Crosslinked polyethylene pyrrolidone-base fluorescent composite thin film and preparation method thereof

A polyvinylpyrrolidone-based and polyvinylpyrrolidone technology, which is applied in the field of fluorescent polymer film preparation, can solve the problems such as unreusable PVP and increase the use cost, so as to overcome the leakage of the fluorescent group, reduce the production cost, and increase the scope of the application field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

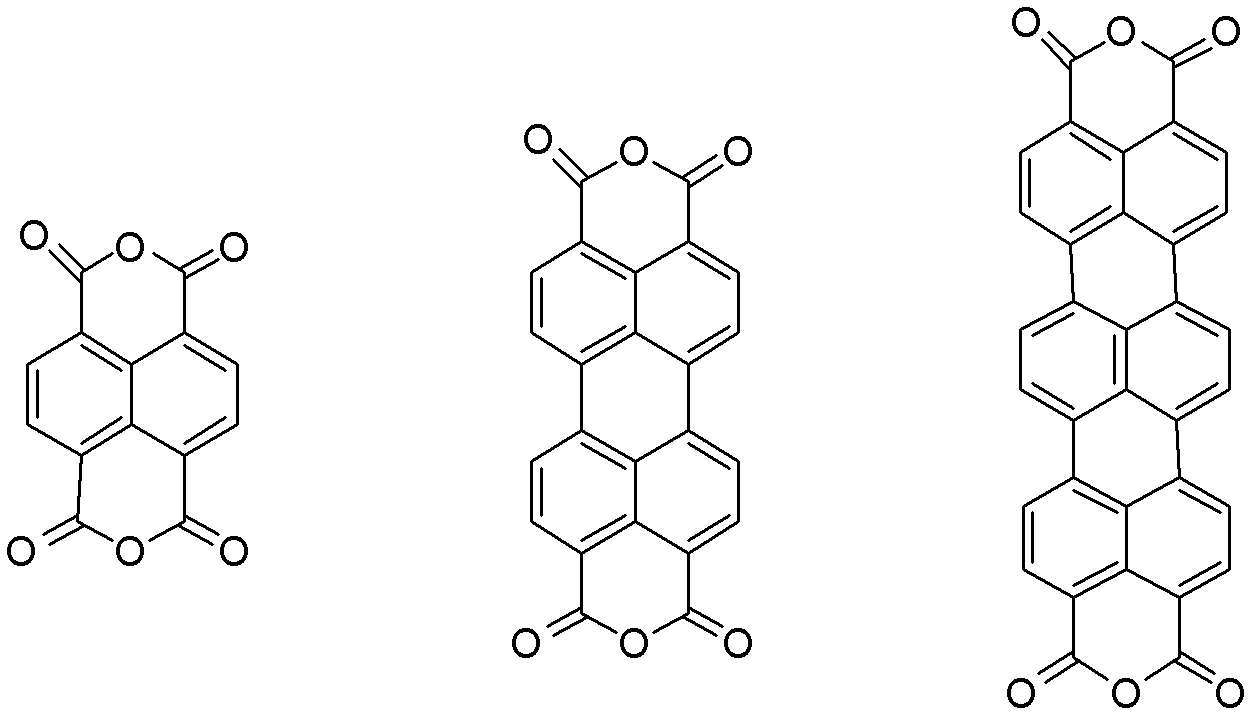

[0028] 1. Dissolve 0.03g of polyvinylpyrrolidone with a molecular weight of 40k-50k in 100ml of ethanol and acetone mixed solvent with a volume ratio of 0.1 under the condition of ice-water bath and mechanical stirring, the stirring speed is 800r / min, and the stirring time is 30min; Then stir at room temperature for 30 minutes; finally add 0.01 g of perylene anhydride under ultrasonic conditions, and continue ultrasonic dispersion for 30 minutes;

[0029] 2. Transfer the mixed solution prepared in step 1 to a high-pressure reactor, remove oxygen, and react at a temperature of 165°C for 30 hours;

[0030] 3. Cool to room temperature after the reaction, take out the film and wash it with ethanol and water three times, and then vacuum-dry it at 45°C for 24 hours to obtain a cross-linked polyvinylpyrrolidone-based fluorescent composite film.

