Crude oil viscosity reducing device and preparation method of crude oil viscosity reducing device

A technology for reducing viscosity and crude oil, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor flow ability of heavy oil, and achieve the effects of lowering freezing point, prolonging pump inspection cycle, and reducing operation times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

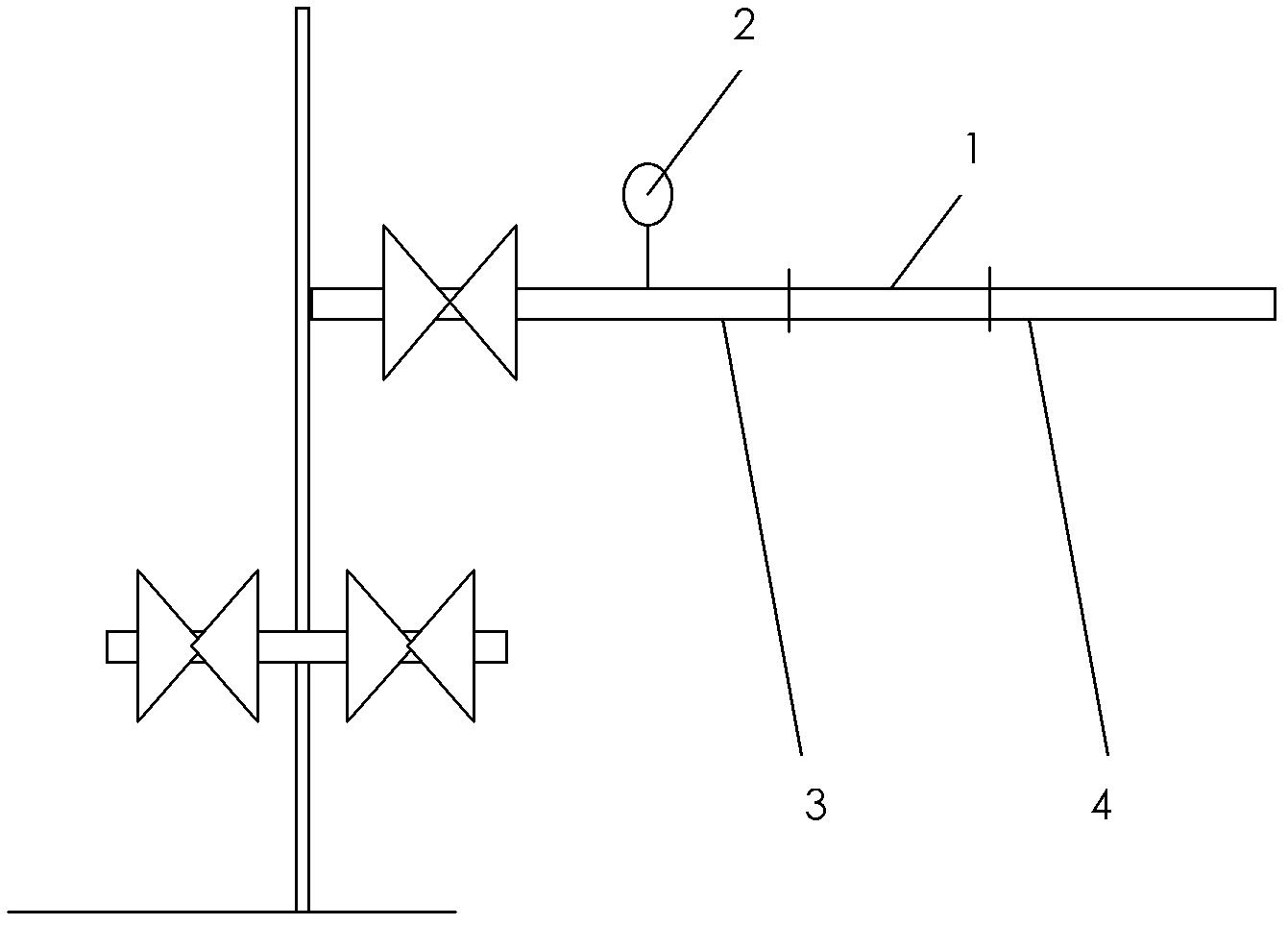

Image

Examples

Embodiment 1

[0015] The crude oil viscosity reducer of the present invention is composed of a rod-shaped alloy body, the rod-shaped alloy body is composed of magnet steel and rare earth elements, and the rare earth elements are composed of cerium group elements, yttrium group elements and scandium elements , the weight ratio between the cerium group element, yttrium group element, scandium element and the magnetic steel is 4-6:3-4:1-2:20, and the cerium group element is composed of cerium element, praseodymium element, Neodymium element and samarium element, in the cerium group elements, the weight ratio of the cerium element, praseodymium element, neodymium element and samarium element is 0.8~1.2:0.8~1.2:1.8~2.2:0.8~1.2, the described The yttrium group element is composed of holmium element, erbium element and dysprosium element, and in the yttrium group element, the weight ratio of the holmium element, erbium element and dysprosium element is 1.3-1.8:0.4-0.6:1.3-1.8.

