Absorption stage, placing stage and exposure apparatus

An adsorption table and adsorption hole technology, applied in the directions of screws, nuts, bolts, etc., can solve the problems of scratches on the surface of the workpiece, reduced product accuracy, and dust contamination of the workpiece, so as to prevent the reduction of product accuracy and the change of workpiece posture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

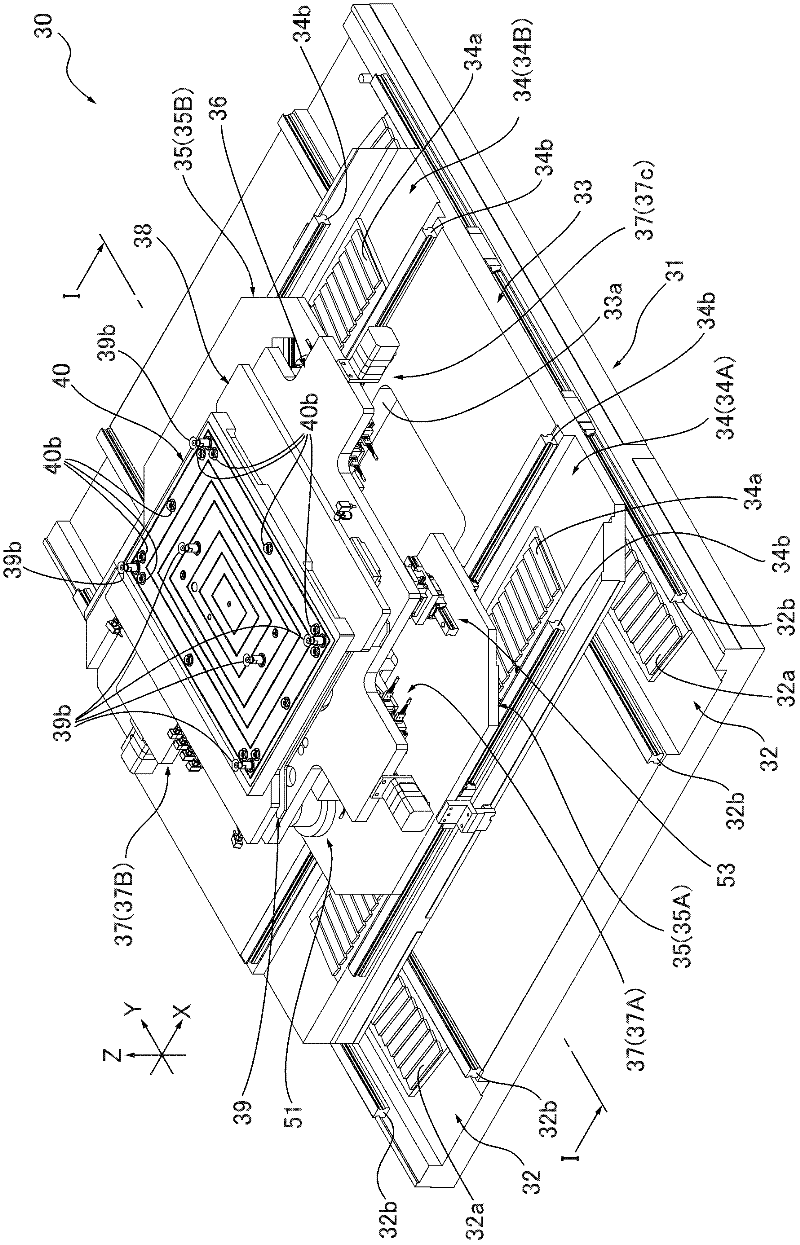

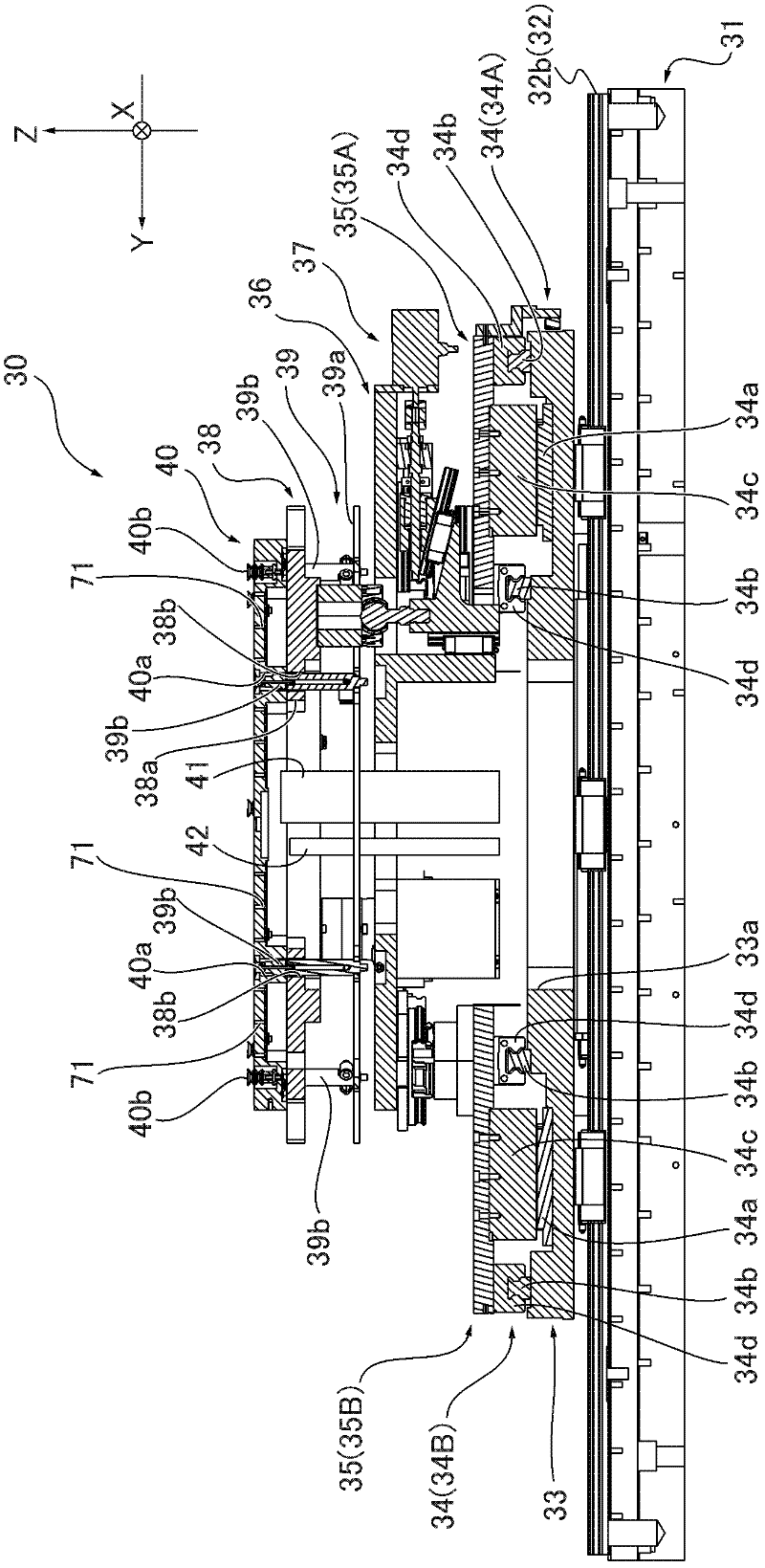

[0066] Next, an embodiment of the mounting table 30 according to the present invention will be described with reference to the drawings.

[0067] (Example)

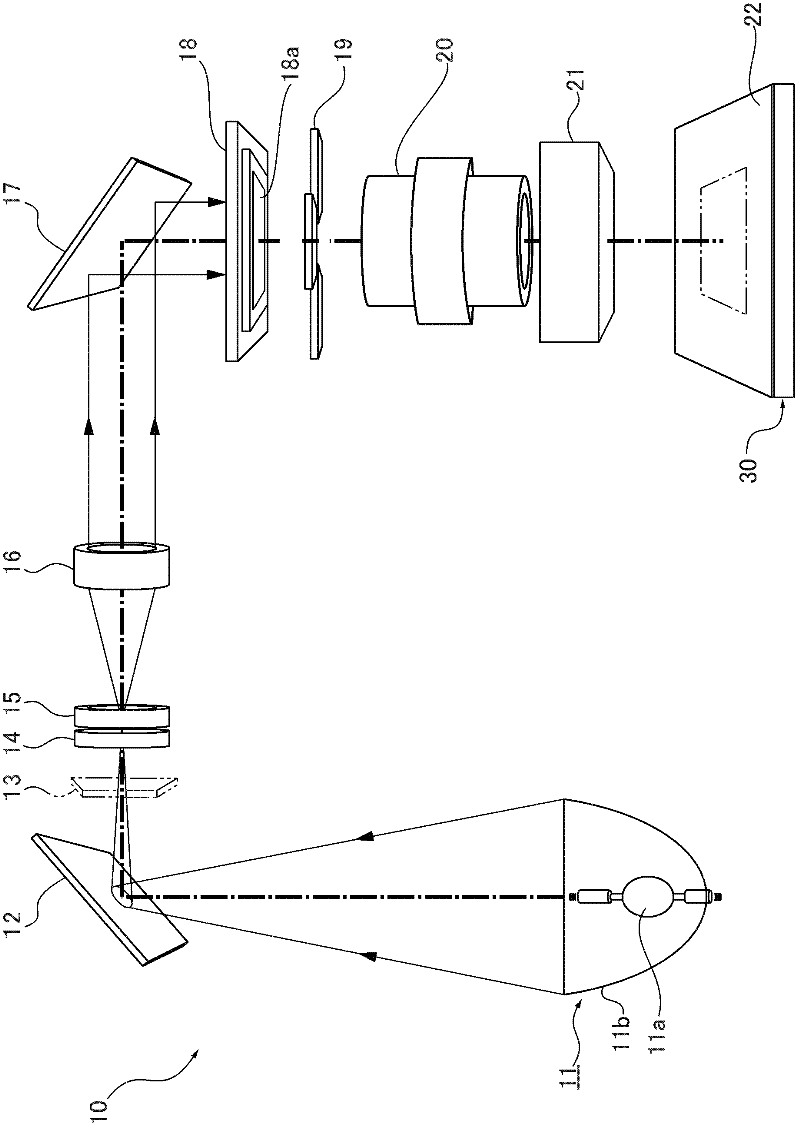

[0068] First, the schematic structure of the exposure apparatus 10 using the stage 30 which concerns on this invention is demonstrated. figure 1 It is an explanatory drawing which schematically shows the structure of the exposure apparatus 10 which is an example of the exposure apparatus concerning this invention. Exposure device 10 such as figure 1 As shown, there are in order from the exit side along the optical axis direction: a light source 11, a cold mirror 12, an exposure shutter 13, an ultraviolet bandpass filter 14, an integrating lens 15, a collimating lens 16, a plane mirror 17, a mask table 18, Mask blind section 19, projection lens 20, magnification correction section 21, and stage 30 (projection exposure stage). The exposure light of this exposure apparatus 10 uses ultraviolet rays.

[0069] The light sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com