Method for preparing amino siloxane

An aminosiloxane and siloxane technology, applied in the field of preparing aminosiloxane, can solve problems such as unsatisfactory catalytic effect, and achieve the effects of good catalytic effect, high reaction selectivity and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

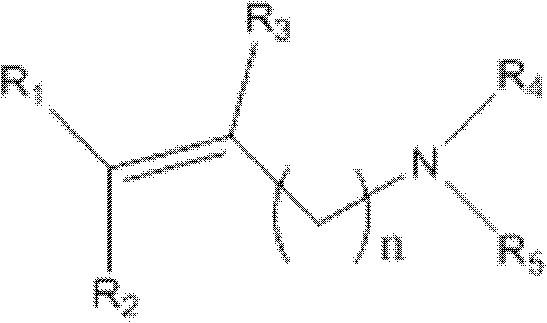

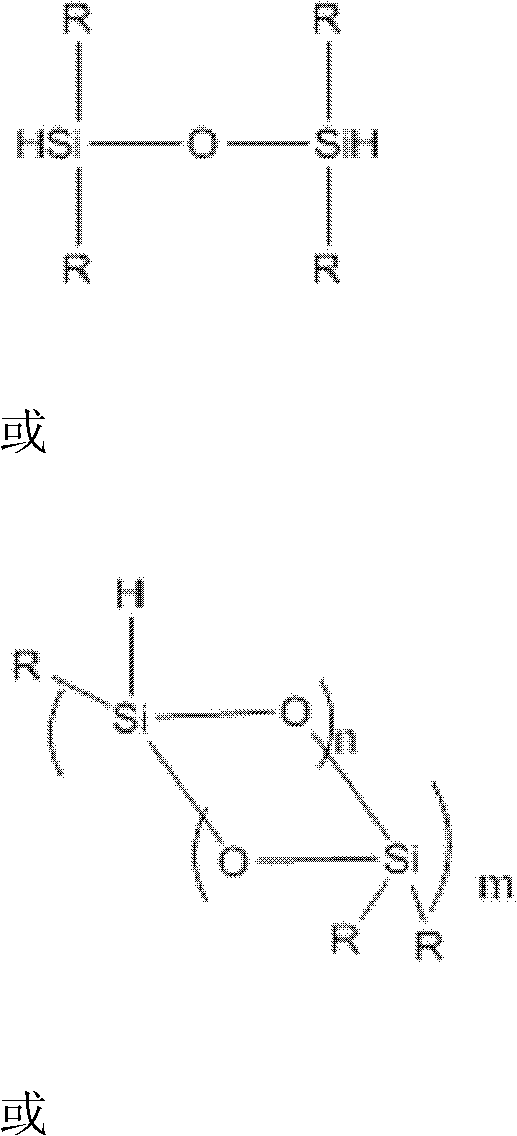

Method used

Image

Examples

Embodiment 1

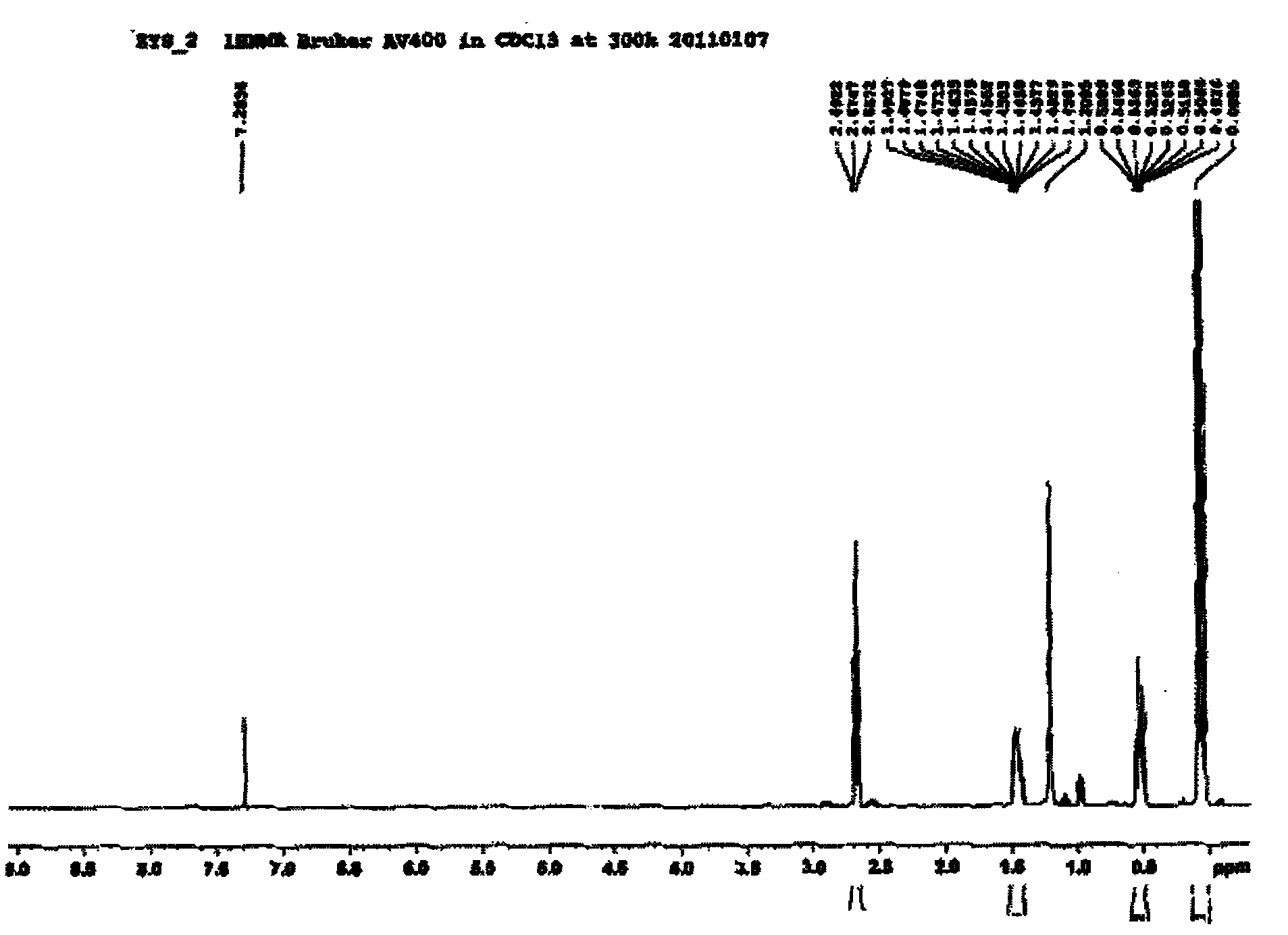

[0028] in N 2 In the replaced kontes' tube, add allylamine (150mmol) and tetramethyldihydrodisiloxane (50mmol), simethicone 0.1g, PtO 2 0.0028g, seal the reaction vessel, stir and heat at 85°C, keep the temperature for 24 hours, the infrared test shows that the silicon-hydrogen bond disappears, let it stand and cool at room temperature, filter to remove PtO 2 , remove unreacted allylamine under reduced pressure, and distill under reduced pressure to obtain product 11g, 1 H-NMR shows that the content of γ-addition products is about 95%, and the product spectrum is shown in figure 1 .

Embodiment 2

[0030] in N 2 In the replaced kontes' tube, add allylamine (150mmol) and heptamethylcyclotetrasiloxane (50mmol), simethicone 0.15g, PtO 2 0.0028g, seal the reaction vessel, stir and heat at 85°C, keep the temperature for 24 hours, the infrared test shows that the silicon-hydrogen bond disappears, let it stand and cool at room temperature, filter to remove PtO 2 , remove unreacted allylamine under reduced pressure, distill under reduced pressure, obtain product 15.8g, 1 H-NMR showed that the content of γ-addition product was about 95%.

Embodiment 3

[0032] in N 2 Replaced in the kontes' tube, adding allylamine (150mmol) and a viscosity of 50,000 centipoise, 14.75g of methyl hydrogen silicone oil with a hydrogen content of 25%, PtO 2 0.0028g, airtight reaction vessel, stir and heat at 85°C, keep the temperature for 30 hours, the silicon-hydrogen bond disappears according to the infrared test, let it cool down at room temperature, filter to remove PtO 2 , remove unreacted allylamine under reduced pressure to obtain 17.6 g of product, 1 H-NMR showed that the content of γ-addition product was about 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com