Mine drill stem

A mining and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of reducing the production efficiency of coal mine enterprises, inconvenient maintenance or replacement of drill pipe, and affecting the service life of drill pipe, etc., so as to reduce downtime Maintenance frequency, flexible loading and unloading, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific drawings and embodiments.

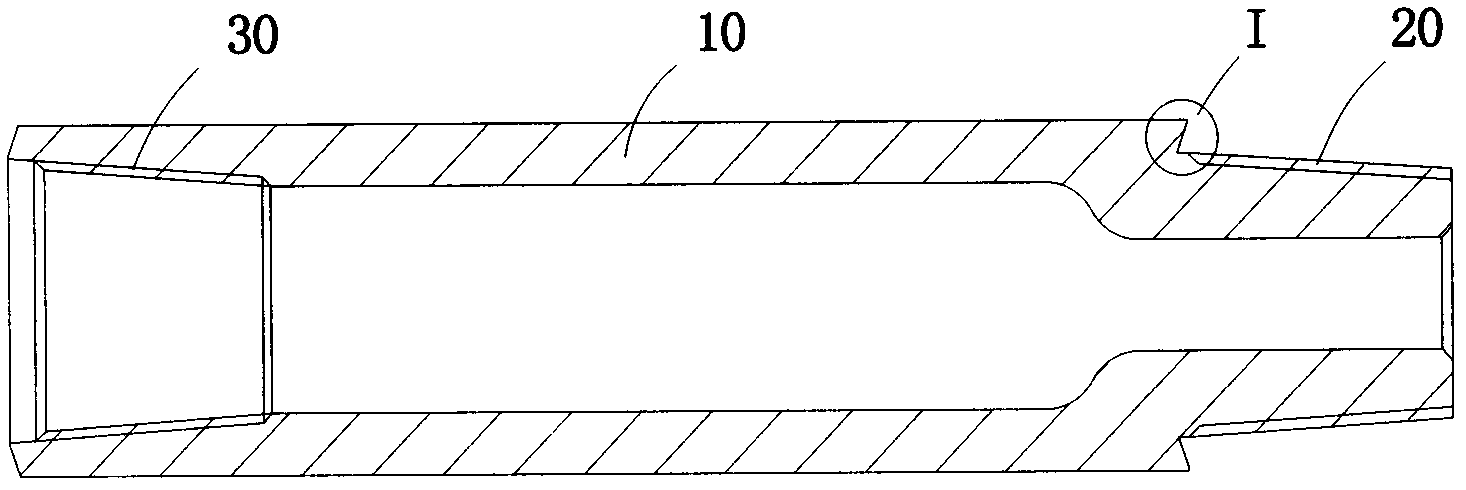

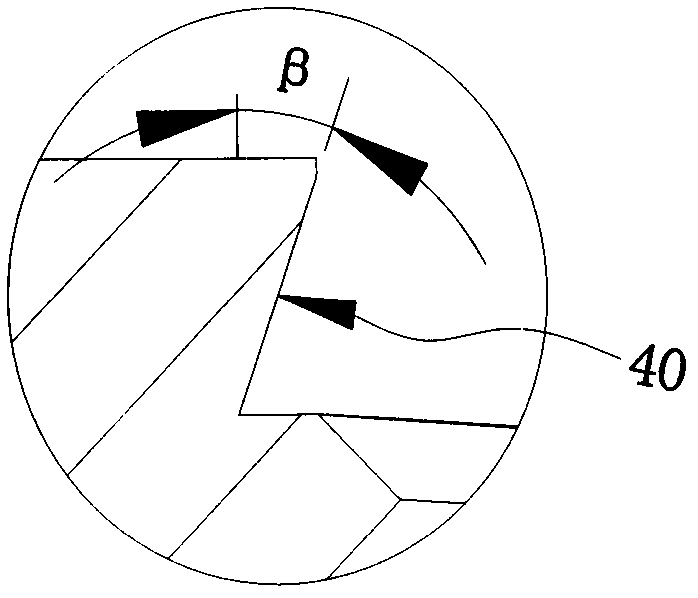

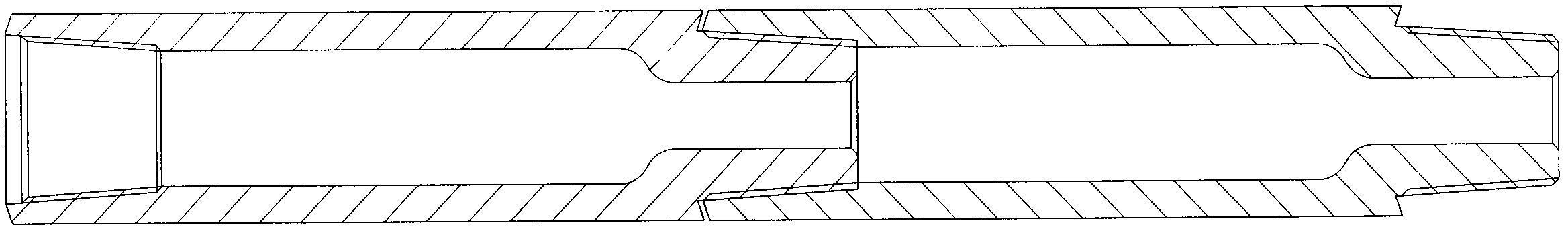

[0015] see figure 1 , a mining drill pipe assembly, comprising a hollow body 10, the two ends of the hollow body 10 are provided with an external tapered thread 20 and an internal tapered thread 30 that are matched with each other and undergone high-frequency quenching, and the external tapered thread 20 and the internal tapered thread 30 The joint surface 40 is a tapered surface.

[0016] Since the external taper thread 20 and the internal taper thread 30 at both ends of the hollow body 10 match each other, the drill rod components can be connected by the cooperation of the external taper thread 20 and the internal taper thread 30 to form a drilling rod for drilling. Each drill rod assembly The structure is simple, flexible in loading and unloading, and does not require welding. Users can connect to the length required for drilling according to needs, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com