Zinc amalgam particle and preparing process and usage thereof

A preparation process, a technology of zinc amalgam, applied in the field of zinc amalgam particles and its preparation, can solve the problems that amalgam is easy to generate mercury vapor, affect the purity of amalgam, pollute the production site, etc., and achieve the goal of eliminating secondary pollution and good processing capacity, and the effect of saving mercury sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

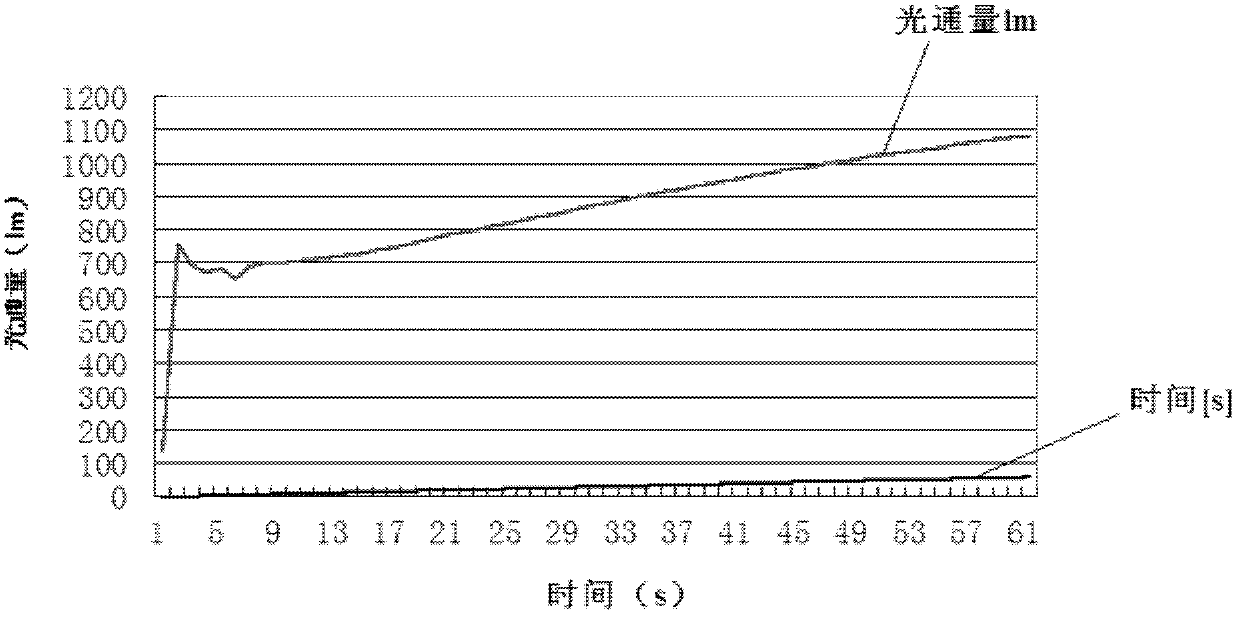

Image

Examples

Embodiment 1

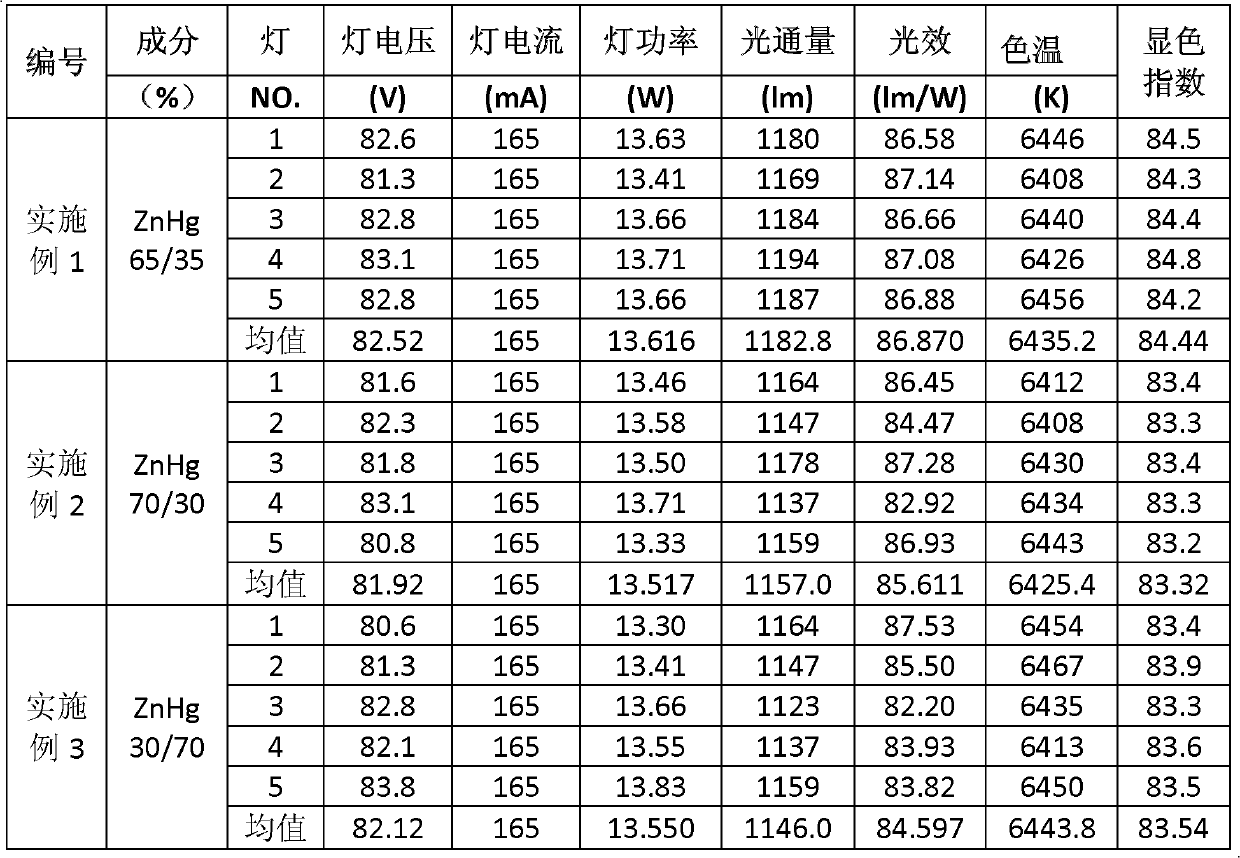

[0032] The zinc amalgam is formulated according to the mass ratio Zn:Hg=65:35 to produce 8 mg of zinc amalgam particles.

[0033] Accurately weigh 6.5kg of zinc flakes and 3.5kg of liquid mercury, and add them to a closed stainless steel container. The vessel was evacuated using a vacuum pump and then filled with argon inert gas. Melting was then performed by electric heating, and the temperature was set to 500°C. After the zinc and mercury in the container are completely melted, keep the internal temperature of the container at 450°C and the pressure at 20psi for 2 hours to make it fully mixed. Then by applying pressure, the pressure is controlled at 70psi, the alloy solution is pressed out, and alloy droplets (0.5-2.0mm in diameter) are formed through the vibrating nozzle, and the vibration frequency and amplitude are controlled at 600Hz and 0.3mm, respectively. Liquid nitrogen is passed into the hollow area between the inner tube and the outer tube in the double-layer cas...

Embodiment 2

[0035] The zinc amalgam is formulated according to the mass ratio Zn:Hg=70:30 to produce 25 mg of zinc amalgam particles.

