Method for producing nano fluorescent powder-free gallium nitride white light-emitting diode

A light-emitting diode, no phosphor technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as reducing the Droop effect and increasing the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] see figure 1 As shown in -6, the present invention provides a method for making a nano-phosphor gallium nitride white light-emitting diode, comprising the following steps:

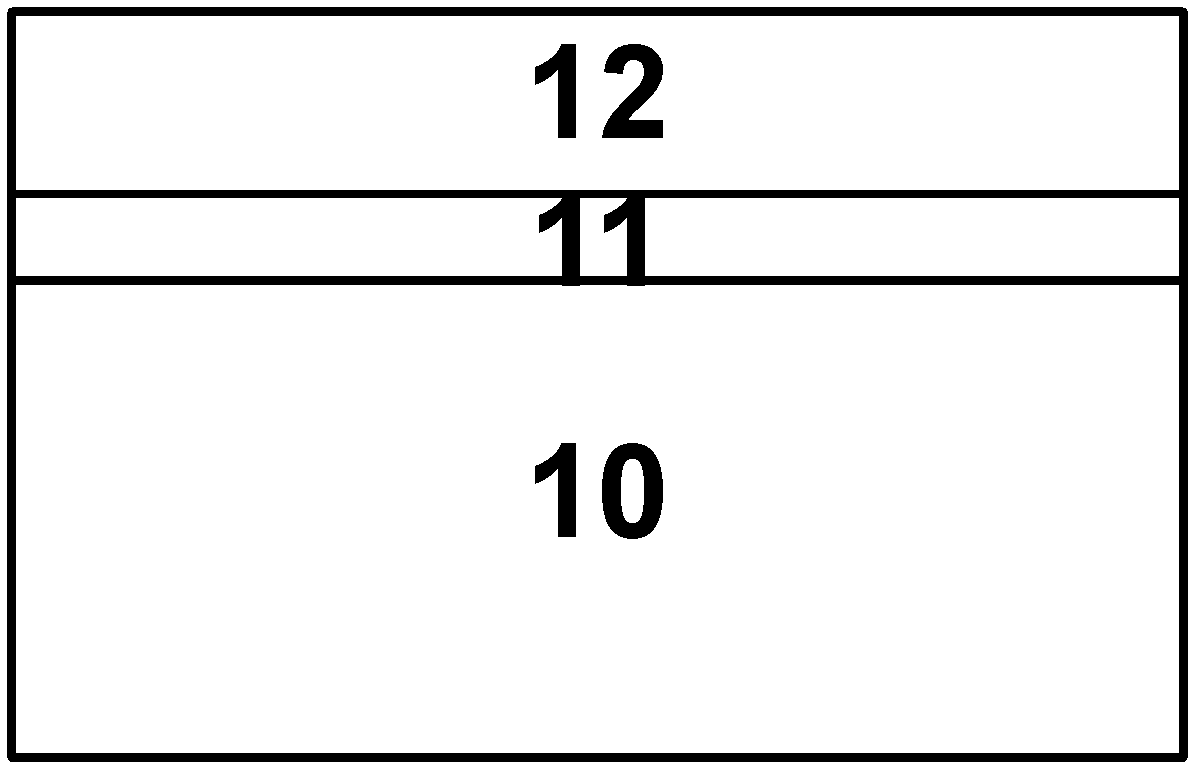

[0028] Step 1: Take a substrate 10, which is sapphire and has a thickness of 400um.

