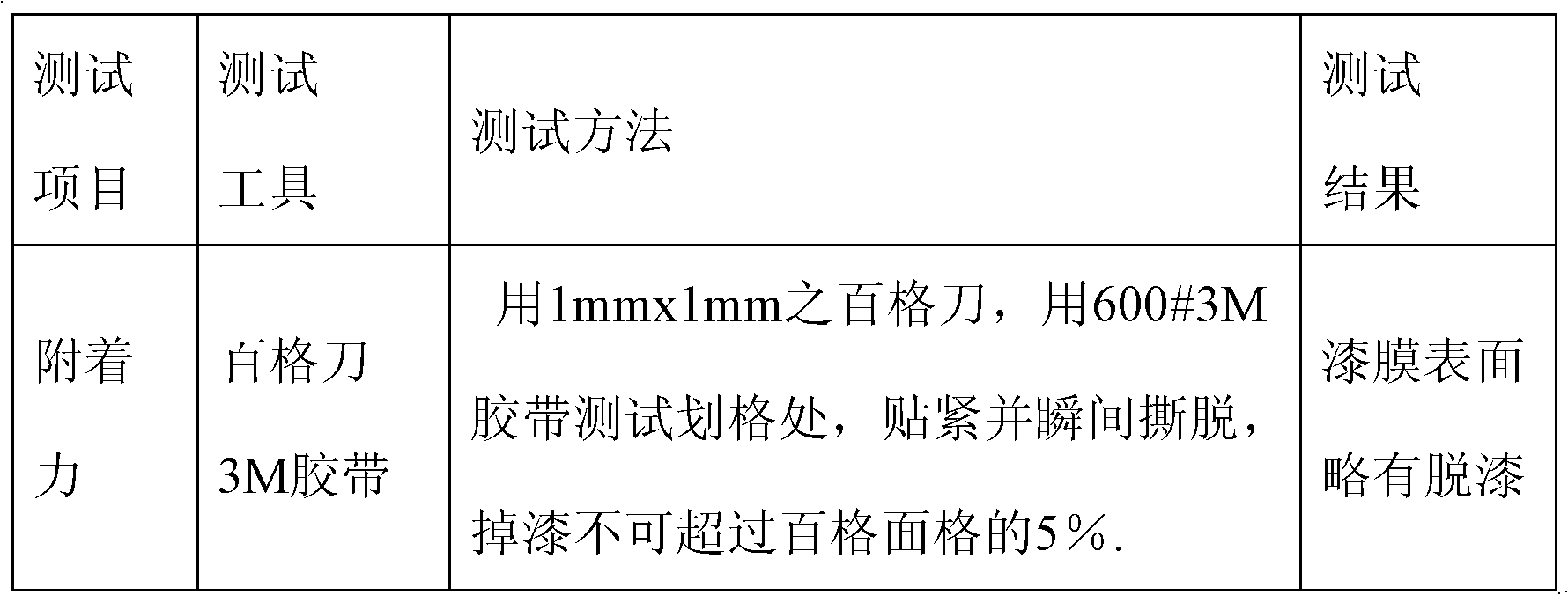

[0025] Under the weight ratio of the colored UV coating component of table 1, the result of test adhesion is as table 2;

[0026] Table 2

[0027]

[0028] As shown in Table 1 and Table 2, the weight ratio of the methyl polyhydroxyacrylic acid oligomer is 26.3%, the weight ratio of the active methyl polyurethane resin is 15.3%, the weight ratio of carbon black is 3.7%, and the inorganic deep layer curing When the weight ratio of the initiator is 2.9%, and the weight ratio of the adhesive agent is 1.8%, the experimental result shows that the surface of the paint film is slightly peeled off.

