Water cooling-heating rubber floor

A rubber water, hot and cold technology, applied in the field of flooring, can solve the problems of endangering human health, lack of heating and cooling functions, single floor functions, etc., and achieve the effects of reducing energy consumption, convenient replacement, and increased wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

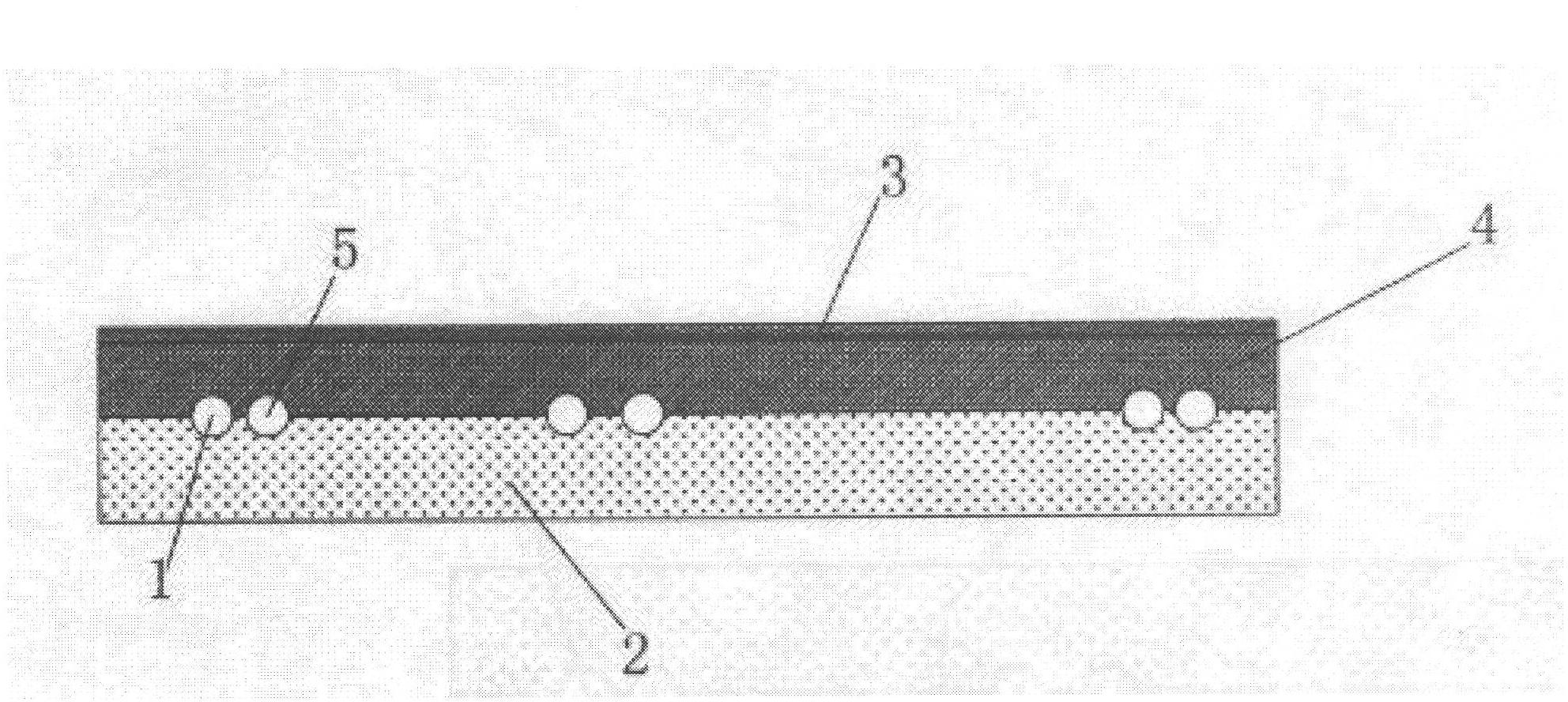

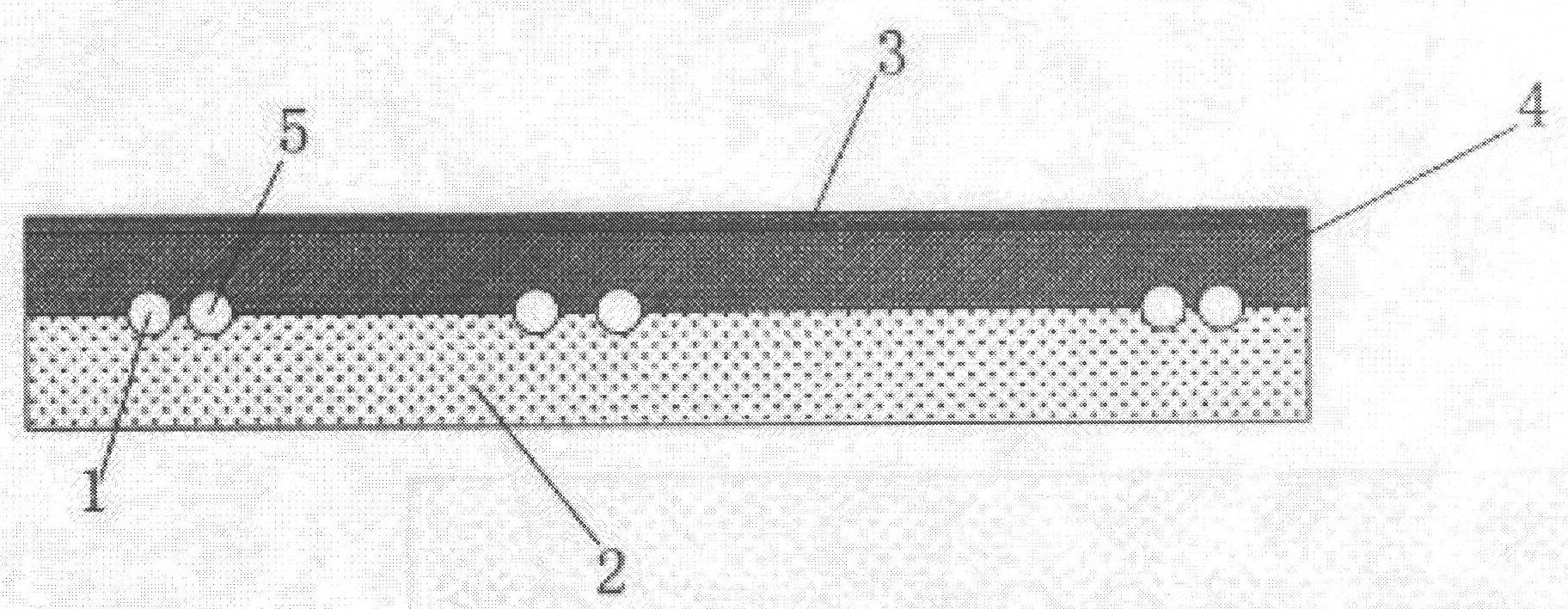

[0020] A rubber water-cooled and heated floor, the length and width of which are 5000mm, the thickness is 60mm, and the hardness is Shore A 30-98, which is composed of a wear-resistant rubber layer 3, a heat-conducting rubber layer 4, and a foamed rubber layer 2 connected up and down in sequence , wherein the heat-conducting rubber layer 4 and the foam rubber layer 2 are provided with a water inlet pipe 1 and a water return pipe 5, and the wear-resistant rubber layer 3 is made of silicone rubber SIL, nitrile rubber NBR, hydrogenated nitrile rubber HNBR, fluorine rubber FKM, fluorine Silicone rubber FLS, EPDM EPDM, neoprene CR, natural rubber NR, polyurethane rubber PU, styrene-butadiene rubber SBR, butyl rubber TIR, acrylate rubber ACM, wear-resistant rubber layer 3 added Wear-resistant agent, with a thickness of 10mm, is vulcanized simultaneously with the heat-conducting rubber layer 4. The surface of the wear-resistant rubber layer 3 is provided with various patterns of conca...

Embodiment 2

[0022] A rubber water-cooled and heated floor, the length and width of which are 500mm, the thickness is 10mm, and the hardness is Shore A30-98. It is composed of a wear-resistant rubber layer 3, a heat-conducting rubber layer 4, and a foamed rubber layer 2. Wherein, a water inlet pipe 1 