[0036] Accurately weigh 7kg of zinc flakes and 3kg of liquid mercury, and add them to a closed stainless steel container. The vessel was evacuated using a vacuum pump and then filled with argon inert gas. Melting was then performed by electric heating, and the temperature was set to 500°C. After the zinc and mercury in the container are completely melted, keep the internal temperature of the container at 500°C and 30psi for 3 hours to make it fully mixed. Then by applying pressure, the pressure is controlled at 100psi, the alloy solution is pressed out, and alloy droplets (0.5-2.0mm in diameter) are formed through the vibrating nozzle, and the frequency and amplitude of the vibrating nozzle are controlled at 200Hz and 1mm, respectively. Liquid nitrogen is passed into the hollow area between the inner tube and the outer tube in the double-layer casing, a...

Embodiment 3

[0038] The zinc amalgam is formulated according to the mass ratio Zn:Hg=30:70 to produce 1 mg of zinc amalgam particles.

[0039]Accurately weigh 3kg of zinc flakes and 7kg of liquid mercury, and add them to a closed stainless steel container. The vessel was evacuated using a vacuum pump and then filled with argon inert gas. Melting was then performed by electric heating, and the temperature was set to 480°C. After the zinc and mercury in the container are completely melted, keep the internal temperature of the container at 480°C and 1 psi for 1 hour to make it fully mixed. Then by applying pressure, the pressure is controlled at 50psi, the alloy solution is pressed out, and alloy droplets (0.5-2.0mm in diameter) are formed through the vibrating nozzle, and the frequency and amplitude of the vibrating nozzle are controlled at 1000Hz and 0.1mm, respectively. Liquid nitrogen is passed into the hollow area between the inner tube and the outer tube in the double-layer casing, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com