Formula and processing technology of black pepper beef flavoring bag

A processing technology, black pepper beef tenderloin technology, which is applied in the formula of black pepper beef tenderloin conditioning package and its processing technology, can solve the problems of not removing the smell of beef and the shape of the product, so as to achieve rich table, strong pepper flavor, The effect is soft, fresh and mellow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

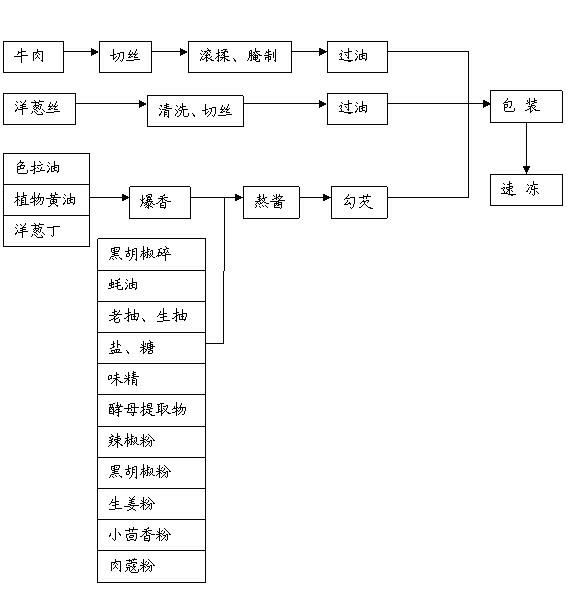

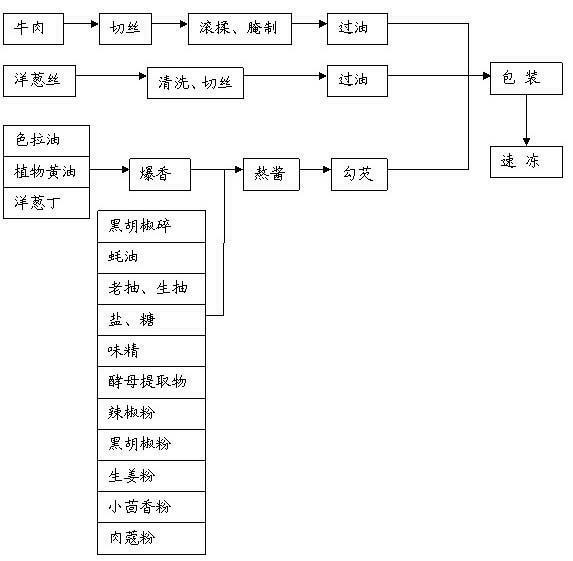

Method used

Image

Examples

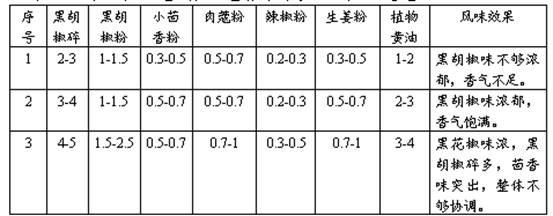

Embodiment 1

[0045]A recipe for black pepper beef tenderloin conditioning package, the raw materials and parts by weight in the recipe are: 98 parts of beef, 85 parts of water, 3.1 parts of egg liquid, 0.4 parts of baking soda, 0.45 parts of compound phosphate, 1.6 parts of black pepper powder 5 parts of sugar, 0.8 parts of salt, 2 parts of cornstarch, 20 parts of salad oil, 53 parts of shredded onion, 3 parts of diced onion, 3 parts of crushed black pepper, 6 parts of dark soy sauce, 3 parts of light soy sauce, 1 part of monosodium glutamate, 0.5 parts of yeast extract, 2 parts of vegetable butter, 2 parts of oyster sauce, 2 parts of modified starch, 0.5 parts of ginger powder, 0.5 parts of cumin powder, 0.5 parts of nutmeg powder, and 0.2 parts of chili powder.

[0046] According to the above formula, the black pepper beef tenderloin conditioning package is processed, and the processing technology comprises the following steps:

[0047] (1) Beef Tenderloin Processing Technology:

[0048...

Embodiment 2

[0074] A recipe for black pepper beef tenderloin conditioning package, the raw materials and parts by weight in the recipe are: 102 parts of beef, 90 parts of water, 3.3 parts of egg liquid, 0.45 parts of baking soda, 0.48 parts of compound phosphate, 2 parts of black pepper powder 4 parts of sugar, 0.9 parts of salt, 2.5 parts of cornstarch, 23 parts of salad oil, 58 parts of shredded onion, 3.5 parts of diced onion, 3.5 parts of crushed black pepper, 6.5 parts of dark soy sauce, 3.5 parts of light soy sauce, 1.5 parts of monosodium glutamate, 0.8 parts of yeast extract, 2.5 parts of vegetable butter, 2.5 parts of oyster sauce, 2.5 parts of modified starch, 0.6 parts of ginger powder, 0.6 parts of cumin powder, 0.6 parts of nutmeg powder, and 0.25 parts of chili powder.

[0075] According to the above formula, the black pepper beef tenderloin conditioning package is processed, and the processing technology includes the following steps:

[0076] (1) Beef Tenderloin Processing ...

Embodiment 3

[0103] A recipe for black pepper beef tenderloin conditioning package, the raw materials and parts by weight in the recipe are: 100 parts of beef, 85 parts of water, 3.1 parts of egg liquid, 0.45 parts of baking soda, 0.45 parts of compound phosphate, 2 parts of black pepper powder 5 parts of sugar, 0.8 parts of salt, 2 parts of cornstarch, 20 parts of salad oil, 53 parts of shredded onion, 3 parts of diced onion, 3 parts of crushed black pepper, 6 parts of dark soy sauce, 3 parts of light soy sauce, 1 part of monosodium glutamate, 0.5 parts of yeast extract, 2 parts of vegetable butter, 2 parts of oyster sauce, 2 parts of modified starch, 0.5 parts of ginger powder, 0.5 parts of cumin powder, 0.5 parts of nutmeg powder, and 0.2 parts of chili powder.

[0104] According to the above formula, the black pepper beef tenderloin conditioning package is processed, and the processing technology includes the following steps:

[0105] (1) Beef Tenderloin Processing Technology:

[0106...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com