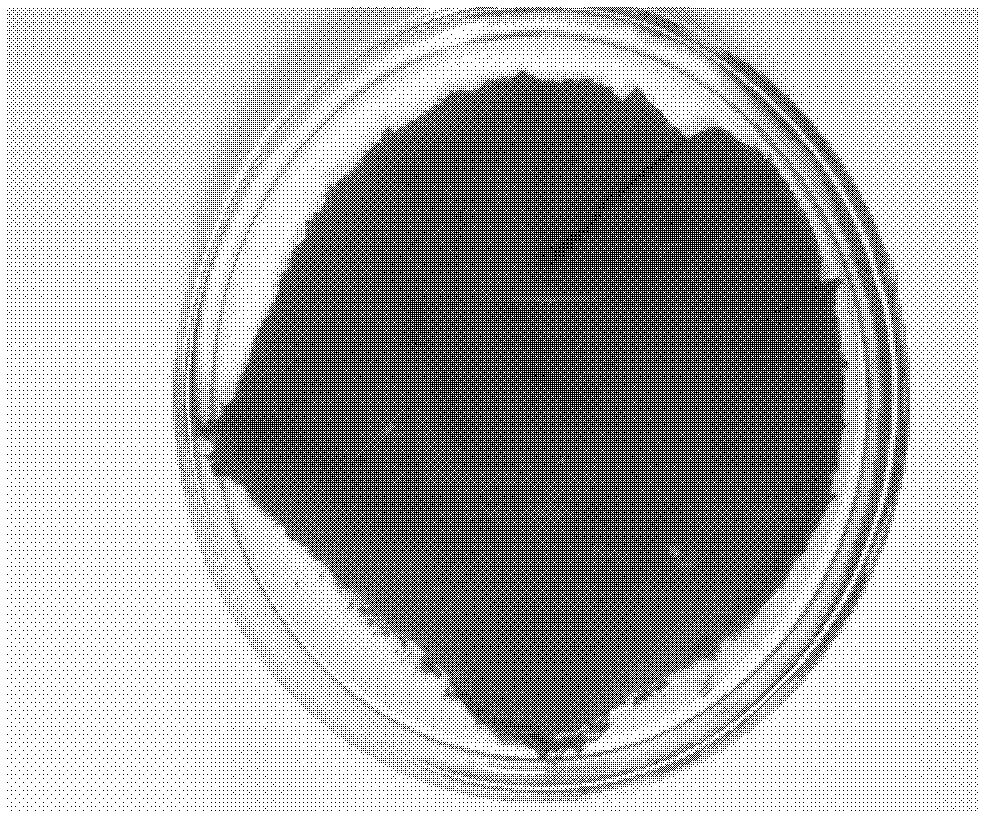

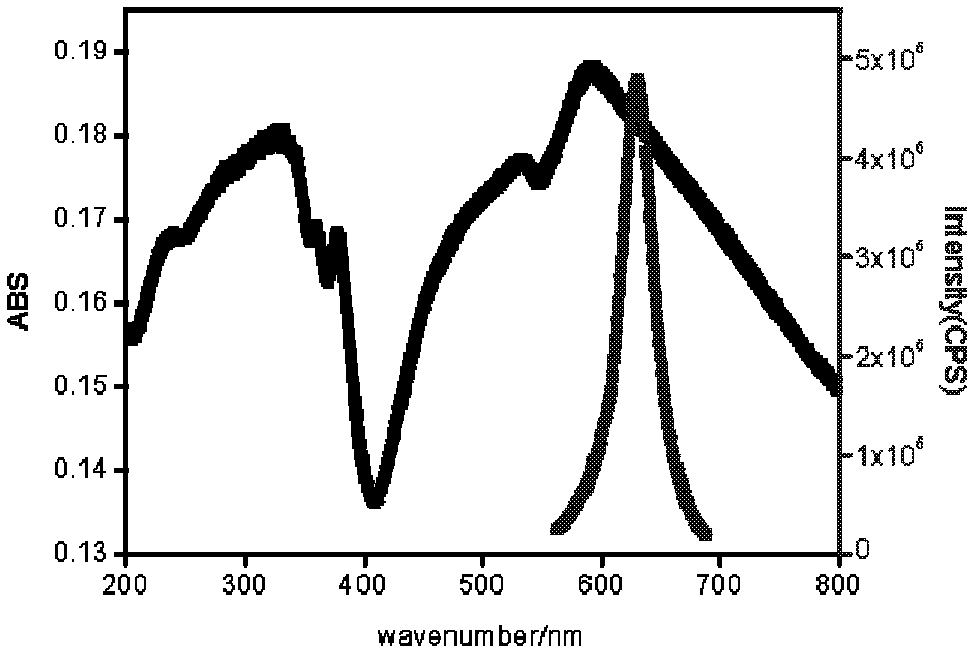

[0031] The cross-linked polyvinylpyrrolidone-based fluorescent composite film obtained in step (3) has a smooth surface, uniform color, sta...

Embodiment 2

[0033] 1. Dissolve 0.03g of polyvinylpyrrolidone with a molecular weight of 17k in a mixed solvent of ethanol and acetone with a volume ratio of 0.1 in 100ml under the conditions of ice-water bath and mechanical stirring, the stirring speed is 800r / min, and the stirring time is 30min; Stir at room temperature for 30 minutes; finally add 0.01 g of perylene anhydride under ultrasonic conditions, and continue ultrasonic dispersion for 30 minutes;

[0034] 2. Transfer the mixed solution prepared in step 1 to a high-pressure reactor, remove oxygen, and react at a temperature of 165°C for 30 hours;

[0035] 3. Cool to room temperature after the reaction, take out the film and wash it with ethanol and water three times, and then vacuum-dry it at 45°C for 24 hours to obtain a cross-linked polyvinylpyrrolidone-based fluorescent composite film.

[0036] The crosslinked polyvinylpyrrolidone-based fluorescent composite film obtained in the step (3) has smooth surface, uniform color and st...

Embodiment 3

[0038] 1. Dissolve 0.03g of polyvinylpyrrolidone with a molecular weight of 30k in a mixed solvent of ethanol and acetone with a volume ratio of 0.1 in 100ml under the conditions of ice-water bath and mechanical stirring, the stirring speed is 800r / min, and the stirring time is 30min; Stir at room temperature for 30 minutes; finally add 0.01 g of 4Cl-perylene anhydride under ultrasonic conditions, and continue ultrasonic dispersion for 30 minutes;

[0039] 2. Transfer the mixed solution prepared in step 1 to a high-pressure reactor, remove oxygen, and react at a temperature of 165°C for 30 hours;

[0040]3. Cool to room temperature after the reaction, take out the film and wash it with ethanol and water three times, then vacuum-dry it at 45°C for 24 hours to obtain a cross-linked polyvinylpyrrolidone-based fluorescent composite film.

[0041] The crosslinked polyvinylpyrrolidone-based fluorescent composite film obtained in the step (3) has smooth surface, uniform color and sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com