Vehicle-mounted one-key constant-frequency power generation system and vehicle-mounted one-key constant-frequency power generation control system and method

A technology of constant frequency power generation and control system, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of large inertia of alternator, high failure rate of electrical equipment, poor reliability, etc., to achieve simple operation and protection. The effect of electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

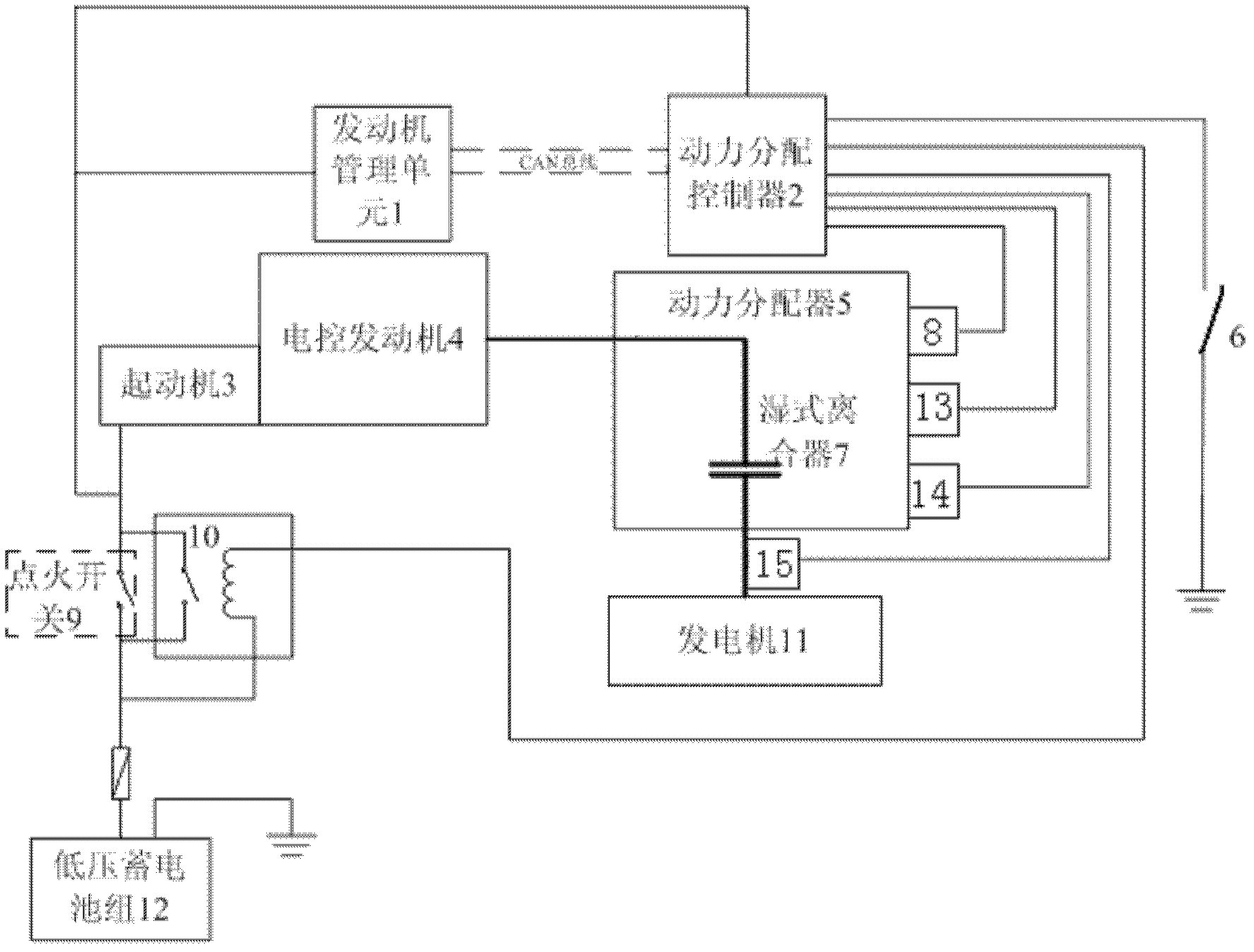

