Top-spraying self-priming regeneration tower

A self-priming, regeneration tower technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problem of insufficient separation time of solution and sulfur bubbles, insufficient separation time of sulfur bubbles and solution, and desulfurization absorption reaction. Insufficient time and other problems, to achieve the effect of stable and easy-to-control desulfurization operation, eliminating the need for special air compressors, good economic benefits and social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments.

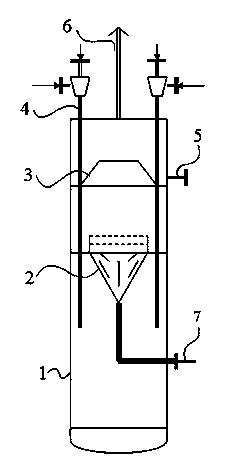

[0022] Such as figure 1 As shown, the tower body 1 of the top-spray self-priming regeneration tower is cylindrical in shape, and a foam separator 2 is arranged in the tower body 1; a foam collection weir is arranged in the tower body 1 between the foam separator 2 and the top of the tower 3. A sulfur bubble outlet pipe 5 is provided on the tower body 1 between the foam separator 2 and the top of the tower; a self-priming jet regenerator 4 is arranged on the tower, and the solution outlet at the lower end of the self-priming jet regenerator 4 is in the foam Between the separator 2 and the bottom of the tower, the solution outlet of the self-priming jet regenerator is connected to the solution outlet pipe 7, and the solution outlet pipe 7 is a "Π" shaped pipe. A regeneration waste gas discharge pipe 6 is arranged on the top of the tower, and nozzles for cleaning the waste ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com