Permanent magnetic coupling transmission, braking or load device with cooling and lubricating device

A technology of permanent magnetic coupling and lubrication device, which is applied in the direction of permanent magnetic clutch/brake, cooling/ventilation device, electromechanical device, etc., and can solve the problem that the lubrication problem of permanent magnetic coupling components cannot be effectively solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

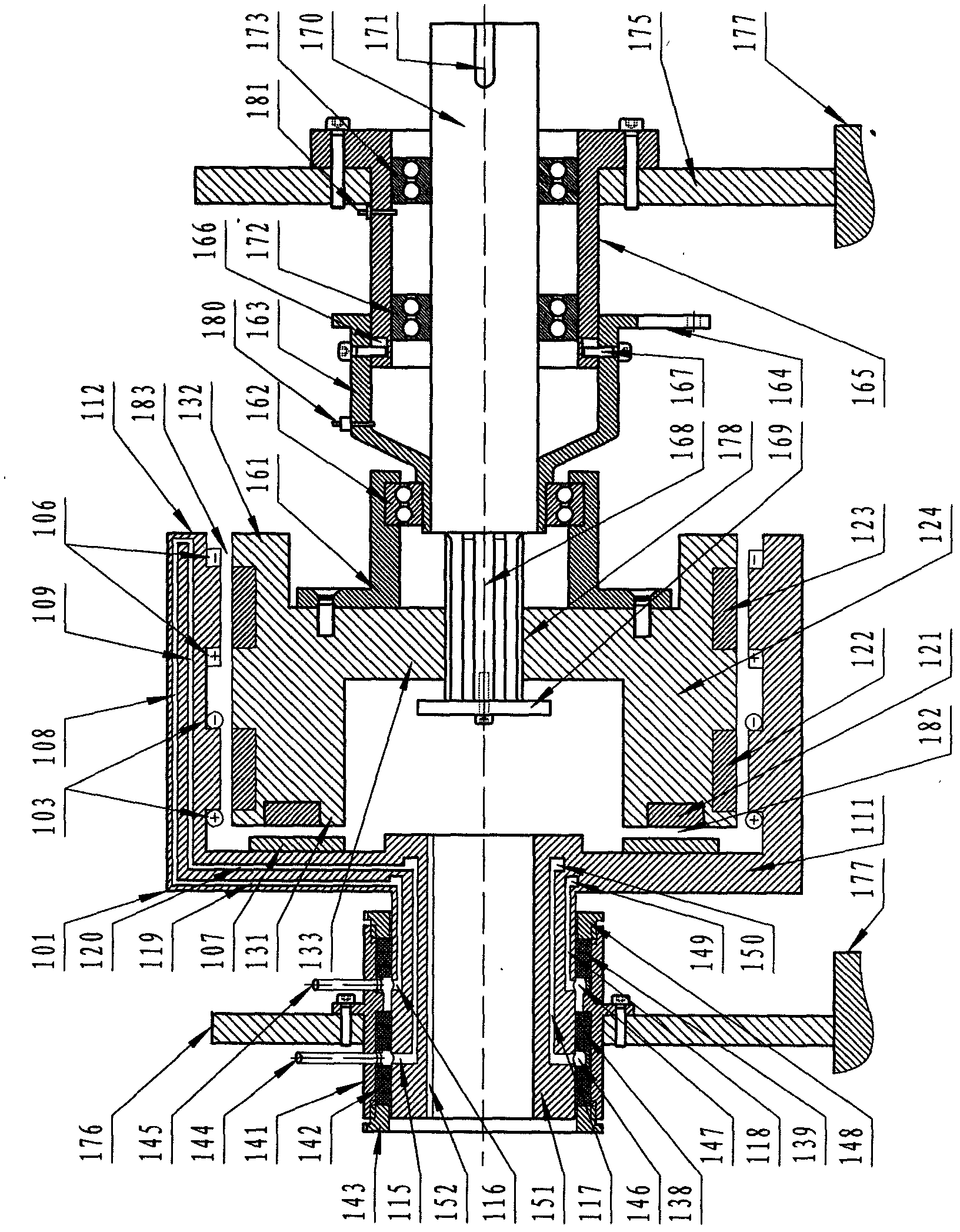

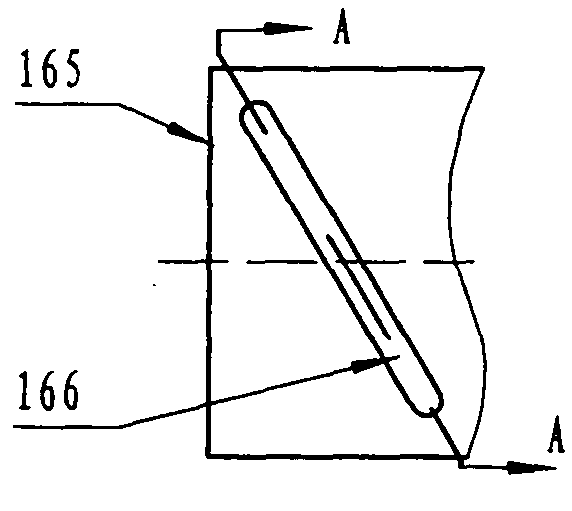

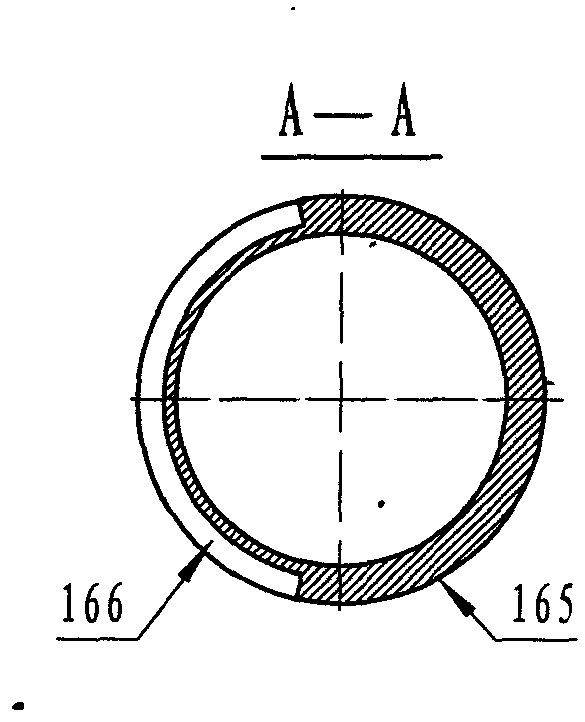

[0072] Such as figure 1 , figure 2 and image 3 As shown, it is "axial magnetic field + radial magnetic field + radial magnetic field" single-layer series-connected three sets of permanent magnetic coupling components. Magnetic field permanent magnetic coupling components (axial magnetic field circular metal conductor type permanent disk 107, axial magnetic field circular permanent magnetic disk 121) and two sets of radial magnetic field permanent magnetic coupling components (radial magnetic field cylindrical armature winding disk 103 , radial magnetic field cylindrical permanent disk 122, radial magnetic field cylindrical squirrel cage armature disk 106, radial magnetic field cylindrical permanent magnetic disk 123), a pair of active rotor disk (111) and rotating cylinder in the permanent magnetic coupling assembly (112) The matching active rotor disk coupling mechanism (151) and the corresponding driving shaft coupling mechanism (152), a pair of passive rotor disk (131) ...

Embodiment 2

