Full-solid urase electrode and preparation method thereof

An all-solid-state, urease technology, applied in the field of electroanalytical chemical detection, can solve the problems of long time, high cost, need to add reagents, etc., and achieve the effects of fast response, low production cost, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation process and steps in this embodiment are as follows:

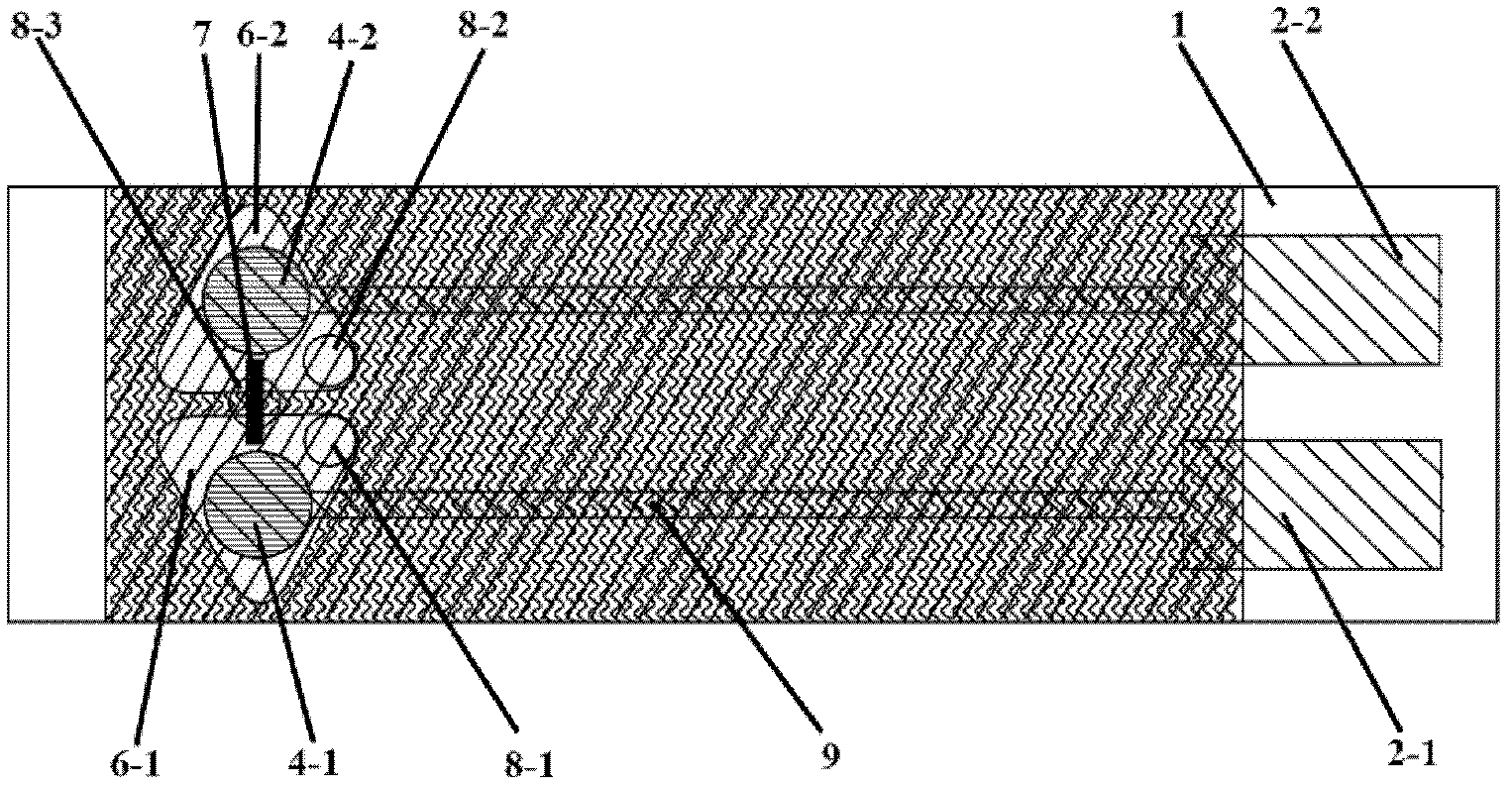

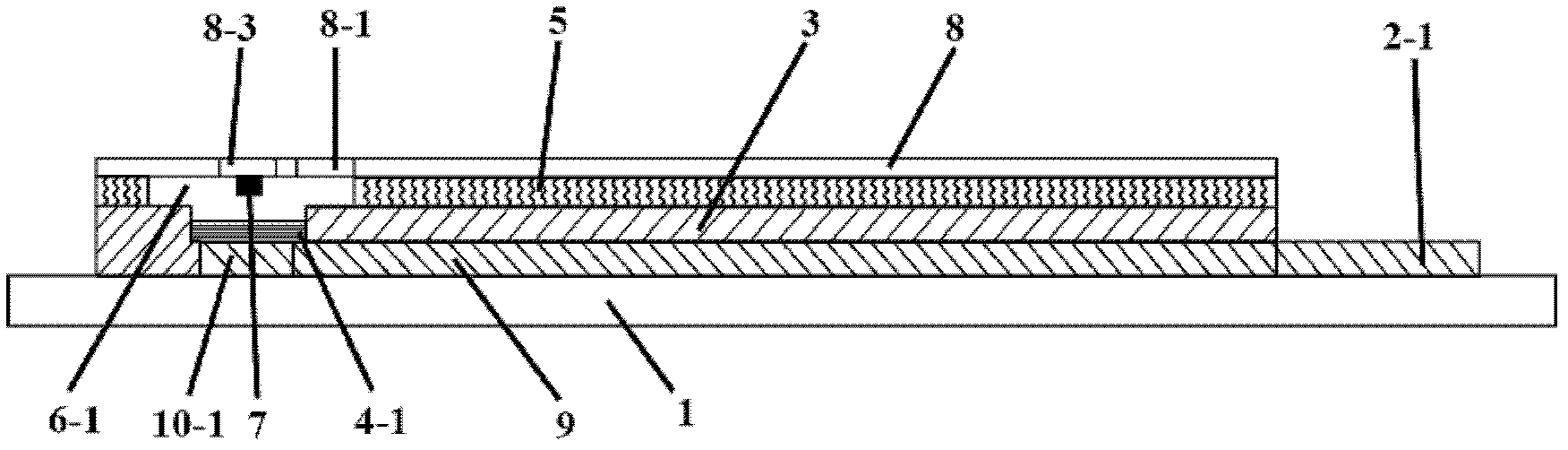

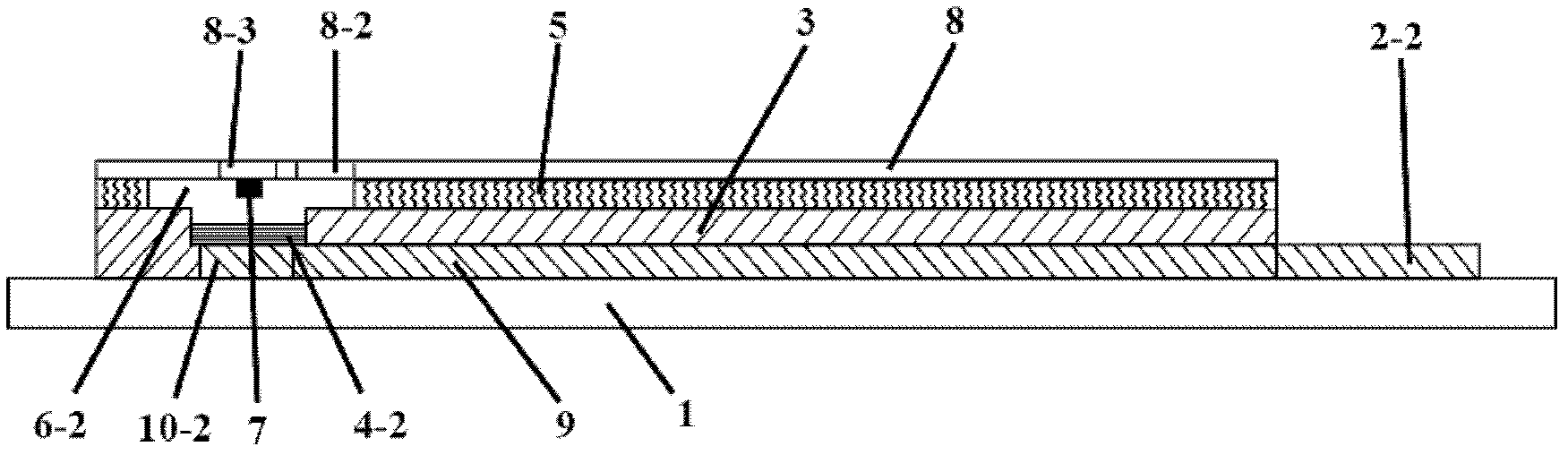

[0041] (1) Print a layer of silver paste on the polyvinyl chloride substrate by screen printing, and the silver paste layer is divided into the first contact electrode 2-1, the second contact electrode 2-2, the conductive layer 9, and the first reaction zone 10 -1 and the second reaction zone 10-2;

[0042] (2) Preparation of the reference electrode: the bovine serum albumin is formulated into an aqueous solution with a mass concentration of 5%; the nanometer MnO 2 Dispersed in carbon paste to form a mixture, nano MnO 2The mass concentration in carbon paste is 30%; Add the bovine serum albumin solution of mixture weight 12% in