Method for dyeing pure silk by regarding rare earth material as mordant

A dyeing method and technology for real silk, applied in the direction of dyeing, animal fibers, textiles and paper making, etc., can solve the problems of low fiber affinity, improve the dyeing fastness, increase the dyeing percentage, and improve the apparent color depth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

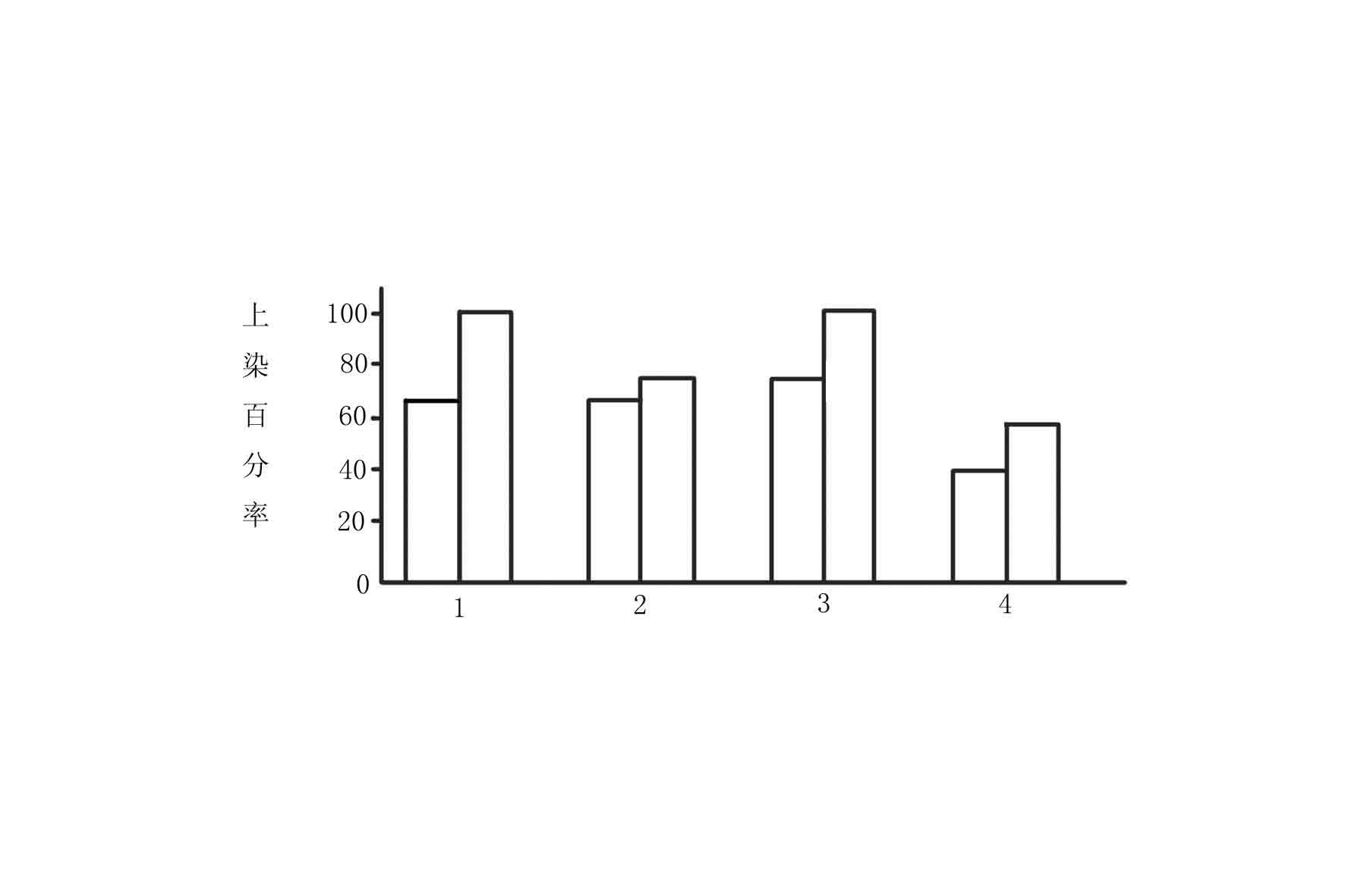

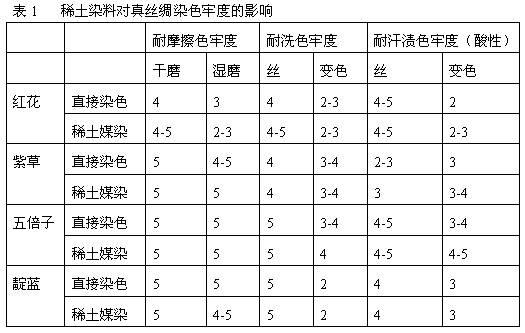

Image

Examples

Embodiment 1

[0021] Embodiment 1 is the real silk dyeing method of mordant dyeing agent with rare earth substance

[0022] Proceed as follows:

[0023] 1) Pretreatment: Take the bleaching solution according to the bath ratio of 1:30, raise the temperature of the bleaching solution to 98°C, add silk, keep the temperature at 98°C, and soak for 30 minutes; the composition of the bleaching solution is: add 10g hydrogen peroxide, 2.5g soda ash, 2g flat plus O and 3g sodium silicate;

[0024] 2) Washing: washing the pretreated silk with water for 3 times; the washing liquid is: take clear water and use acetic acid to adjust the pH to 6;

[0025] 3) Dehydration: After washing, dehydrate and dry;

[0026] 4) Dyeing

[0027] Preparation of dye solution: add 1.5g plant dye safflower per 1 liter of water;

[0028] Preparation of rare earth solution: add 0.8g of rare earth substance Ce to every 1 liter of dyeing solution 2 (C0 3 ) 3 Calculate, accurately weigh a certain amount of rare earth...

Embodiment 2

[0034] Embodiment 2 is the real silk dyeing method of mordant dyeing agent with rare earth substance

[0035] Proceed as follows:

