Non-inductive coil for high-temperature superconducting resistance-type current restrictor

A technology of high-temperature superconducting and non-inductive coils, which is applied in superconducting magnets/coils, usage of superconducting elements, coil manufacturing, etc. To avoid problems such as large belt length, to achieve the effects of ensuring safety and stability, simplifying the structure, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] The present invention adopts the typical product dimensions of the commercially produced second-generation high-temperature superconducting tapes 12 and 13: the thickness is 0.1-0.3 mm, and the width is 4-12 mm. Under the condition of liquid nitrogen temperature and no external magnetic field, the critical current I of the high temperature superconducting strip 12, 13 unit width C Can reach 210A / cm.

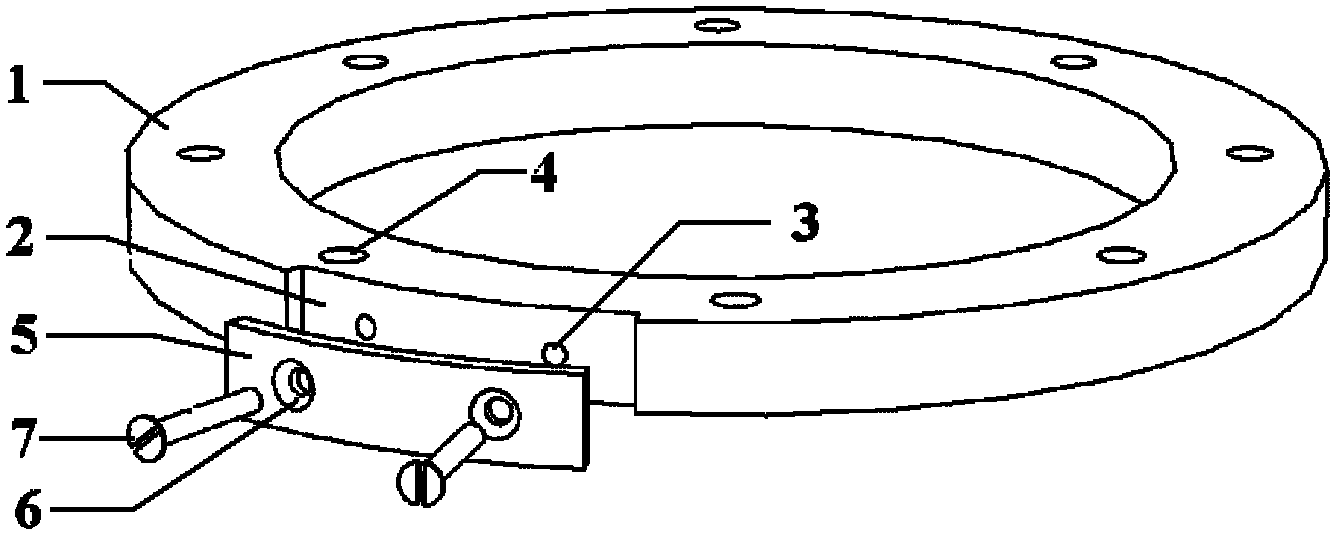

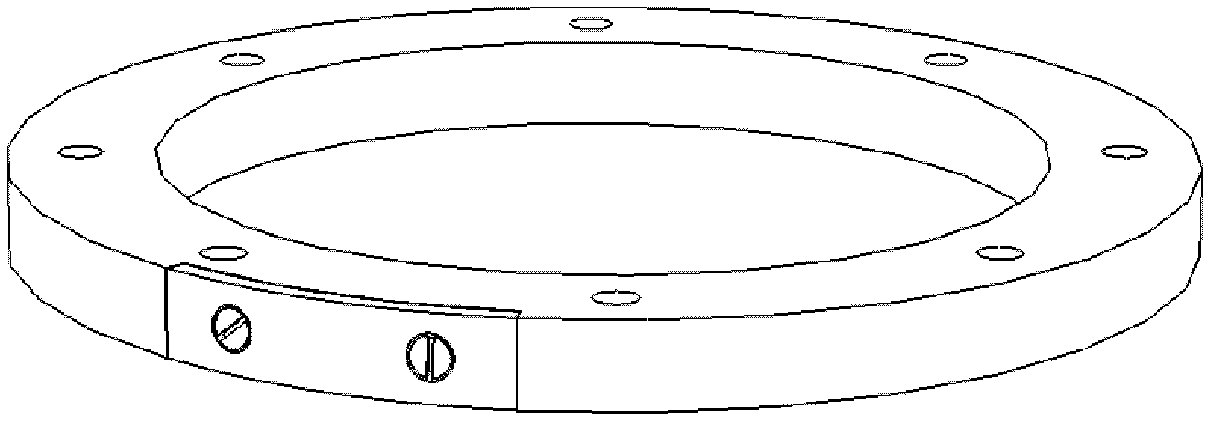

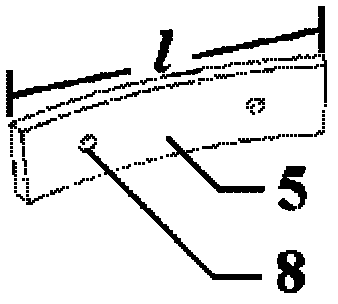

[0019] The present invention mainly includes a non-inductive cake-type coil skeleton 22 composed of a glass fiber reinforced plastic ring 1 and a copper connection piece 5, an inner high-temperature superconducting tape 12, an outer high-temperature superconducting tape 13, a spacer layer 14, lead terminals, coil splints and multiple sets of sinks. Parts such as head bolt 7,20,21.

[0020] The width of the copper connecting piece 5 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com