[0077] Such as Figure 4 As shown, it is a "radial magnetic field + radial magnetic field" two-layer permanent magnetic coupling coupling with two sets of permanent magnetic coupling components nested drum structure, which consists of two sets of radial magnetic field permanent magnetic coupling components (one set is A permanent magnetic coupling assembly composed of a radial magnetic field cylindrical metal conductor armature disk 207 and a radial magnetic field cylindrical permanent disk 221. The cylindrical permanent disk 221 is nested with a metal conductor armature disk 203 and a radial magnetic field cylindrical permanent disk. 221 constitutes another set of permanent magnetic coupling assemblies), a pair of active drum coupling mechanisms (201, 211, 251) adapted to the active drums (212, 213) in the permanent magnetic coupling assembly and corresponding active Shaft coupling mechanism (253, 284, 276), a pair of passive drum coupling mechanism (passive drum body 233, sp...

Embodiment 3

[0081] Such as Figure 5As shown, it is a permanent magnetic coupling coupling of "radial magnetic field + radial magnetic field" two layers in series with four sets of permanent magnetic coupling components nested drum composite structure, consisting of four sets of radial magnetic field permanent magnetic coupling components ( The permanent magnetic coupling assembly composed of the radial magnetic field cylinder-type mouse dragon type armature disk 303 and the radial magnetic field cylindrical type permanent disk 322 is connected in series with the permanent magnetic coupling assembly composed of the mouse dragon type armature disk 306 and the permanent disk 323, embedded The permanent magnet coupling assembly that the winding armature disk 304 and the permanent magnetic disk 322 constitute are connected in series (the permanent magnetic coupling assembly composed of the winding armature disk 305 and the permanent magnetic disk 323), one pair and the driving drum (312, 302) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com