Palladium catalyst system comprising zwitterion and/or acid-functionalized ionic liquid

An ionic liquid, acid functionalization technology, used in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, catalytic reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

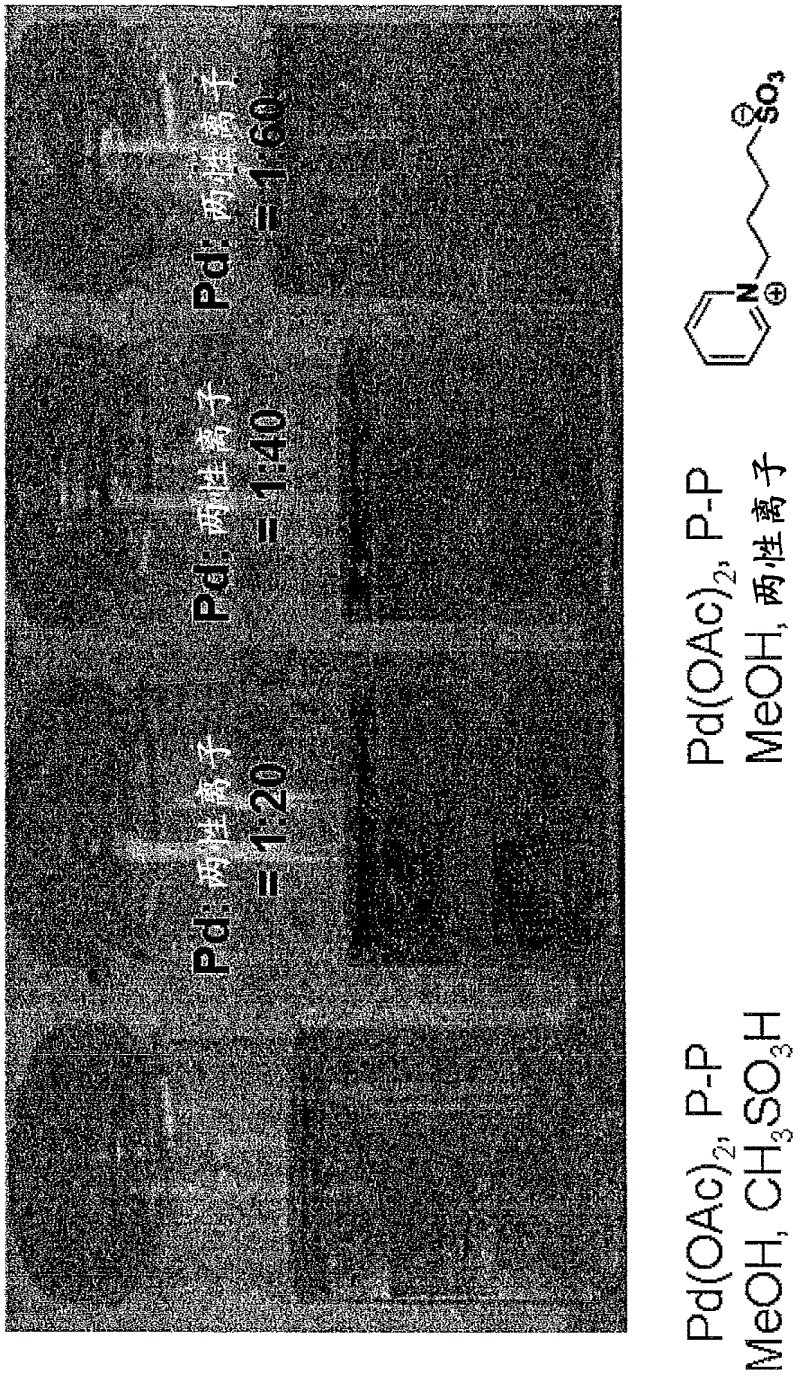

[0165] 1-(4-sulfonylbutyl)pyridine

[0166]

[0167] A mixture of pyridine (0.077 mol) and 1,4-butane sultone (0.07 mol) was heated with stirring at 70°C overnight. After completion, the resulting white solid was washed three times with 80 mL of diethyl ether. Finally, the product was dried under vacuum. The yield was 97.6%.

Embodiment 2

[0169] 1-(4-sulfonylbutyl)3-methylimidazole

[0170]

[0171] A mixture of 3-methylimidazole (0.099 mol) and 1,4-butane sultone (0.09 mol) was stirred and heated at 75°C for 2 hours. After completion, the resulting white solid was washed three times with 80 mL of diethyl ether. Finally, the product was dried under vacuum. The yield was 93.4%.

Embodiment 3

[0173] 1-(4-sulfonylbutyl)triethylammonium

[0174]

[0175] A mixture of triethylamine (0.077 mol) and 1,4-butane sultone (0.07 mol) was stirred and heated at 60° C. overnight. After completion, the resulting white solid was washed three times with 80 mL of diethyl ether. Finally, the product was dried under vacuum. The yield was 60.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com