Intelligent compensation system for geometrical and heating position errors of numerical control machine

A technology of CNC machine tools and compensation systems, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of inability to compensate for the real-time update of the model, weak robustness, etc., and achieve improved positioning accuracy and repeatable positioning accuracy. , improve the robustness, and solve the effect of precision compensation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited to the following embodiments.

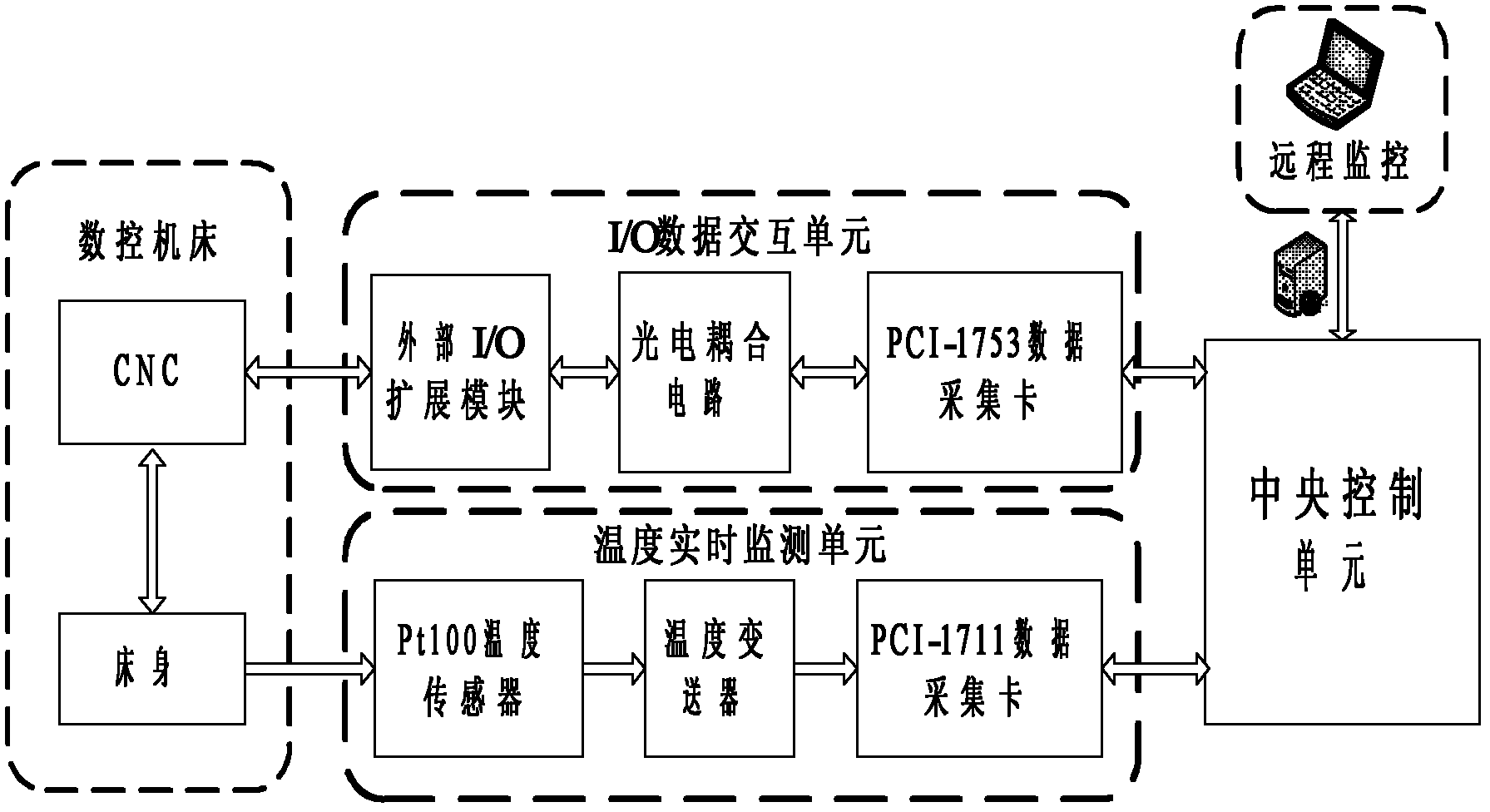

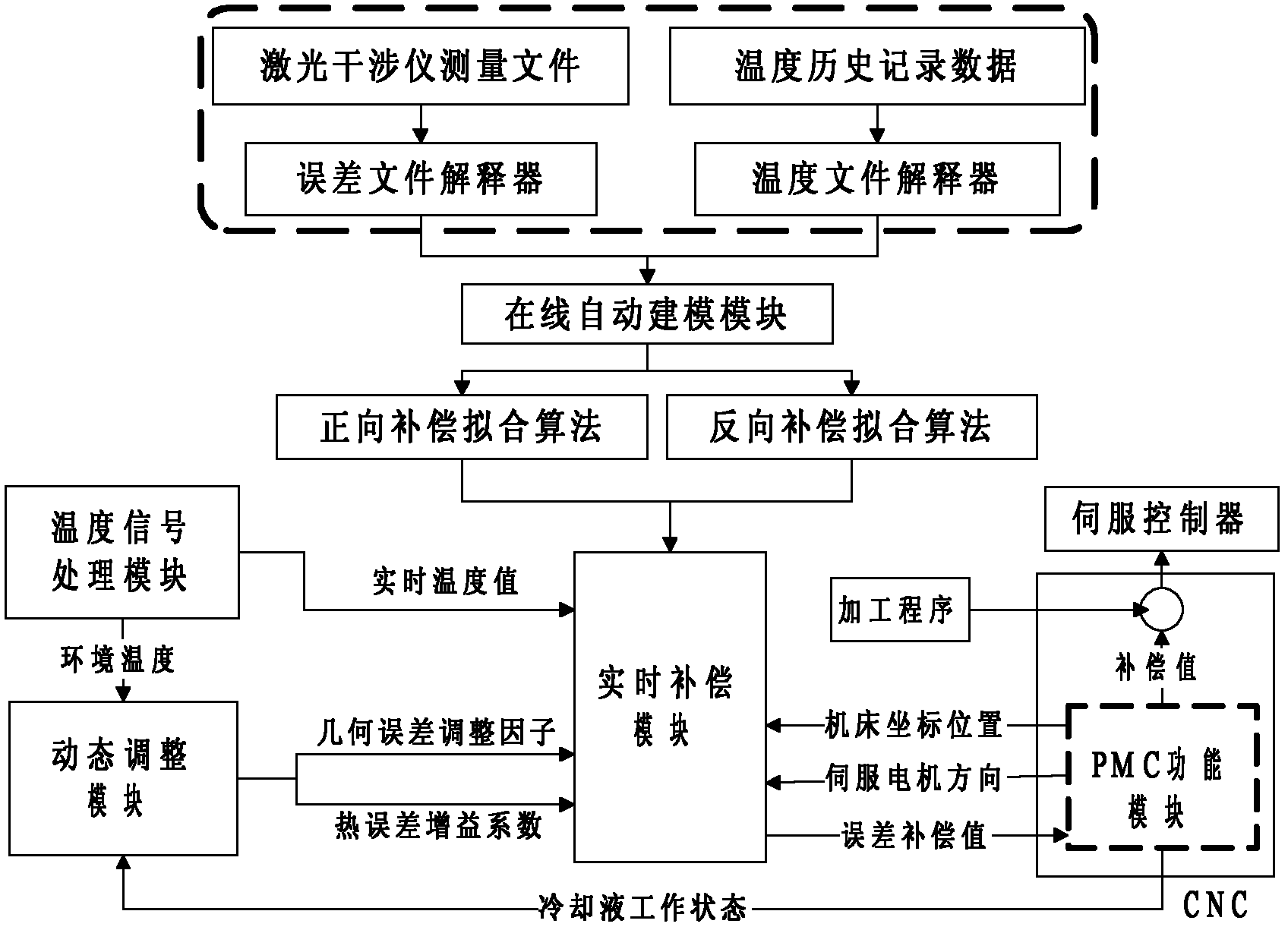

[0034]The present invention is developed based on the Labview platform, embedded industrial computer, and Advantech