Electronically controlled electric six-speed automatic shift system

An automatic shifting, electric technology, applied in the direction of transmission, transmission control, components with teeth, etc., can solve the very high precision requirements of hydraulic component processing, the complex structure of electronic control-hydraulic system, the change of automobiles. Problems such as poor gear quality, to achieve the effect of solving the long sliding time, shortening the shifting time, and improving the shifting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

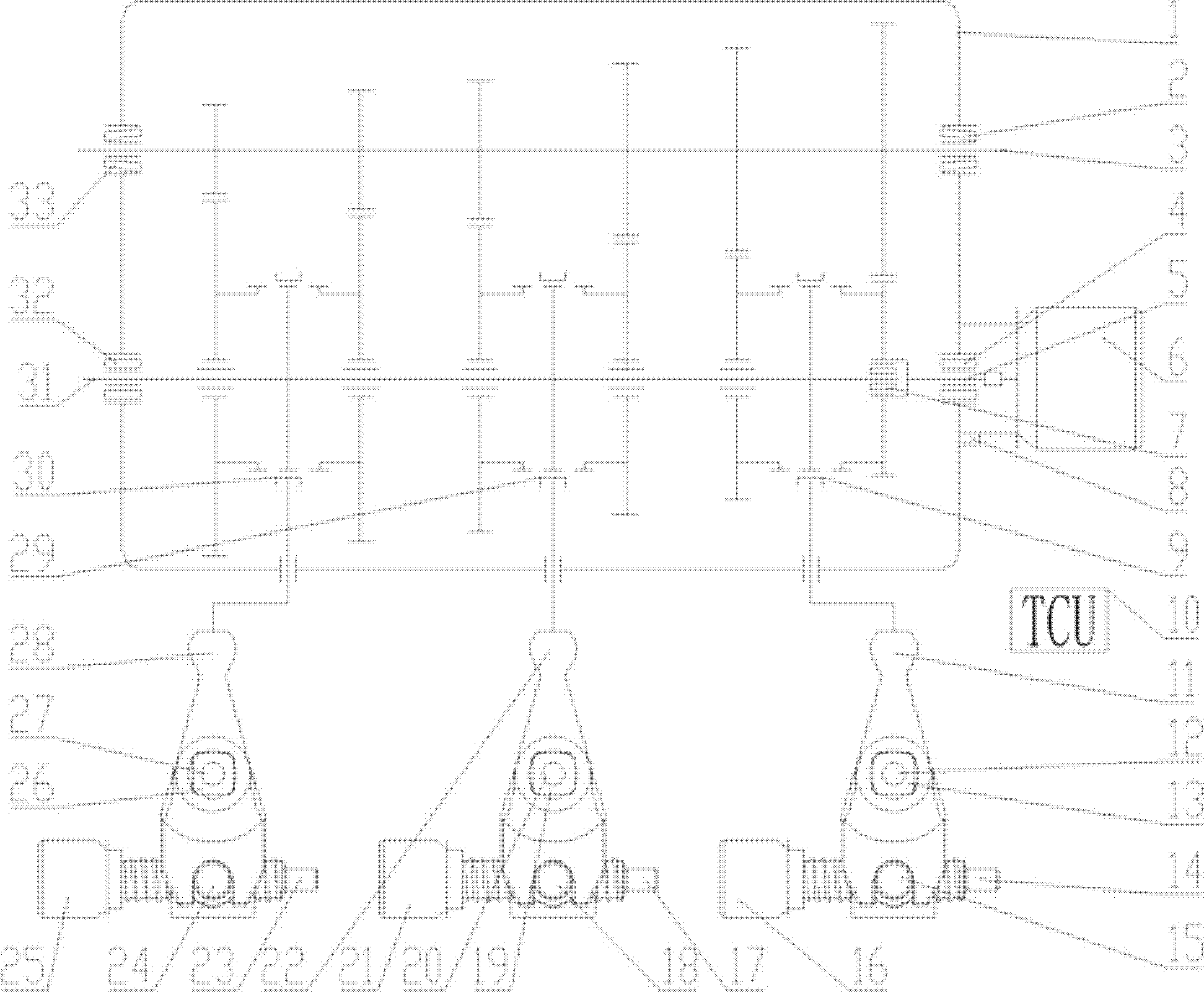

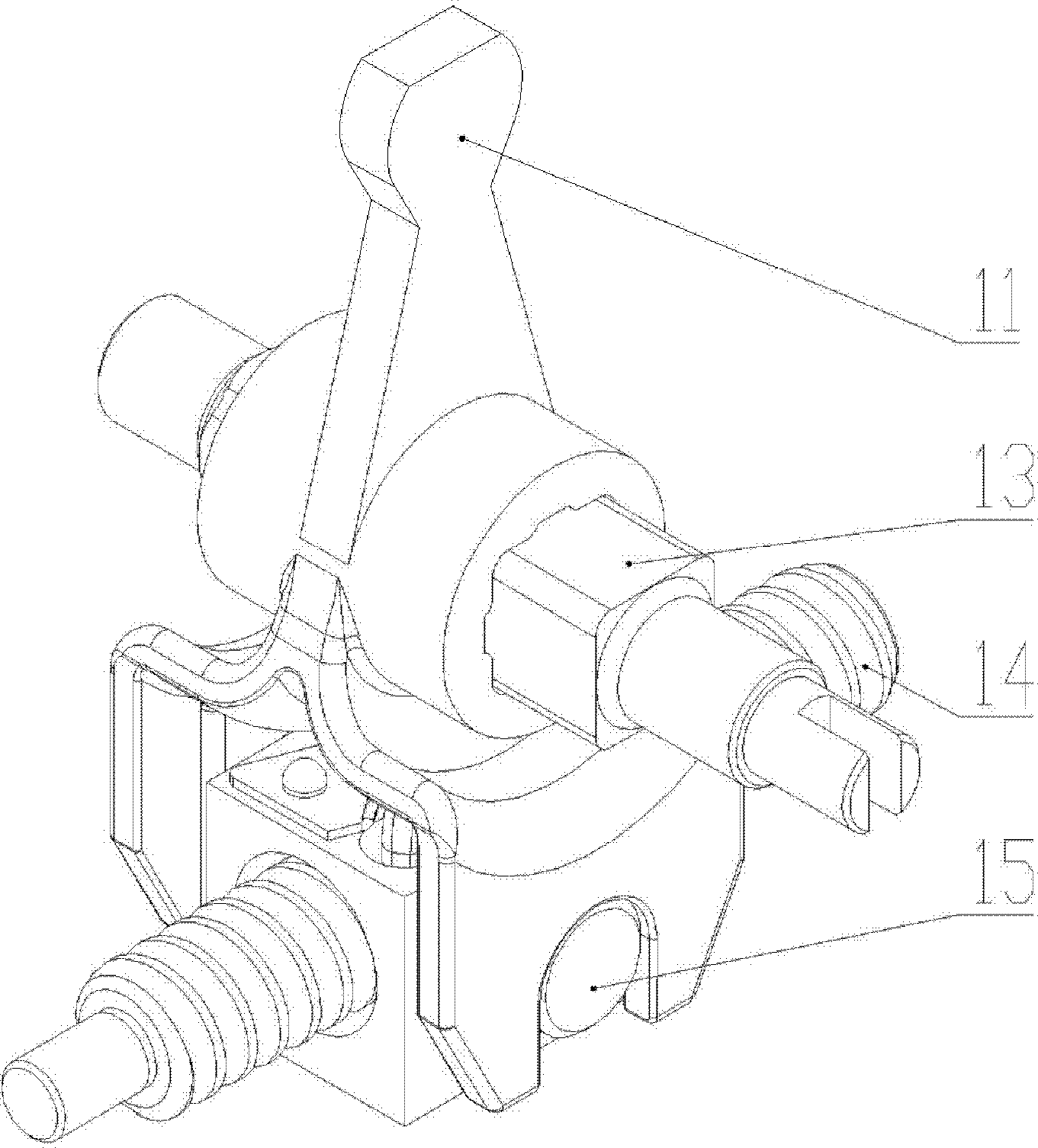

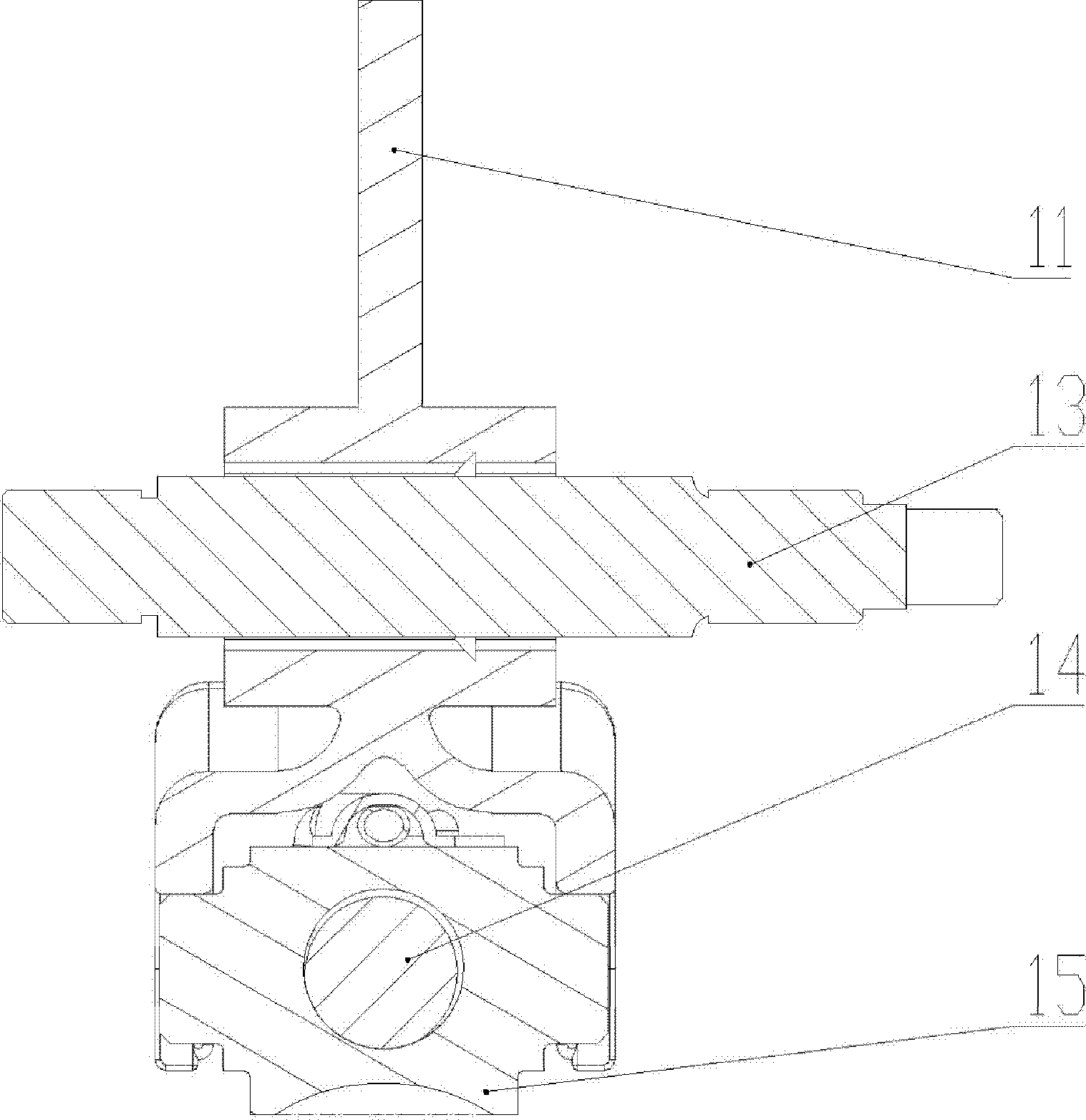

[0029] refer to figure 1 , The electronically controlled electric six-speed automatic shift system of the present invention is mainly composed of a parallel shaft gearbox 1 , a drive motor 6 , a shift mechanism and an electronic control unit (TCU) 10 .

[0030]The drive motor 6 is an asynchronous motor. In the embodiment of the present invention, the asynchronous motor model HD60-4 is adopted, and the drive motor 6 is fixedly connected to the right casing wall of the casing in the parallel shaft gearbox 1 by bolts through its end cover. , the right end of the gearbox input shaft 5 is connected to the left output end of the drive motor 6 output shaft through a spline pair, and the right end of the gearbox input shaft 5 (located on the left side of the spline pair) is installed through the No. 1 cylindrical roller bearing 4 The right box wall of the box in the parallel shaft ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com