[0016] Further, th...

Embodiment 2

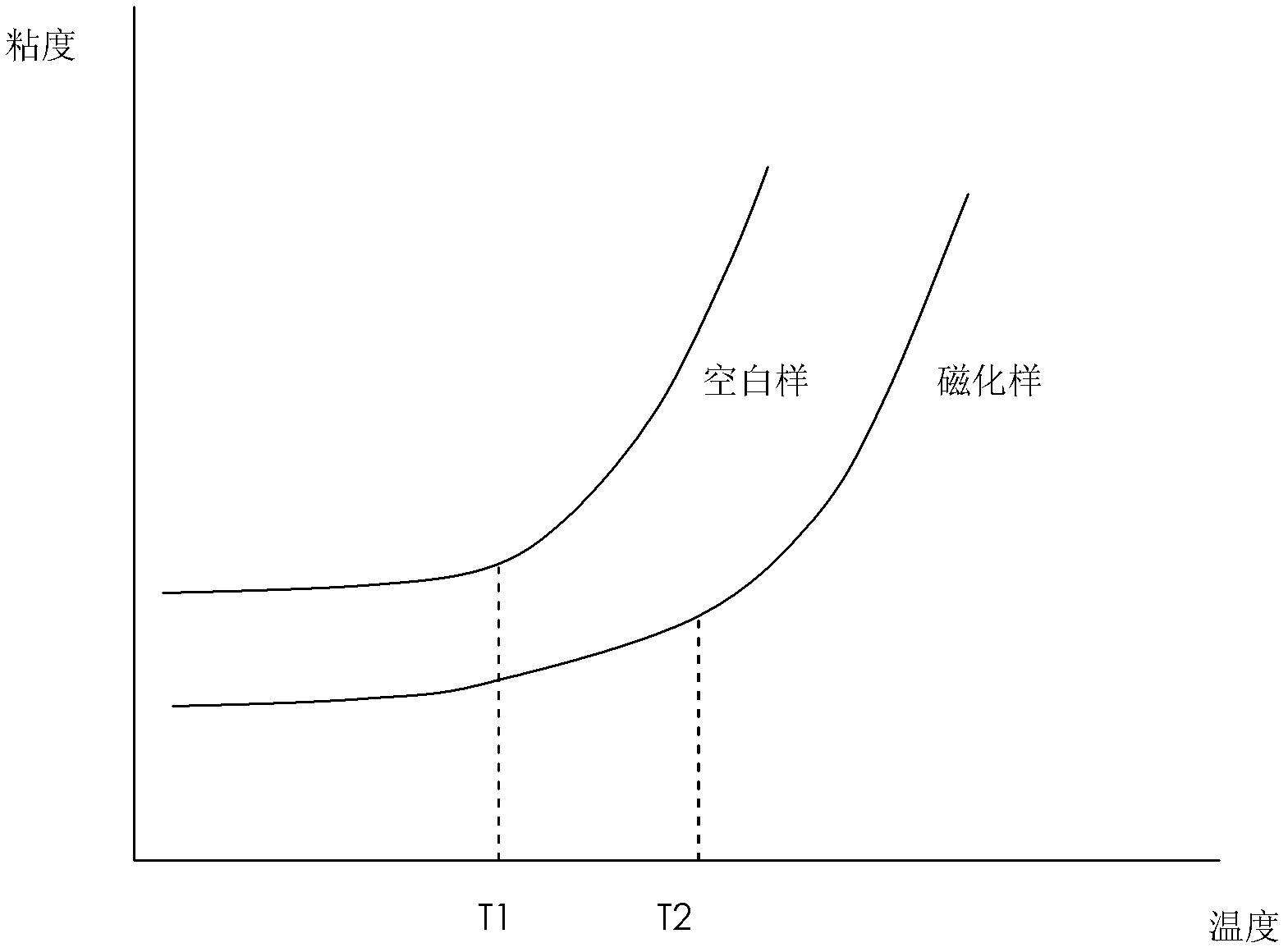

[0022] The viscosity reduction test of the crude oil viscosity reducer of the present invention is as follows:

[0023] The oil wells in an oilfield have serious wax deposition and high viscosity, which requires frequent hot washing of the oil pipelines, which increases the cost of crude oil production. These wells account for 90% of the total number of wells in operation.

