Method for preparing film material by coating polyvinylidene fluoride on glass fiber cloth

A glass fiber cloth, polyvinylidene fluoride technology, applied in fiber processing, textiles and papermaking, etc., can solve problems such as unreachable, and achieve the effects of small smoke generation, improved high temperature resistance, and good self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

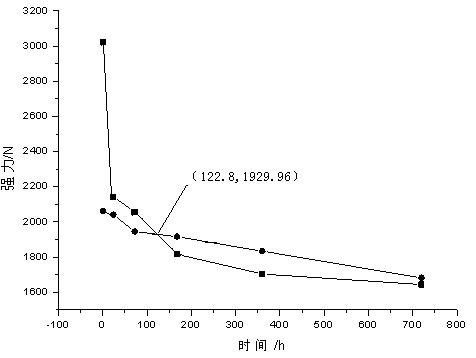

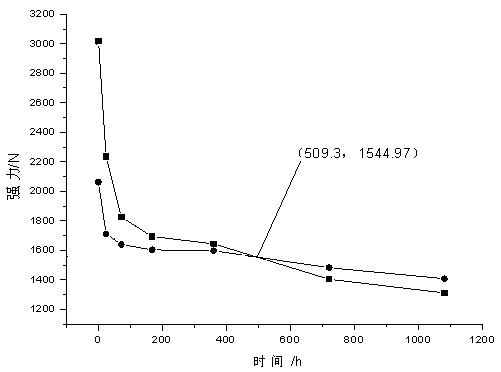

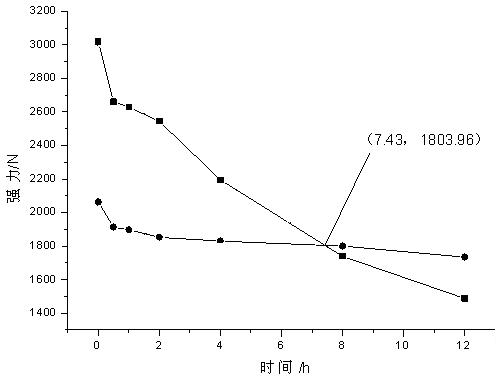

Image

Examples

Embodiment Construction

[0022] 1. Preparation of polyvinylidene fluoride latex

[0023] Polyvinylidene fluoride latex embodiment formula is as follows:

[0024] Table 1

[0025]

[0026] According to the formula in the above table, each component was mixed uniformly to obtain the polyvinylidene fluoride latex of each embodiment.

[0027] 2. Preparation of finished products

[0028] The present invention selects conventional non-alkali tank kiln EW430 (3732) type glass fiber gray cloth as the base material of PVDF film, selects the latex that above-mentioned example 6 makes for use, adopts imported KR-RA type glue scraping machine, carries out the production experiment of sample. First, a layer of polyorganosiloxane resin coated on the lower surface of the glass fiber cloth, the coating amount is 53g / m 2 , the drying temperature is set to 170°C, and the polyvinylidene fluoride latex prepared in the above example 6 is also coated on the upper surface of the glass fiber cloth, and the coating amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| Continue burning | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com