Small-size oxygen measuring device based on porous material gas cell

A technology of porous materials and measurement devices, which is applied in measurement devices, analytical materials, color/spectral property measurement, etc., can solve the problems of difficulty in miniaturization of a single device and integration of multi-component and multi-point measurement systems, and achieves improved measurement response. Time, small size, and the effect of improving the degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

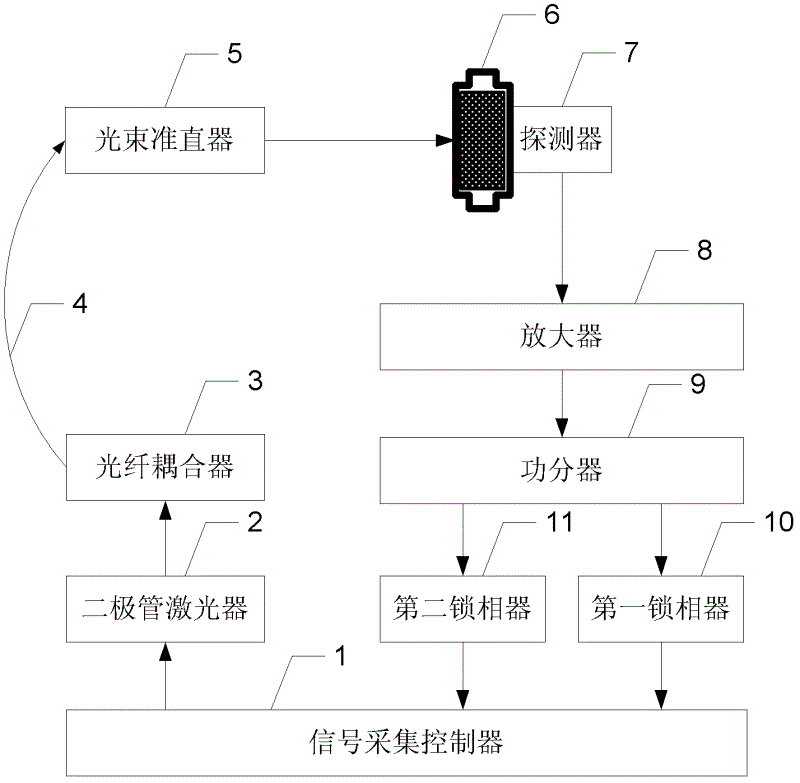

[0013] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the small oxygen measuring device based on the porous material gas cell described in this embodiment, it includes signal acquisition controller 1, diode laser 2, fiber coupler 3, optical fiber 4, beam collimator 5, porous material gas Pool 6, detector 7, amplifier 8, power splitter 9, first phase locker 10 and second phase locker 11,

[0014] The output end of the signal acquisition controller 1 is connected to the input end of the diode laser 2, the optical output end of the diode laser 2 is connected to the input end of the fiber coupler 3, the output end of the fiber coupler 3 is connected to the input end of the optical fiber 4, and the optical fiber The output end of 4 is connected to the input end of the beam collimator 5, and the output end of the beam collimator 5 emits a parallel laser beam incident on the porous material gas cell 6, and the laser beam passing through...

specific Embodiment approach 2

[0016] Embodiment 2: In this embodiment, Embodiment 1 is further described. The central wavelength of the light wave emitted by the diode laser 2 is within the range of 759 to 767 nm.