[0024] In order to explore a simple method of magnetic anti-wax viscosity reduction and reduce the number of hot washes of the oil pipeline, the inventor conducted a research on wellhead magnetic viscosity reduction in an oil field.

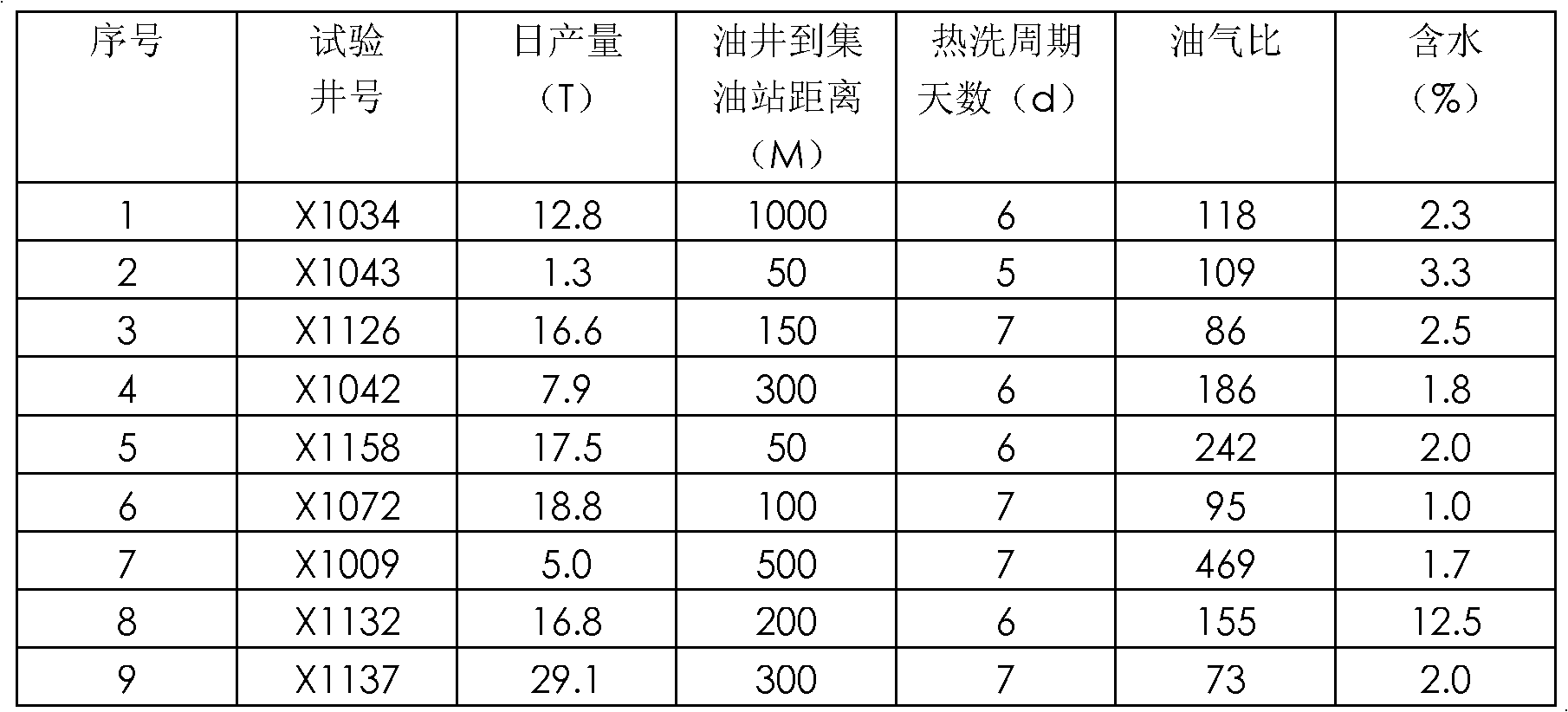

[0025] Table 1: Basic conditions of the wellhead strong magnetic wax anti-wax viscosity reduction test well in an oilfield

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com