the mixture, be mixed with the second response layer slurry, print this response layer slurry with the method for screen printing, in the The second reaction area 10-2 prints the second response layer 4-2 so that it completely covers the second reaction area 10-2 and becomes ...

Embodiment 2

[0050] The preparation process and steps in this embodiment are as follows:

[0051] (1) Print a layer of silver paste on the polyvinyl chloride substrate by screen printing, and the silver paste layer is divided into the first contact electrode 2-1, the second contact electrode 2-2, the conductive layer 9, and the first reaction zone 10 -1 and the second reaction zone 10-2;

[0052] (2) Preparation of the reference electrode: the bovine serum albumin is prepared into an aqueous solution with a mass concentration of 5%; the nano-SnO 2 Dispersed in carbon paste to form a mixture, nano SnO 2 The mass concentration in carbon paste is 20%; Add the bovine serum albumin solution of mixture weight 7% in the mixture, prepare the second response layer slurry, print this response layer slurry with the method for screen printing, in the The second reaction area 10-2 prints the second response layer 4-2 so that it completely covers the second reaction area 10-2 and becomes a reference e...

Embodiment 3

[0060] The preparation process and steps in this embodiment are as follows:

[0061] (1) Print a layer of silver paste on the polyvinyl chloride substrate by screen printing, and the silver paste layer is divided into the first contact electrode 2-1, the second contact electrode 2-2, the conductive layer 9, and the first reaction zone 10 -1 and the second reaction zone 10-2;

[0062] (2) Preparation of reference electrode: bovine serum albumin is prepared into an aqueous solution with a mass concentration of 5%; 2 Dispersed in carbon paste to form a mixture, nano RuO 2 The mass concentration in carbon paste is 10%; Add the bovine serum albumin solution of mixture weight 2% in the mixture, prepare the second response layer slurry, print this response layer slurry with the method for screen printing, in the The second reaction area 10-2 prints the second response layer 4-2 so that it completely covers the second reaction area 10-2 and becomes a reference electrode, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com