multifunctional data acquisition card. Based on the external origin offset function of the machine tool and the PMC window reading function of the numerical control system, it integrates a temperature monitoring unit, an I / O data interaction unit, An intelligent control platform integrating real-time compensation module, online automatic modeling module, dynamic adjustment module, machine tool performance analysis module and remote monitoring module.

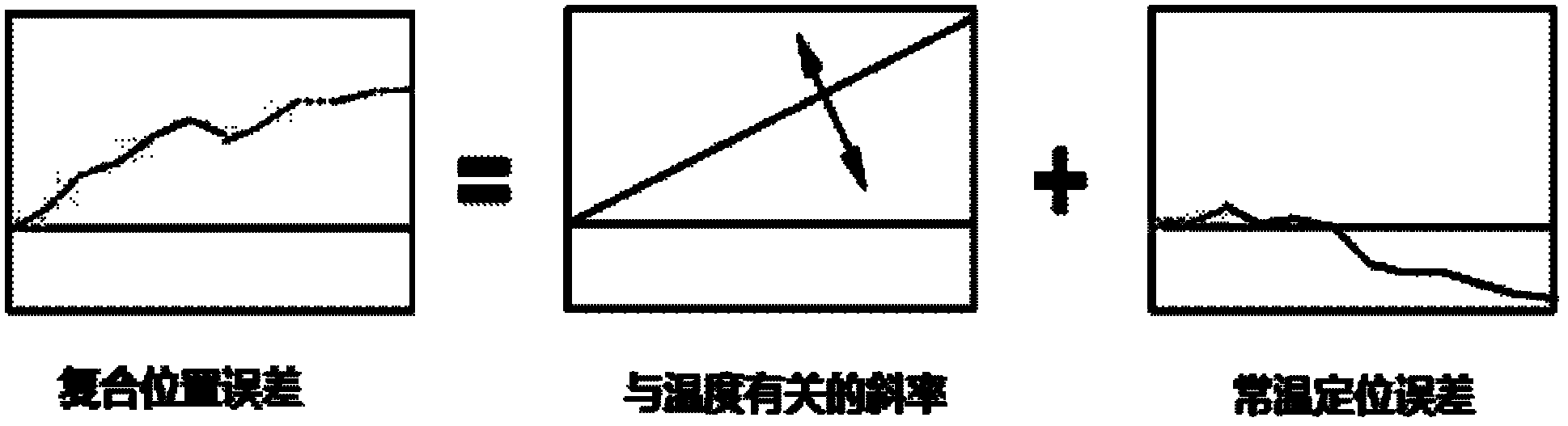

[0035] The intelligent compensation system for geometric and thermal composite position errors of CNC machine tools can monitor changes in external ambient temperature and processing conditions ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com