Method for preparing water-soluble ink jet dye

A water-soluble dye technology, applied in the direction of organic dyes, etc., can solve the problems of poor storage stability and achieve the effect of best storage stability and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Rhodamine B is used as the water-soluble primary dye.

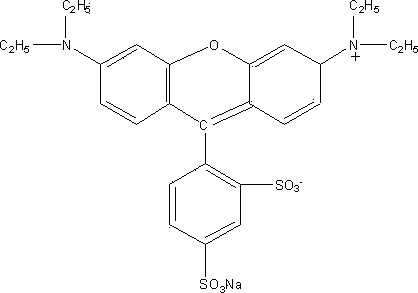

[0021] The structural formula of acid rose red B (C.I.Acid Red 52) is as follows:

[0022]

[0023] 4000 parts of deionized water, add 1000 parts of rhodamine B filter cake (water content: 40%), heat up to 50-60°C, and filter after complete dissolution. The filtrate is adjusted to PH=3 with dilute hydrochloric acid, desalinated by nanofiltration membrane (pressure 25bar, temperature 40-50°C), and after the chloride ion concentration is less than 2000mg / kg (converted to 500%), it is separated with triisopropanolamine solution. Adjust the pH of the dye solution in stages to 4.0, 5.0, 6.0, 7.0, continue desalting until the chloride ion concentration is less than 200 mg / kg (converted to 500%), concentrate to 2000 parts, and spray dry to obtain 660 parts of inkjet dye.

Embodiment 2

[0025] Rhodamine B is used as the water-soluble primary dye.

[0026] 4000 parts of deionized water, add 1500 parts of rhodamine B filter cake (water content: 40%), heat up to 50-60°C, and filter after complete dissolution. The filtrate is desalinated by nanofiltration membrane (pressure 25bar, temperature 40-50℃), after the chloride ion concentration is less than 5000mg / kg (converted into 200%), add 150 parts of triethanolamine, add 130 parts of hydrochloric acid (31%), continue Desalting until the chloride ion concentration is less than 200 mg / kg (converted to 500%), concentrated to 2000 parts, and spray-dried to obtain 400 parts of inkjet dye.

Embodiment 3

[0028] The water-soluble primary dye adopts direct turquoise blue FBL.

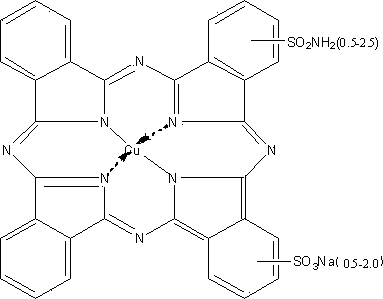

[0029] The structural formula of direct turquoise blue FBL (C.I.Direct Blue 199) is as follows:

[0030]

[0031] Add 1000 parts of direct turquoise blue FBL filter cake (48% water content) to 4000 parts of deionized water, heat up to 50-60 °C, and filter after completely dissolving. The filtrate is desalinated by nanofiltration membrane (pressure 30bar, temperature 40-50°C), after the chloride ion concentration is less than 5000mg / kg (converted into 200%), add 75 parts of diisopropanolamine, add hydrochloric acid (31%) 66 parts, continue desalting until the chloride ion concentration is less than 300 mg / kg (converted into 200%), concentrate to 1500 parts, and spray dry to obtain 460 parts of inkjet dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com