Automatic tool changing system of manipulator

A technology of automatic tool change and manipulator, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of inapplicability of various machining centers, inapplicability of various spindles, mechanism damage, etc., and overcome the failure of loosening the tool Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

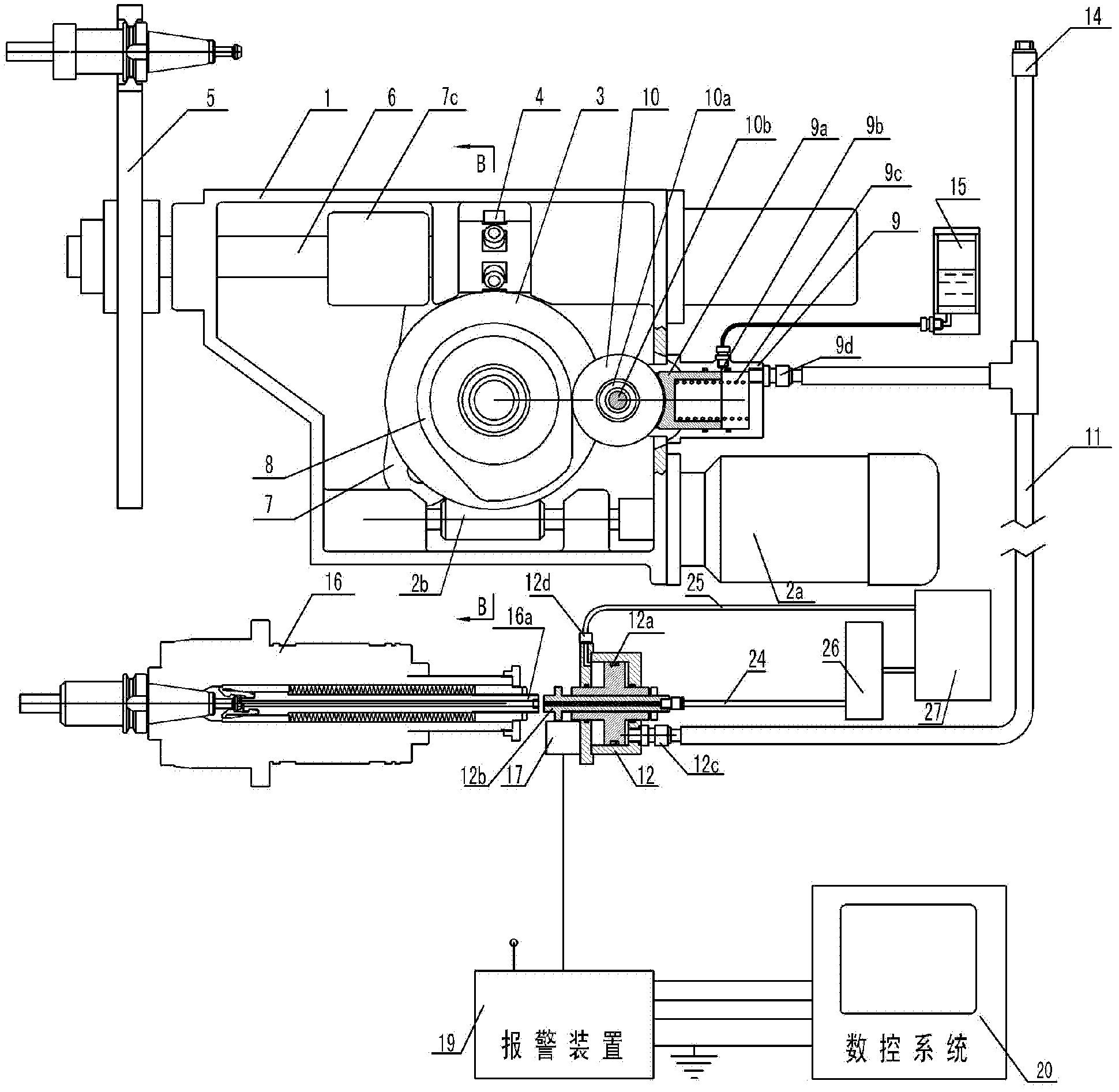

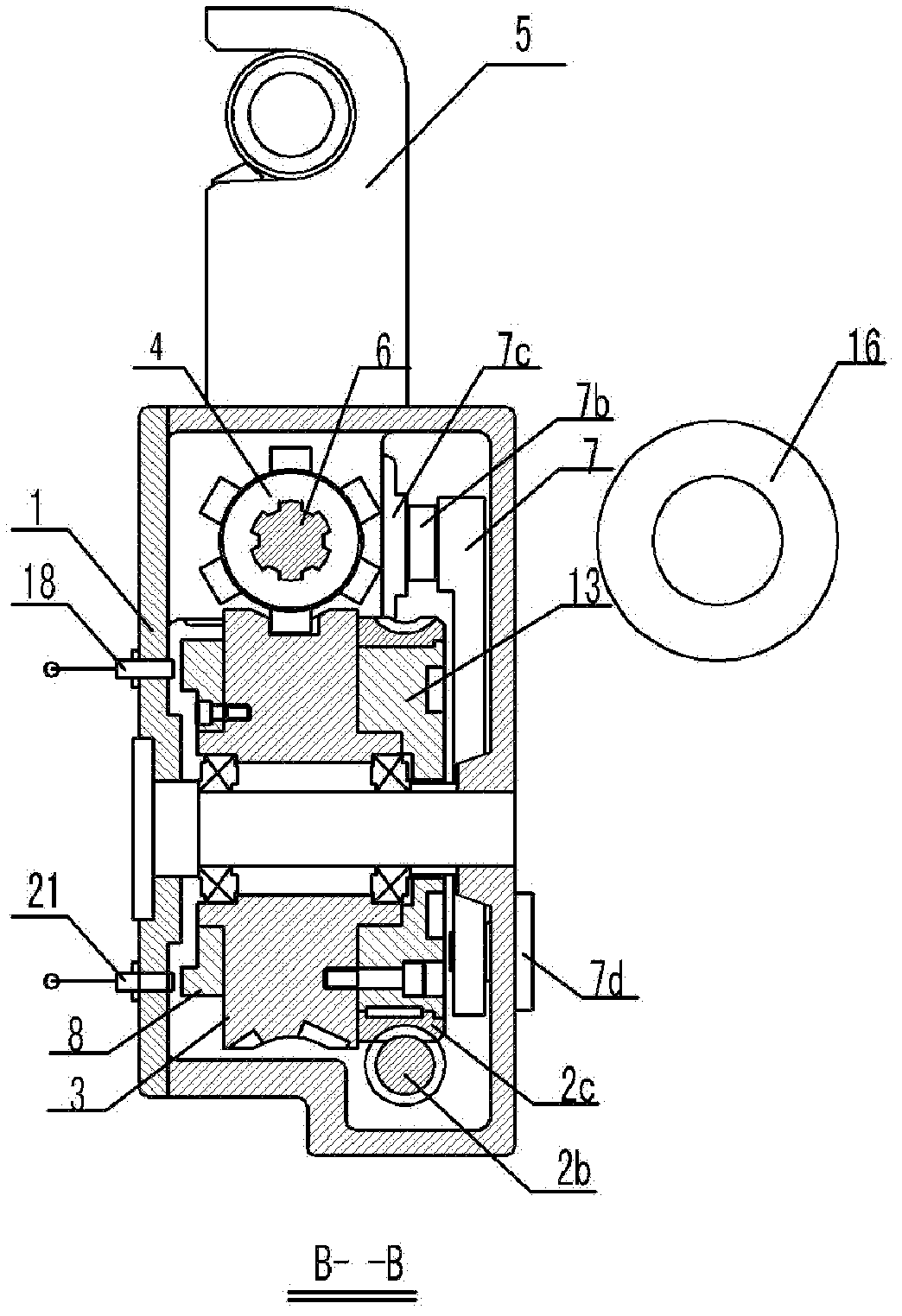

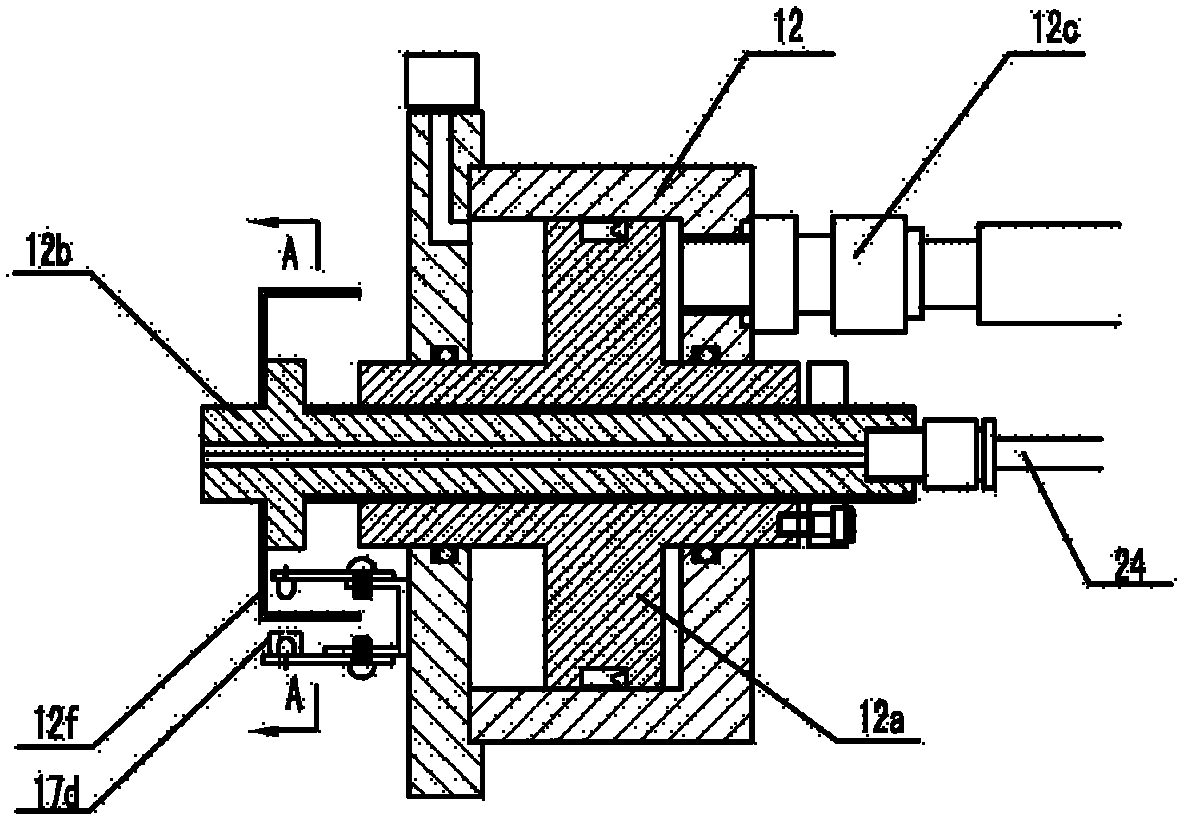

[0032] ginseng figure 1 , Figure 1a The manipulator automatic tool change system of the present invention consists of a housing 1, a brake motor 2a, a deceleration mechanism worm 2b, a deceleration mechanism worm gear 2c, a swing arm cam 3, a six-star wheel 4, a manipulator 5, a manipulator shaft 6, a knife insertion lever 7, Connecting rod 7b, bearing slider 7c, knife release cam 8, plunger oil pump 9, roller 10, high-pressure hose 11, knife release cylinder 12, knife release ejector rod 12b for adjusting the knife release stroke, with knife release rod 16a The main shaft 16, numerical control system 20, cam position switch 21 etc. constitute, the swing arm cam 3 is fixedly connected with the worm gear 2c of the reduction mechanism, and the annular cam groove on the outer circle of the swing arm cam 3 meshes with the six star wheel 4, and is made in or installed The inserting knife cam 13 on one side end face of the swing arm cam 3 meshes with the roller on the inserting kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com