specific Embodiment approach 3

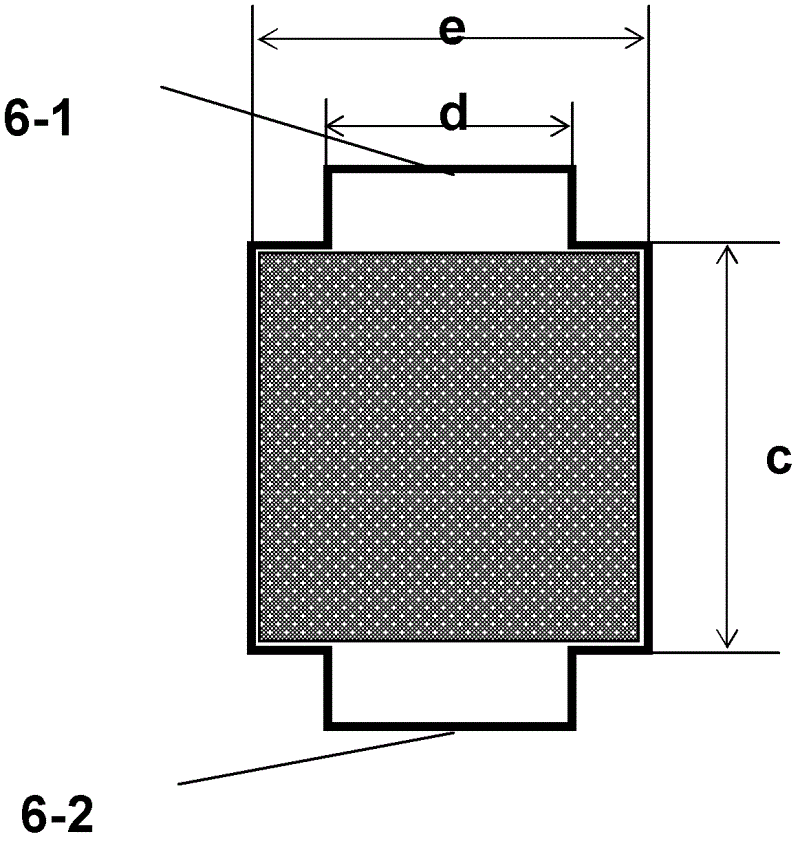

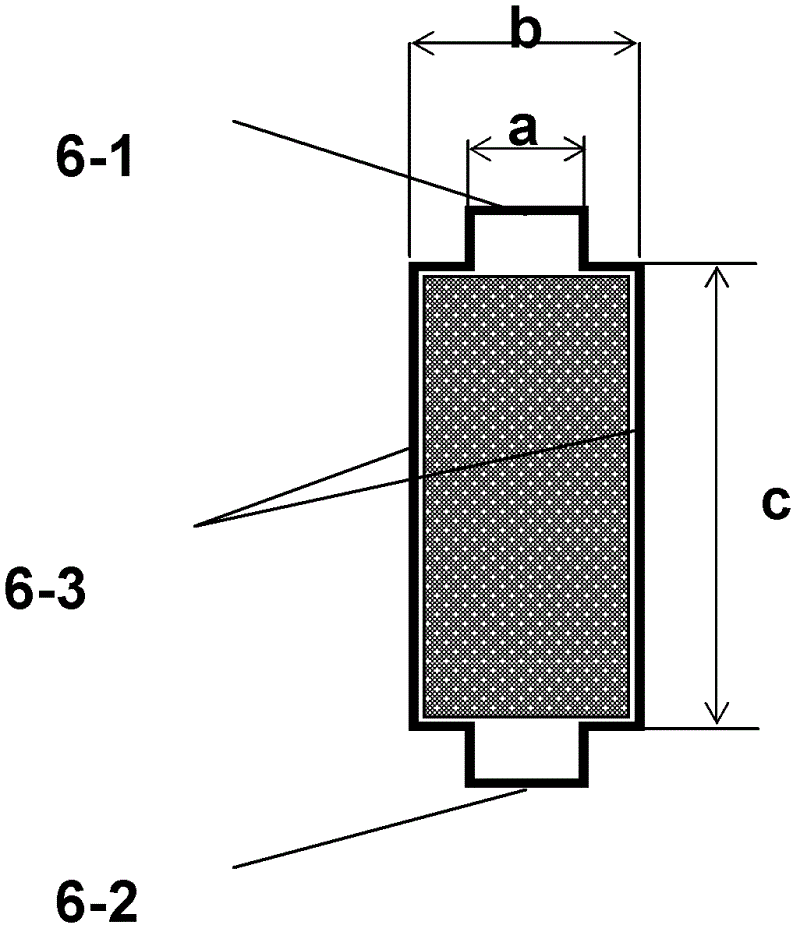

[0017] Specific implementation mode three: the following combination figure 2 of image 3 Describe this embodiment, this embodiment will further explain Embodiment 1, the porous material gas cell 6 has two end face windows 6-3, and the two end face windows 6-3 are parallel to each other, and the output of the beam collimator 5 The end emits a laser beam vertically;

[0018] The upper and lower ends of the porous material gas pool 6 are respectively provided with an air inlet 6-1 and an air outlet 6-2;

[0019] Fillers are provided inside the porous material gas pool 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com