Closed-loop control LED (Light Emitting Diode) constant-current driving circuit

A technology of constant current drive and drive circuit, applied in electric lamp circuit arrangement, electric light source, lighting device, etc., can solve the problems of poor line regulation rate and load regulation rate, unstable working frequency, poor constant current effect, etc. Simple compensation, convenient application, and simple circuit implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

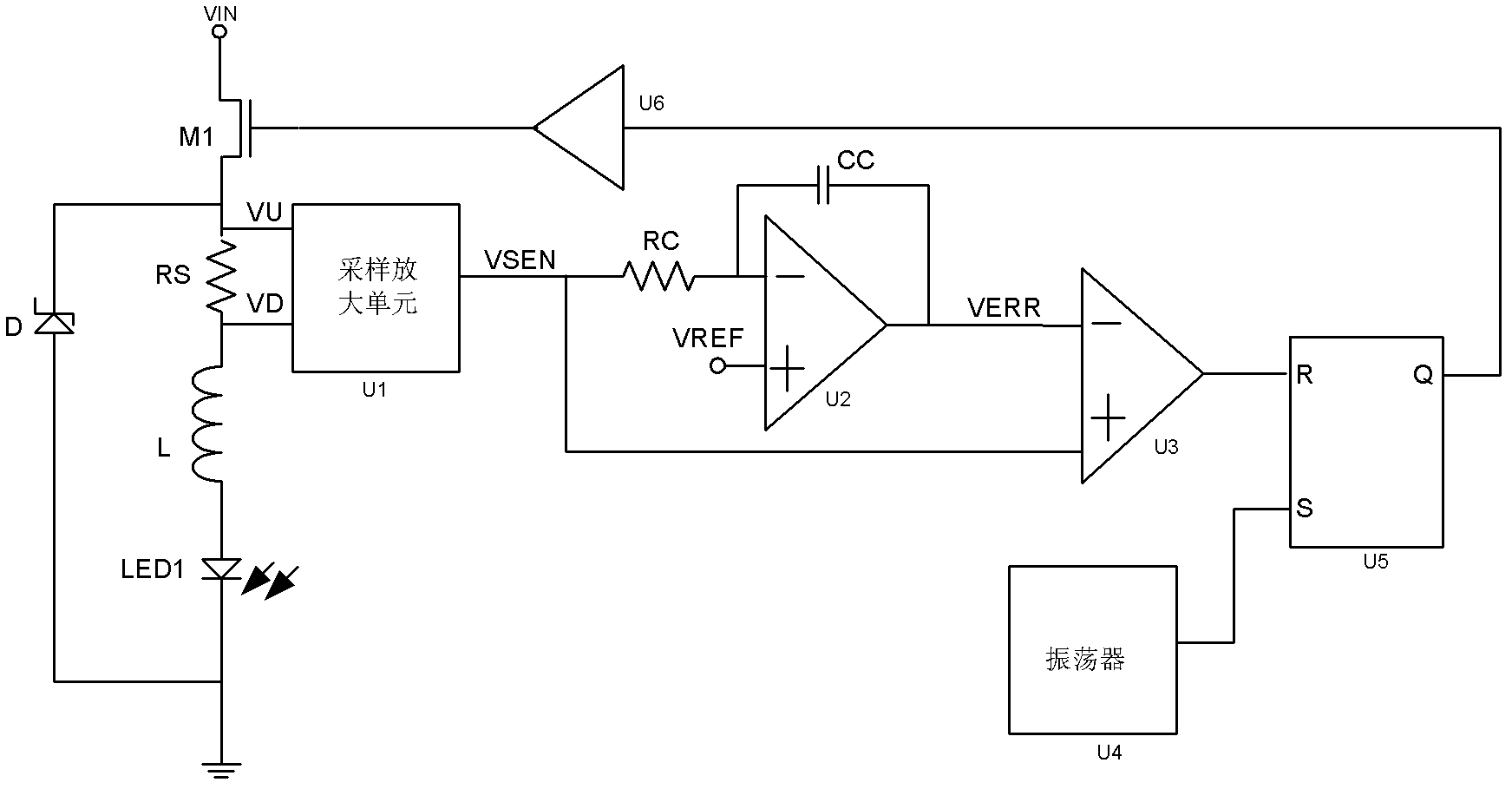

[0040] Such as image 3 As shown, the first embodiment of the LED constant current drive circuit with a fixed operating frequency proposed by the present invention includes a sampling amplifying unit U1, an error amplifier U2, a comparator U3, an oscillator U4, RS flip-flop U5 and power switch drive circuit U6. The output terminal of the power switch driving circuit U6 is electrically connected to the control terminal of the power switch M1. This embodiment also includes a frequency compensation unit composed of an inductor L, a freewheeling diode D, a compensation resistor RC and a compensation capacitor CC.

[0041] The typical operating waveform of the first embodiment is as Figure 4 Shown. Its working principle is: the sampling and amplifying unit U1 samples and amplifies the current information on the inductor L, and converts it into a voltage VSEN proportional to the inductor current. VSEN is compared with the reference voltage VREF, and the error amplifier outputs a vol...

no. 2 example

[0049] Such as Image 6 As shown, the second embodiment of the LED constant current drive circuit with a fixed operating frequency proposed by the present invention includes a sampling amplifying unit U1, an error amplifier U2, a comparator U3, an oscillator U4, RS flip-flop U5 and power switch drive circuit U6. The output terminal of the power switch driving circuit U6 is electrically connected to the control terminal of the power switch M1. This embodiment also includes a frequency compensation unit composed of an inductor L, a freewheeling diode D, a compensation resistor RC and a compensation capacitor CC. The difference from the first embodiment is that the power switch M1 is not located at the input power terminal VIN, but at the ground terminal.

[0050] Image 6 Implementation example of medium sampling amplification unit U1 Figure 7 Shown. Correct Figure 5 The simplification removes the current mirror circuit and only includes the operational amplifier I41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com