Preparation method for basic copper nitrate

A copper nitrate, basic technology, applied in directions such as copper nitrate, can solve the problems of unstable quality, poor product quality, high cost of basic copper nitrate, achieve good social and economic benefits, simple equipment and technological process, convenient The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

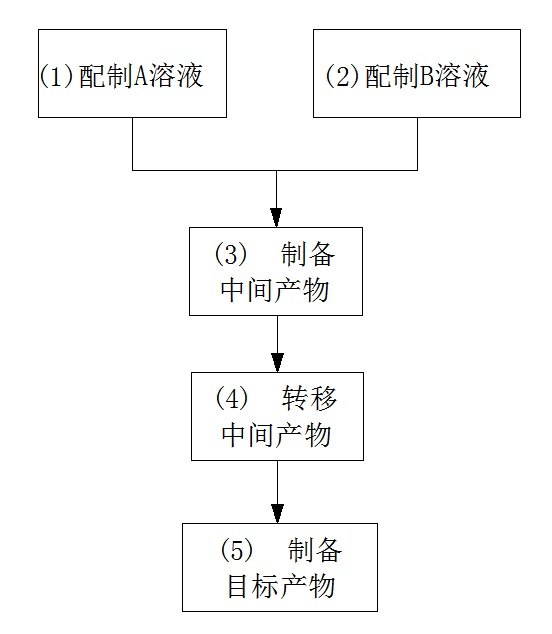

[0024] refer to figure 1 , the preparation method of basic copper nitrate of the present invention comprises the following steps:

[0025] (1), preparation of A solution: preparation containing Cu in the first reactor 2+ and NO 3 - A solution;

[0026] Specifically, solution A can be prepared directly by dissolving copper nitrate in water, or by reacting copper, copper hydroxide, basic copper carbonate, copper oxide, etc. with nitric acid. Here, there is no special requirement on the concentration of the A solution. As a preference, the Baume degree of the A solution is 5-55.

[0027] (2), preparation of B solution: preparation containing NH in the second reactor 4 + and OH - B solution;

[0028] Solution B can be ammonia water directly, or a mixed solution of ammonia water and water mixed in any proportion, or ammonia gas can be used directly, because the reaction process is carried out under water phase conditions, and ammonia gas is very soluble in water to form Am...

Embodiment 1

[0048] (1), prepare A solution: prepare the copper nitrate solution that Baumé degree is 5 in the first reactor, stand-by;

[0049] (2), preparation B solution: prepare NH in the second reactor 4 + Mass concentration is 1% ammonia solution, stand-by;

[0050] (3) Add 500L of water into the third reactor of 2000L, the water temperature is 10°C, then make the A solution and the B solution flow into the third reactor simultaneously and slowly to carry out the reaction process. During the reaction process, a pH meter is used to monitor the pH value of the solution in the third reactor in real time and determine whether to adjust the flow of the two solutions according to the situation, so that the pH value in the reactor is controlled at about 3. After a period of continuous reaction, the two solutions are closed to obtain an intermediate product;

[0051] (4), transfer the intermediate product: transfer the intermediate product to the fourth reactor, and wash until the washing...

Embodiment 2

[0054] (1), prepare A solution: prepare the copper nitrate solution that Baumé degree is 25 in the first reactor, stand-by;

[0055] (2), preparation B solution: prepare NH in the second reactor 4 + Mass concentration is 10% ammonia solution, stand-by;

[0056] (3) Preparation of intermediate product: Add 500L of water to the third reactor of 2000L, heat to 40°C, then flow the two solutions prepared in step (1) and step (2) into the third reactor simultaneously and slowly , carry out the reaction process. During the reaction process, a pH meter is used to monitor the pH value of the solution in the third reactor in real time and determine whether to adjust the flow of the two solutions according to the situation, so that the pH value in the reactor is controlled at about 6. After a period of continuous reaction, the two solutions are closed to obtain an intermediate product;

[0057] (4), transfer the intermediate product: transfer the intermediate product to the fourth re...