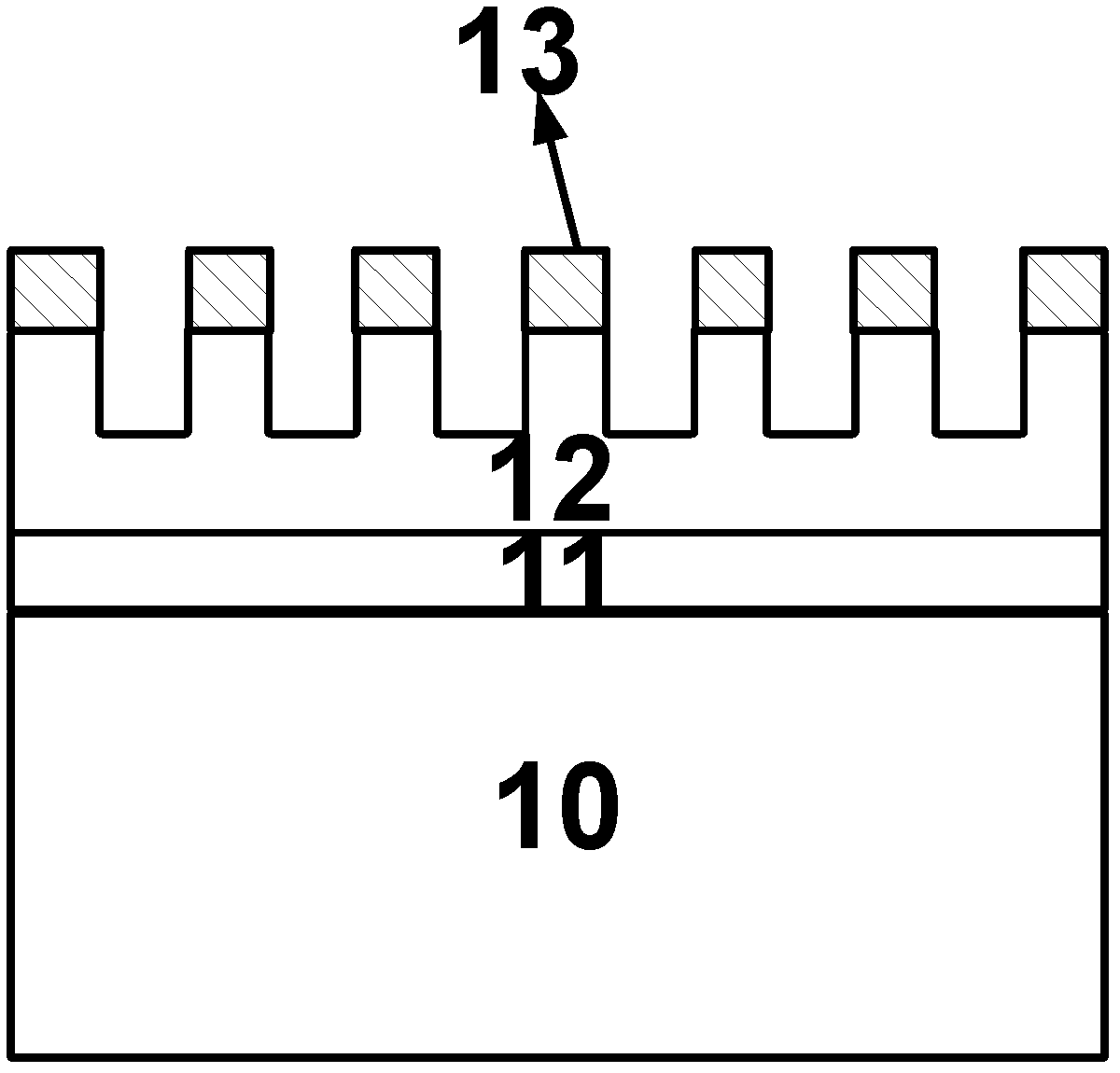

[0029] Step 2: GaN buffer layer 11 and n-GaN layer 12 are epitaxially grown on the substrate 10, the thicknesses of GaN buffer layer 11 and n-GaN layer 12 are 2um and 3um respectively.

[0030] Step 3: Fabricate a GaN nanowire template on the n-GaN layer 12 by nanotechnology. The size of the nano-pattern template is 100nm, and the depth is 500nm.

