Preparation method of hydroxyalkyl amide type hard water softening agent

A hydroxyalkyl amide type, hard water softener technology, applied in the field of organic chemical synthesis, can solve the problems of limited addition of metalworking fluids, insufficient solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

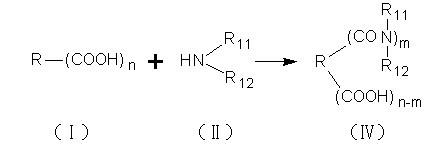

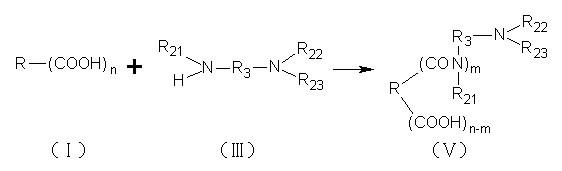

Image

Examples

Embodiment 1

[0015] In a three-necked flask equipped with a stirring device, a reflux condenser and a thermometer, add 192 grams of citric acid and 105 grams of dihydroxyethylamine, add 1.5 grams of sodium hydroxide, heat to 120 ° C for 5 hours under reduced pressure, and then further distill out the reaction Generated water, cooling the product in the there-necked bottle to prepare hydroxyalkylamide hard water softener of citric acid.

Embodiment 2

[0017] In a three-neck flask equipped with a stirring device, a reflux condenser and a thermometer, add 225 grams of ethylenediaminetetraacetic acid and 170 grams of trihydroxyethylethylenediamine, add 2.5 grams of sodium hydroxide, heat to 130 ° C and react under reduced pressure for 6 hours , further distill off the water generated by the reaction, and cool the product in the there-necked flask to obtain the ethylenediaminetetraacetic acid hydroxyalkylamide hard water softener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com