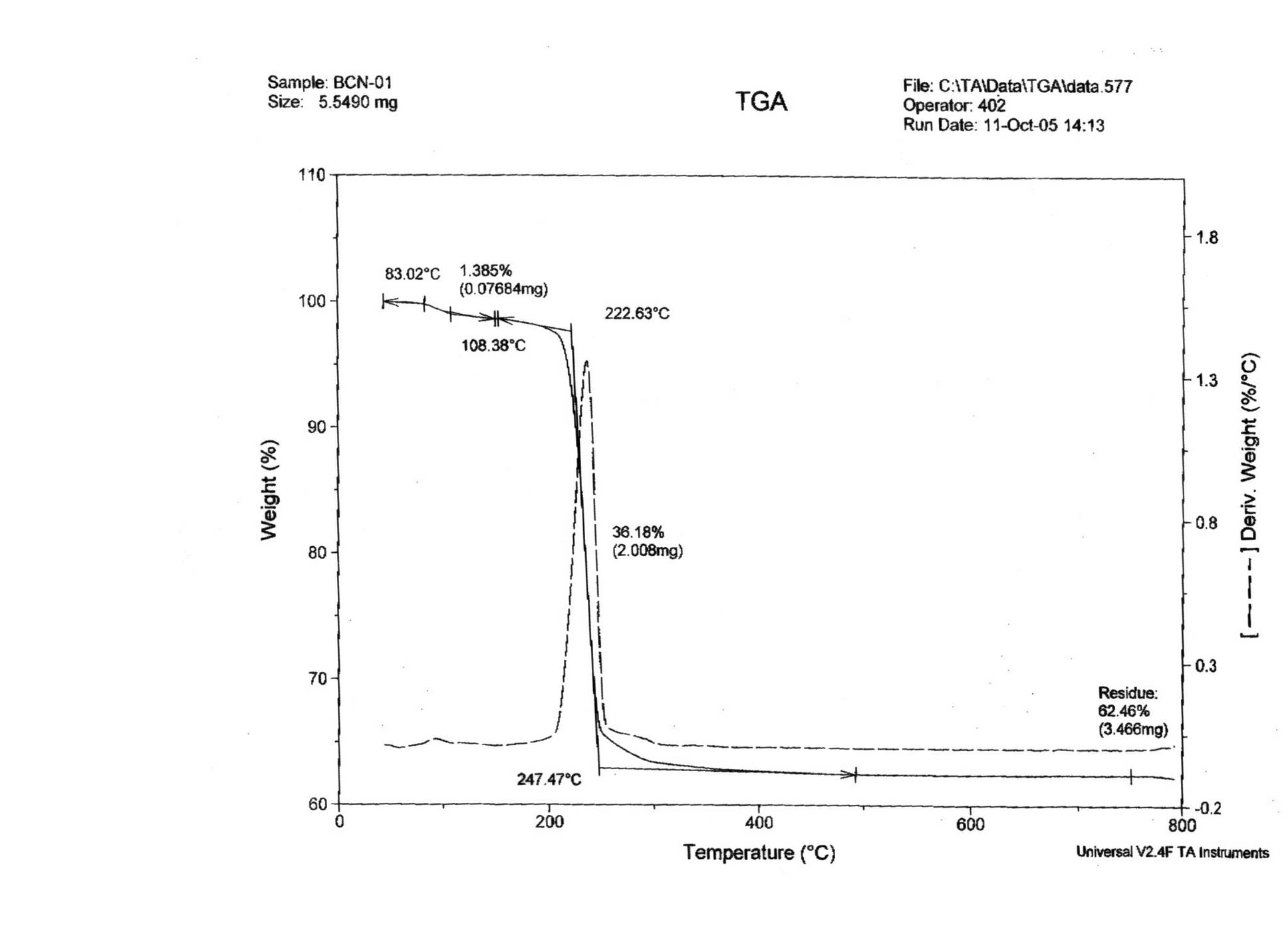

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com