High-precision ultrasonic range-measuring system

A distance measuring system, ultrasonic technology, applied in the direction of radio wave measurement system, sound wave reradiation, measuring device, etc., can solve the problem of failure to detect the return signal of obstacles, the self-excited oscillation of the amplifier circuit, the gain overflow of the signal amplifier circuit, etc. problems, to achieve the effect of improving the accuracy of short-distance measurement, expanding the use, and reducing the distance of blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

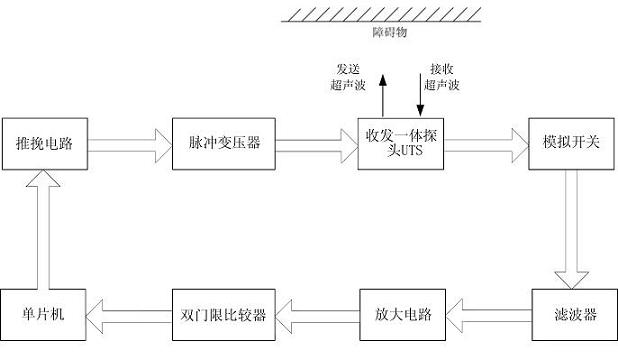

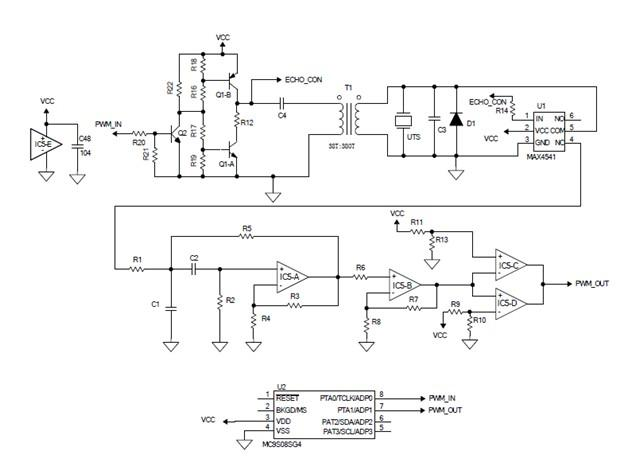

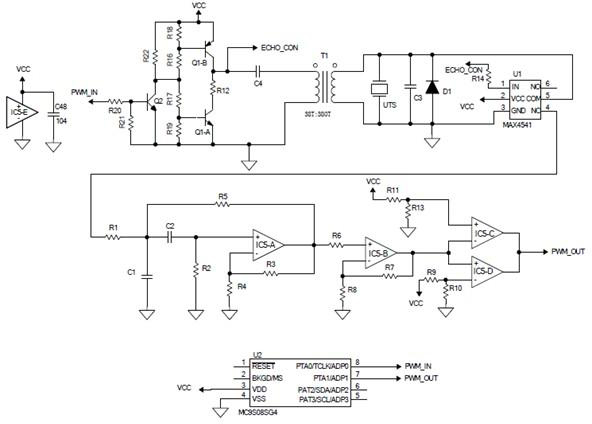

[0027] as attached figure 1 As shown, the ultrasonic ranging system circuit provided by the present invention mainly includes: a push-pull circuit, a pulse transformer T1, an ultrasonic probe UTS integrating transceiver, an analog switch U1, a band-pass filter, a secondary amplifier circuit, a dual-threshold comparator and a single-chip microcomputer, The push-pull circuit is connected to the pulse transformer T1, the output end of the pulse transformer T1 is connected to the ultrasonic probe, the output signal end of the ultrasonic probe is connected to the analog switch U1, the analog switch U1 is connected to the band-pass filter, and the band-pass filter is connected to the two A first-stage amplifying circuit, the second-stage amplifying circuit is connected to the double-threshold comparator, and the double-threshold comparator is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com