A high temperature resistant blended yarn and its production process

A technology of blended yarn and high temperature resistance, which is applied in the field of textile yarn, and can solve the problems of not having the function of anti-oil pollution and small application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

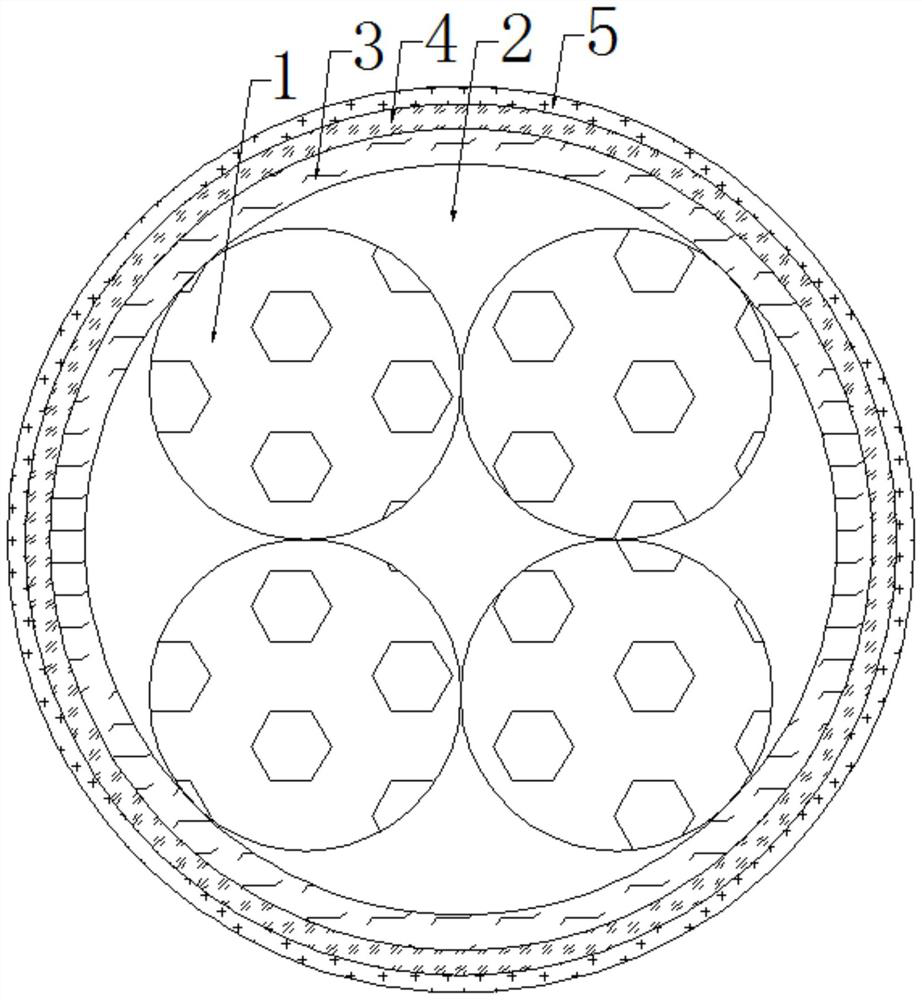

[0038]A high temperature-resistant blended yarn, comprising an outer layer and a core layer, the outer layer is covered on the core layer, and the outer layer includes a flame-retardant layer, an oil-proof layer and a skin layer polymer arranged from the inside to the outside, The core layer includes a main core wire, which is formed by blending polyimide fiber and polyether ketone, and the temperature-regulating viscose fiber is also filled between the main core wire and the flame-retardant layer. Among them, the outer layer is provided with an oil-repellent layer and a cortex polymer. When the yarn product is exposed to oil stains, the peripheral cortex polymer plays the role of oleophobic and water-repellent, thereby preventing oil stains from immersing; Further oil repellency. The flame-retardant layer is set to prevent the yarn from burning to the core wire and causing damage to the core layer when the yarn catches fire. In addition, the temperature-regulating viscose fib...

Embodiment 2

[0040] On the basis of Example 1, the skin layer polymer is a fluorine-containing polyurethane-acrylate polymer, and the contact angle of the fabric surface treated by the polymer can reach 136° to water, and the contact angle to paraffin oil It can reach 120°, which can greatly improve the hydrophobicity and oleophobicity of the treated fabric, so the oil-proof performance of the yarn is greatly guaranteed.

Embodiment 3

[0042] On the basis of Example 1, the oil-repellent layer is bamboo fiber. Bamboo fiber has the characteristics of non-sticking oil, which can further enhance the oil resistance of the yarn; bamboo fiber also has good air permeability, strong wear resistance, antibacterial, antibacterial, and deodorant functions, so the yarn has very good properties. Strong practicality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com