Ball milling pot with agitation function for preparing micro-nano composite powder

A micro-nano composite and ball milling jar technology, applied in nanotechnology, grain processing and other directions, can solve the problems of poor composite effect of micro and nano powder, and achieve the effect of compact structure, strong practicability and high composite efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

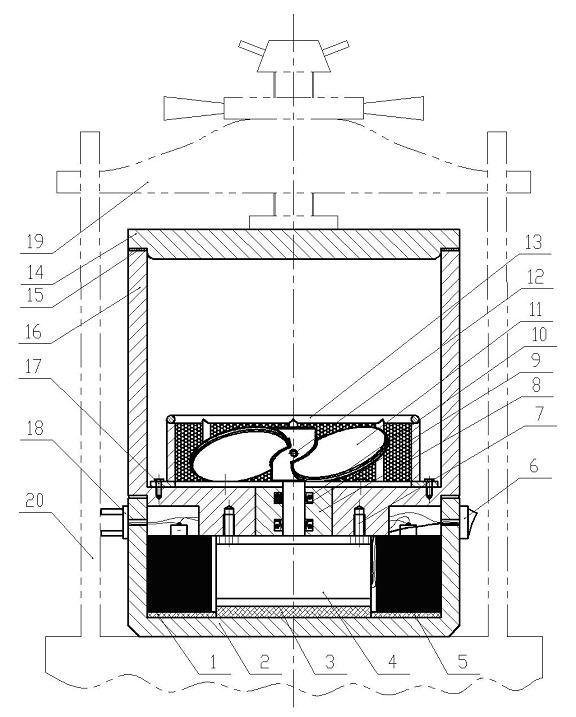

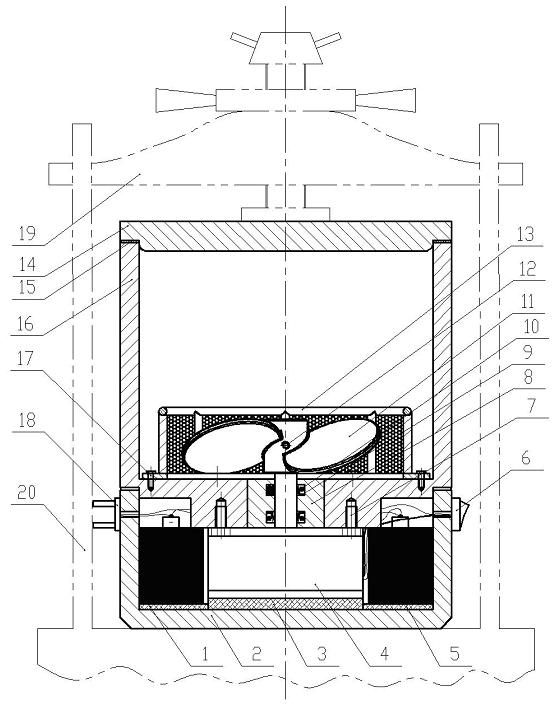

[0022] A ball mill tank with stirring function for preparing micro-nano composite powder, which includes a ring-shaped rubber pad 1, a bottom shell 2, a round rubber pad 3, a motor 4 (a small motor can be used), a battery 5 (a ring-shaped storage battery can be used) ), controllable power switch 6, fastening screw 7, sealing sleeve 8, L-shaped sealing ring 9, O-shaped sealing ring 10, stirring impeller 11, locking screw 12, impeller protective cover 13, ball mill tank end cover 14, seal Pad 15, ball milling pot shell 16, fastening screw 17, power supply charging interface 18, ball milling pot shell 16 and ball milling pot end cover 14 form a cavity for placing grinding balls and micro-nano composite powder, said The bottom of the ball milling tank housing 16 is installed on the base shell 2, and the inner bottom of the ball milling tank housing 16 is equipped with an impeller cover 13, and the top and surroundings of the impeller cover 13 can be covered with hollow wire mesh to...

Embodiment 2

[0027] Example 2: the micron powder is an Al-Si alloy powder with an average particle diameter of 50 μm, and the nanometer powder is Al with an average particle diameter of 20 nm 2 o 3 Ceramic powder; Al 2 o 3 The ceramic powder is placed in absolute ethanol to make a nano-suspension (appears as a white slurry), which is added to the ball milling tank of the present invention according to 2% of the mass fraction of the micron powder, and absolute ethanol is added to 2 / 3 of the ball milling tank, Set the ball milling parameters to carry out micro-nano powder compounding. After ball milling and compounding, the color of the upper white liquid medium in the ball mill tank is obviously lighter than that in Comparative Example 1. After the upper liquid medium is extracted and dried, the nanometer Al 2 o 3 The effective utilization rate of ceramic powder is about 72%. There is only a small amount of powder deposited at the bottom of the tank, and the deposited powder can be remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com