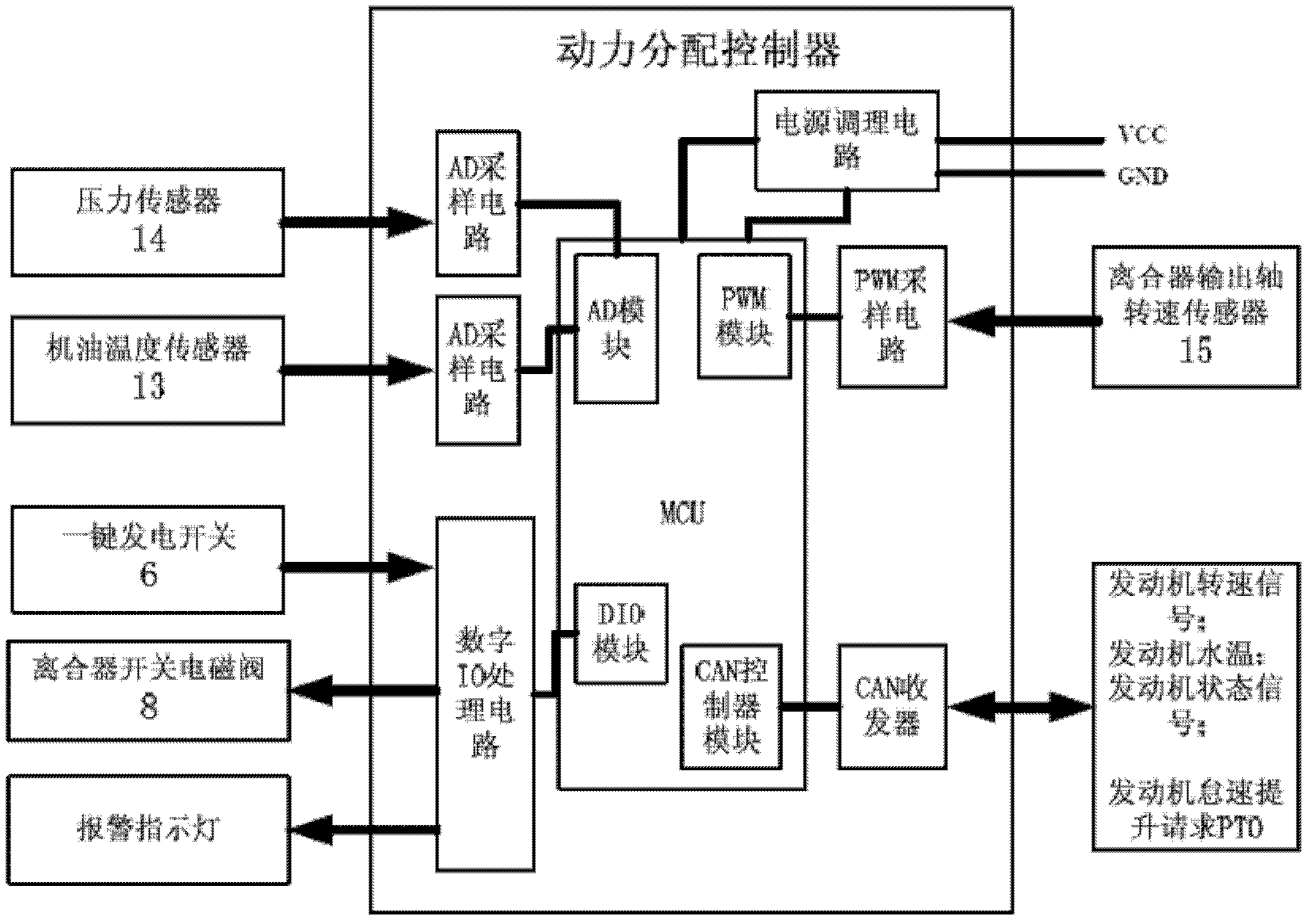

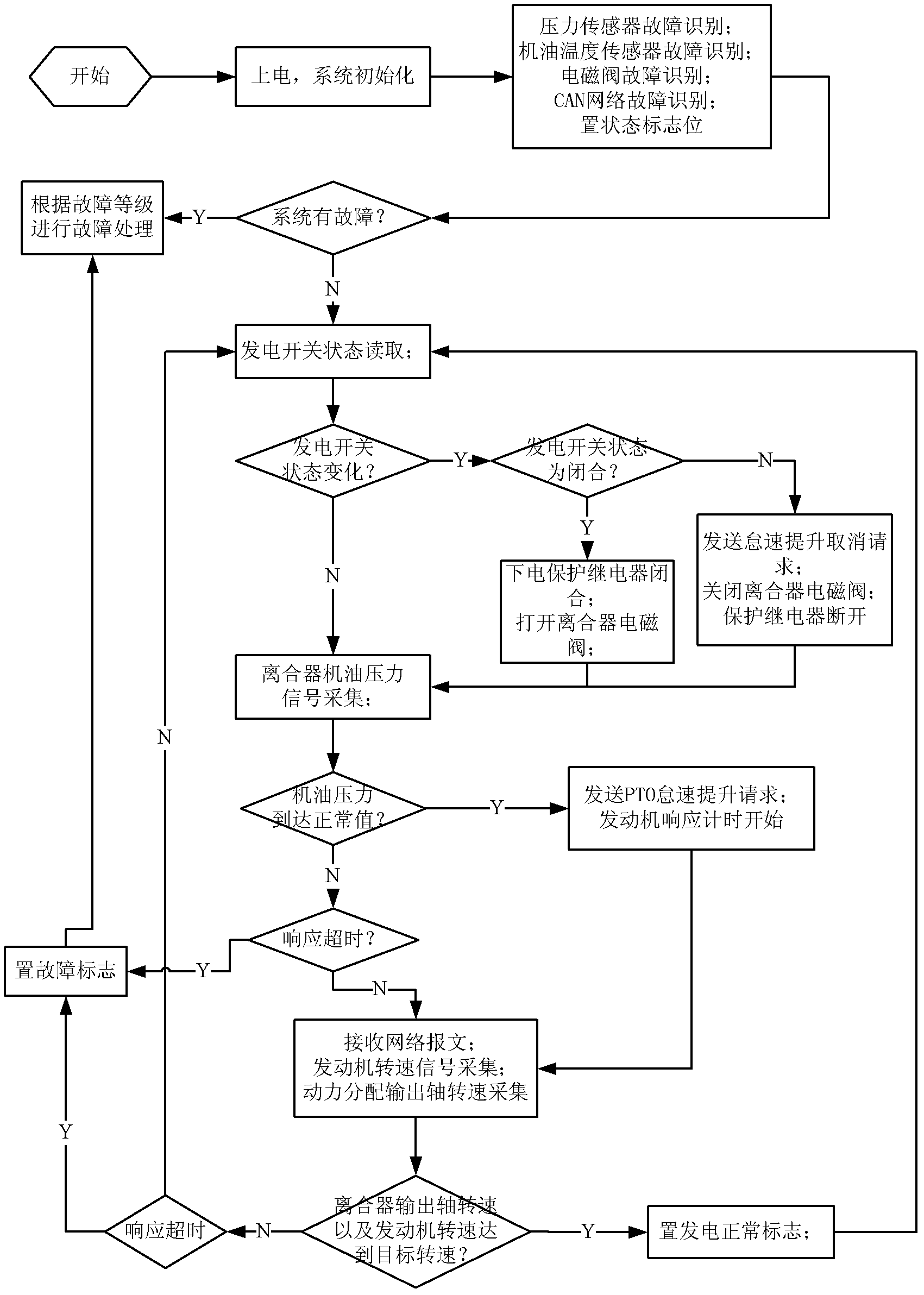

[0020] like figure 1 As shown, a vehicle-mounted one-button constant frequency power generation system of the present invention includes an engine management unit 1, an electronically controlled engine 4, a starter 3, a power splitter 5, a wet clutch 7, a clutch switch solenoid valve 8, and an alternator 11 1. One key power generation switch 6, the starter 3 is connected with the electric control engine 4 through a belt drive, the electric control engine 4 is connected with the power splitter 5 through the output shaft, and the gear set inside the power splitter 5 outputs the power to the wet clutch 7, and the other end of the wet clutch 7 is connected with the alternator 11.

[0021] The power splitter 5 includes an input shaft, an intermediate shaft and a plurality of output shafts, and the transmission between the input shaft and the intermediate shaft is through a bevel gear, so that the input shaft and the output shaft are distributed along the vertical direction. A pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com