Cement slurry pumping device

A technology of cement mortar and mud pump, which is applied to the device and coating of the surface coating liquid, which can solve the problems of high labor intensity, unsightly site environment, and low work efficiency, so as to reduce labor intensity and avoid site dirty Chaos, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

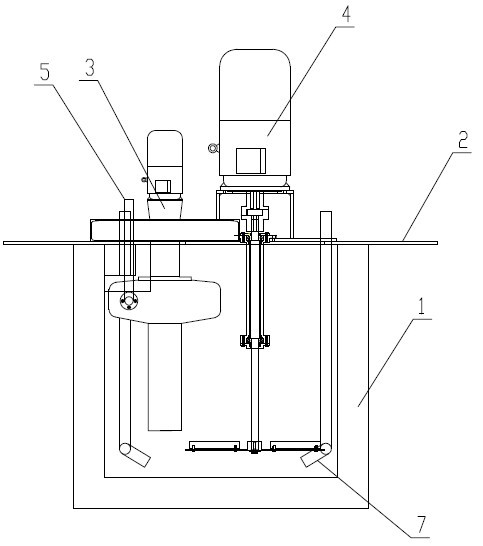

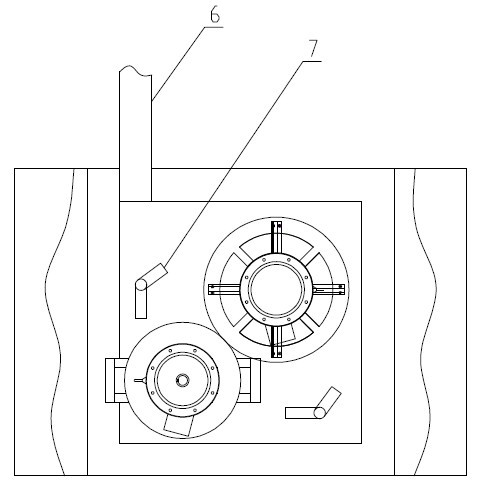

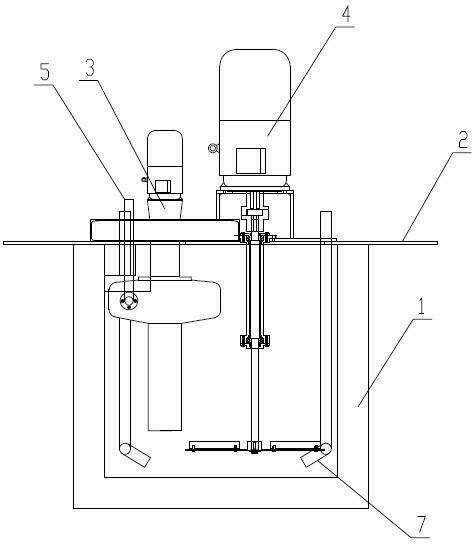

[0015] Such as figure 1 , figure 2 As can be seen from the shown embodiment, the cement mortar pumping device of the present invention includes a settling tank 1, a mud pump 3, an agitator 4, a power agitation device 7 and a PLC controller, and one side of the settling tank 1 is provided with The mortar inlet tank 6, the mud pump 3 is provided with a mortar outlet pipe 5; the input ends of the mud pump 3, the agitator 4 and the power agitation device 7 are respectively connected with the PLC controller through the motor, and the output ends pass through the The cover plate 2 of the sedimentation tank 1 extends into the slurry inside of the sedimentation tank 1 .

[0016] The power agitating device 7 includes a wind source, a ventilation pipe and a spray head, the input end of the ventilation pipe is connected to the wind source, and the output end is connected to the spray head.

[0017] One end of the mud pump outlet pipe 5 is connected with the output end of the mud pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com