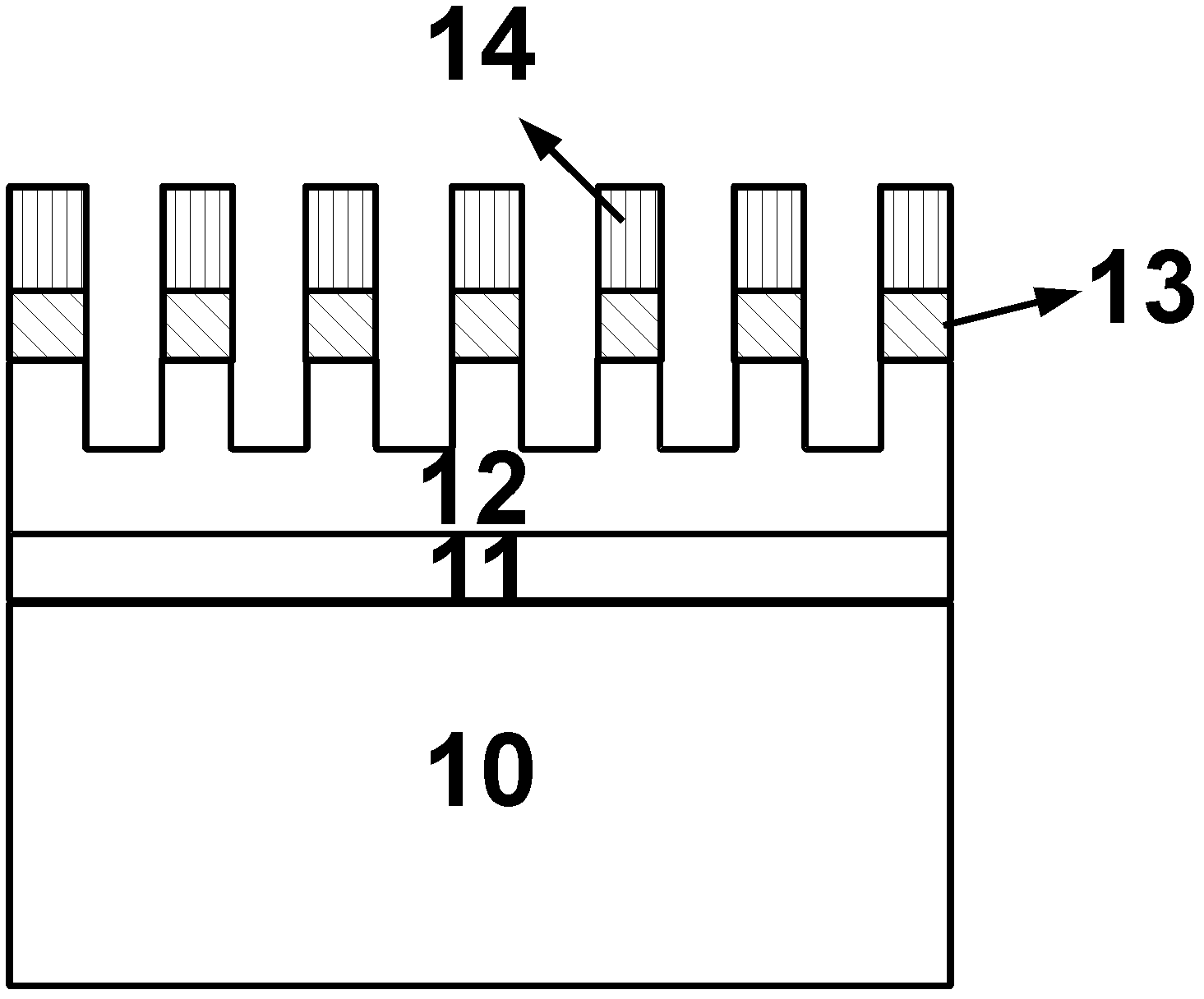

[0031] Step 4: growing a GaN transition layer 13 on the GaN nanowire template. The thickness of the GaN transition layer 13 is 20 nm.

[0032] Step 5: growing the InGaN quantum disk 14 on the GaN transition layer 14 . The InGaN quantum disk 14 is 5 groups of InGaN / GaN, and the variation of the In composition is 0.15-0.3.

[0033] Step 6: growing a p-GaN layer 15 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com