Embodiment 2

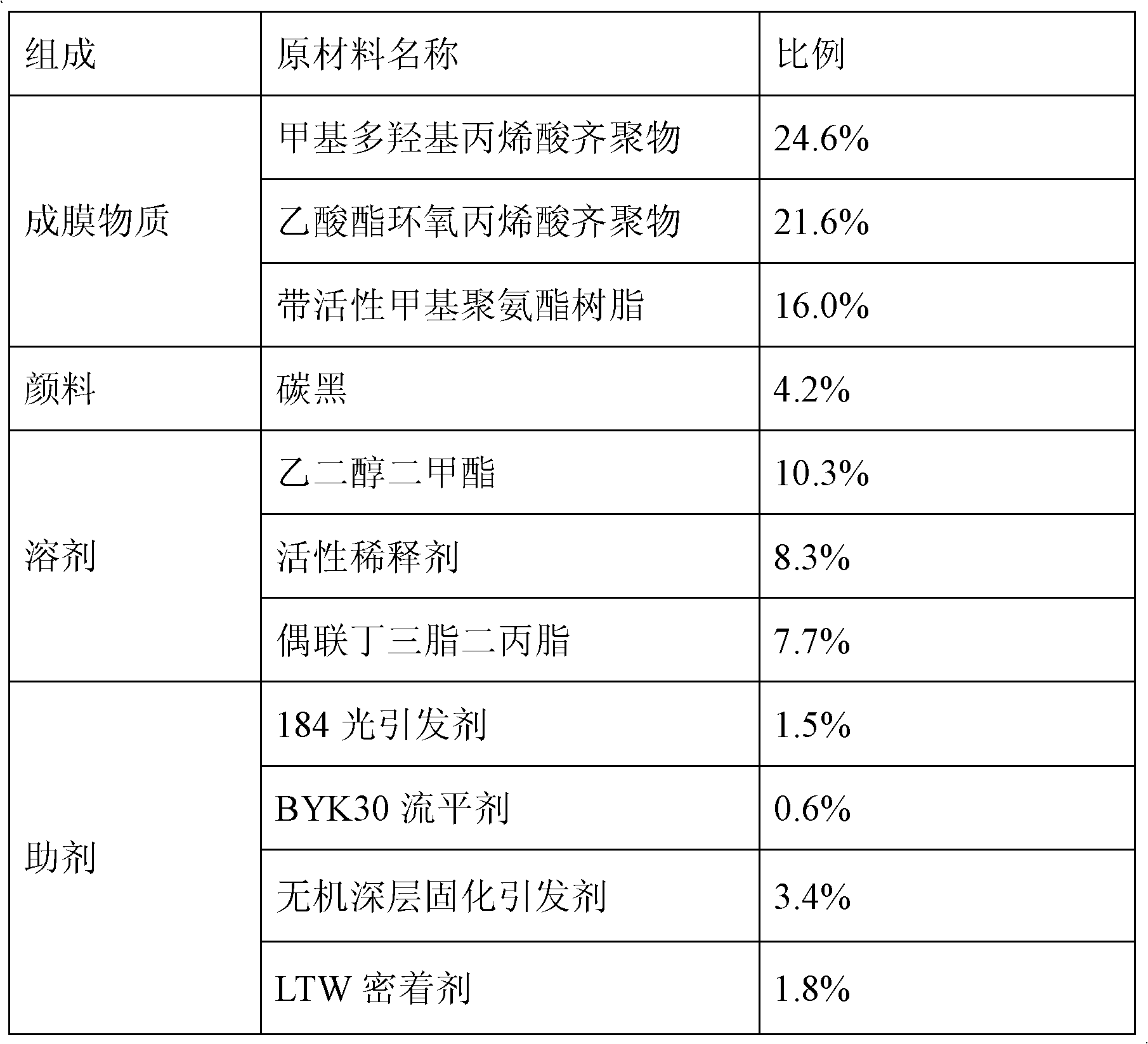

[0030] The component weight ratios of colored UV coatings are shown in Table 3. In the case of the weight component ratios in Table 3, the adhesion of colored UV coatings was tested.

[0031] table 3

[0032]

[0033] Under the weight ratio of the colored UV coating of table 3, the result of test adhesion is as table 4;

[0034] Table 4

[0035]

[0036]

[0037] As shown in Table 3 and Table 4, the weight ratio of the methyl polyhydroxyacrylic acid oligomer is 24.6%, the weight ratio of the active methyl polyurethane resin is 15.7%, and the weight ratio of carbon black is 4.2%. When the weight ratio of the initiator is 3.4%, and the weight ratio of the adhesive agent is 2.1%, the experimental results show that there is no paint peeling on the surface of the paint film.

Embodiment 3

[0039] The component weight ratios of colored UV coatings are shown in Table 5. In the case of the weight component ratios in Table 5, the adhesion of colored UV coatings was tested.

[0040] table 5

[0041]

[0042]

[0043] Under the weight ratio of the colored UV coating of table 5, the result of test adhesion is as table 6;

[0044] Table 6

[0045]

[0046] As shown in Table 5 and Table 6, the weight ratio of the methyl polyhydroxyacrylic acid oligomer is 22.6%, the weight ratio of the active methyl polyurethane resin is 17.7%, the weight ratio of carbon black is 3.9%, and the inorganic deep layer curing When the proportion by weight of the initiator is 3.8%, and the proportion by weight of the adhesive is 2.5%, the experimental results show that the surface of the paint film has a slight paint peeling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com