[0036] 1) Pretreatment: Take the bleaching solution at a bath ratio of 1:35, raise the temperature of the bleaching solution to 98°C, add silk, keep the temperature at 98°C, and soak for 40 minutes; the composition of the bleaching solution is: add 15g hydrogen peroxide, 3g soda ash, 2.5g flat plus O and 4g sodium silicate;

[0037] 2) Washing: washing the pretreated silk with water for 3 times; the washing liquid is: take clear water and use acetic acid to adjust the pH to 6.5;

[0038] 3) Dehydration: After washing, dehydrate and dry;

[0039] 4) Dyeing:

[0040] The preparation of the dye solution: add 7g of plant dye comfrey to every 1 liter of water;

[0041] Preparation of rare earth solution: add 1.0g of rare earth substance La to every 1 liter of dye solution 2 0 3 Calculate, accurately weigh a certain amount of rare earth substanc...

Embodiment 3

[0047] Embodiment 3 is the real silk dyeing method of mordant dyeing agent with rare earth substance

[0048] Proceed as follows

[0049] 1) Pretreatment: Take the bleaching solution according to the bath ratio of 1:25, raise the temperature of the bleaching solution to 98°C, add silk, keep the temperature at 98°C, and soak for 30 minutes; the composition of the bleaching solution is: add 5g hydrogen peroxide, 2g soda ash, 1.5g flat plus O and 2 sodium silicate;

[0050] 2) Water washing: wash the pretreated silk twice with water washing solution; the washing solution is: take clear water and use acetic acid to adjust the pH to 5.5;

[0051] 3) Dehydration: After washing, dehydrate and dry;

[0052] 4) Dyeing

[0053] Preparation of dye solution: add 0.05g vegetable dye Galla per 1 liter of water;

[0054] Preparation of rare earth solution: add 0.5g of rare earth substance Pr per 1 liter of dye solution 2 0 3 Calculate, accurately weigh a certain amount of rare eart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com