Tin oxide hollow hexagon nanosheet with hierarchical structure, and preparation method thereof

A layered structure and nanosheet technology, applied in tin oxide, nanotechnology, etc., can solve the problem of difficult control of template removal, and achieve good application prospects, easy control, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

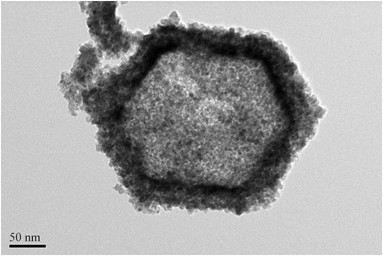

[0020] Example 1 Preparation of hollow hexagonal tin oxide nanosheets with single-layer structure

[0021] Disperse 1.38 grams of cadmium hydroxide in a mixed solution with a volume ratio of ethanol and water of 0.37:1, ultrasonically disperse for 30 minutes, add 0.9 grams of urea and 0.1 grams of potassium stannate to the above solution, and stir magnetically for 20 minutes. Transfer to a 50ml reactor and react at 170°C for 36 hours. The white precipitate was washed with deionized water, dried at 80°C, and sintered at 600°C for 1 hour to obtain hollow hexagonal tin oxide nanosheets with a single-layer structure. The transmission electron microscope photos are as follows: figure 1 shown.

Embodiment 2

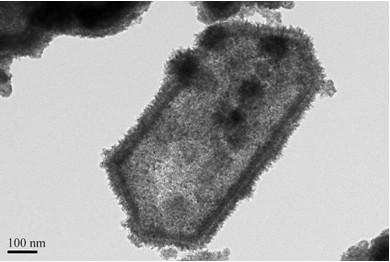

[0022] Example 2 Preparation of double-layer hollow hexagonal tin oxide nanosheets

[0023] Disperse 1.4 grams of hollow hexagonal tin oxide nanosheets obtained in Example 1 in a mixed solution with a volume ratio of ethanol and water of 0.37:1, ultrasonically disperse for 30 minutes, add 0.9 grams of urea and 0.1 grams of potassium stannate to the above solution , magnetically stirred for 20 min, and the uniformly stirred solution was transferred to a 50 ml reaction kettle, and reacted at 170° C. for 36 hours. The white precipitate was washed with deionized water, dried at 80°C, and sintered at 600°C for 1 hour to obtain hollow hexagonal tin oxide nanosheets with a double-layer structure. The transmission electron microscope photos are as follows: figure 2 shown.

Embodiment 3

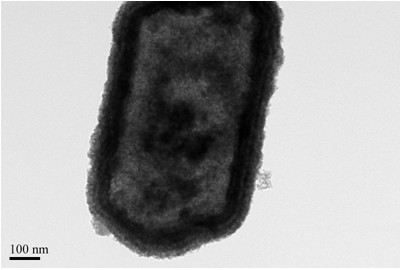

[0024] Example 3 Preparation of double-layer hollow hexagonal tin oxide nanosheets

[0025] Disperse 1.0 g of the hollow tin oxide nanosheets obtained in Example 1 in a mixed solution with a volume ratio of ethanol and water of 0.37:1, ultrasonically disperse for 30 min, add 0.9 g of urea and 0.1 g of potassium stannate to the above solution, and stir magnetically After 20 minutes, the uniformly stirred solution was transferred to a 50ml reaction kettle, and reacted at 170°C for 36 hours. The white precipitate was washed with deionized water, dried at 80°C, and sintered at 600°C for 1 hour to obtain hollow hexagonal tin oxide nanosheets with a three-layer structure. The transmission electron microscope photos are as follows: image 3 shown. Figure 4 It is the I-V curve of the battery corresponding to the hollow hexagonal tin oxide nanosheet / P25 composite film electrode with layered structure of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com