and a water return pipe 5 are provided between the heat-conducting rubber layer 4 and the foam rubber layer 2, and the wear-resistant rubber layer 3 is made of natural rubber NR, and the wear-resistant rubber layer 3 is added with wear-resistant agent, with a thickness of 1mm. Simultaneously vulcanized with the heat-conducting rubber layer 4, the wear-resistant rubber layer 3 is provided with a diamond pattern, the heat-conducting rubber layer 4 is made of silicone rubber SIL, and the heat-conducting rubber layer 4 is added with a heat-conducting agent, the thickness is 4mm, no foaming, and the foaming rubber layer 2 Simultaneous vulcanization, the foamed rubber layer 2 is made of nitrile rubbe...

Embodiment 3

[0024] A rubber water-cooled and heated floor, with a length and width of 1000mm, a thickness of 54mm, and a hardness of Shore A 30-98. , wherein the heat-conducting rubber layer 4 and the foam rubber layer 2 are provided with a water inlet pipe 1 and a water return pipe 5, and the wear-resistant rubber layer 3 is made of silicone rubber SIL, fluororubber FKM, fluorosilicone rubber FLS, natural rubber NR, styrene-butadiene rubber It is made of SBR compounding, the wear-resistant rubber layer 3 is added with wear-resistant agent, the thickness is 2mm, it is bonded with the heat-conducting rubber layer 4 with an adhesive, and the surface of the wear-resistant rubber layer is bonded with various synthetic fibers and natural fibers with adhesives Made into a carpet type, the fiber height is 5mm, and the heat-conducting rubber layer 4 is made of NBR, EPDM, CR, polyurethane rubber, styrene-butadiene rubber SBR, and acrylic rubber ACM. The rubber layer 4 is added with thermal conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com