Pneumatic cooling and air purifying system

An air purification system and air purification device technology, applied in the direction of machine/engine, safety device, non-variable-capacity pump, etc., can solve the problems of not being able to store for a long time, large-capacity batteries increase risk factors, etc., to achieve strong adaptability and operation. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

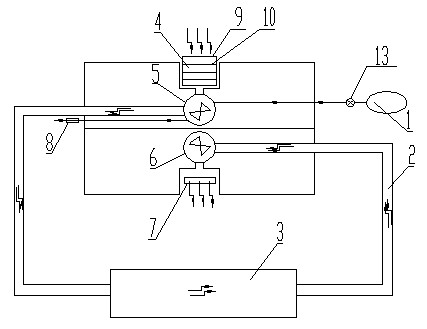

[0025] Depend on figure 1 and figure 2 A pneumatic cooling and air purification system shown includes an air purification device 4 arranged at the air suction port, and a first pneumatic fan 5 connected to the air duct 2 at the air outlet, that is, the inlet of the air duct 2 and the first pneumatic fan 5 The air outlet of the air flow channel 2 is provided with a cooling device, the end of the air flow channel 2 is provided with an outlet, and the outlet of the air flow channel 2 is provided with a second fan 6 for pressurization. Move the freely rotating impeller or be a hand fan with a handle, and the second fan 6 is convenient for sucking cold air from the air flow duct 2 into a safe place to avoid danger. The air outlet of the second fan 6 is provided with shutters 7, and the shutters 7 are used to release cold wind and adjust the angle of cold wind.

[0026] Air cleaning device 4 comprises the cabinet body 9 that the top is provided with gas inlet, and the bottom is ...

Embodiment 2

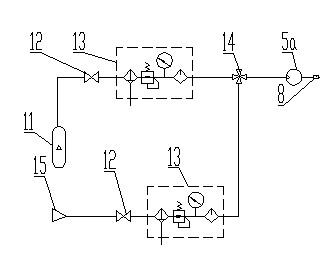

[0031] Depend on image 3 and Figure 4 A kind of pneumatic cooling and air purification system shown is different from Embodiment 1 in that: under the condition that the aforementioned air source is sufficient, the second blower is the second pneumatic blower 6 ′, and the first pneumatic blower 5 The air path of the air motor 5 a and the air motor 6 a of the second air blower 6 ′ is connected in series, and the exhaust port of the air motor 6 a of the second air blower 6 ′ is exhausted through the muffler 8 .

[0032] After replacing the second fan 6 with the second pneumatic fan 6', the compressed gas in the air source or the gas in the mine pressure air pipeline 15 enters the air motor 5a of the first pneumatic fan 5 and drives it to rotate, and the discharged gas enters The air motor 6a of the second air blower 6' drives the second air blower 6' for pressurization. This method can obtain a higher fan speed and is suitable for high-speed and low-torque fans.

Embodiment 3

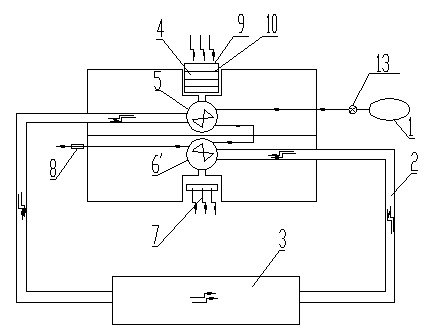

[0034] Depend on Figure 5 and Figure 6 A kind of pneumatic cooling and air purification system shown is different from Embodiment 1 in that: under the condition that the aforementioned air source is sufficient, the second fan is the second pneumatic fan 6', the storage tank 11 and the mine pressure After the air pipeline 15 is respectively connected to a switching valve 14 through an air source processing device 13, the switching valve 14 is connected to a three-way valve 18 through the pipeline, and the three-way valve 18 is connected to the first and second pneumatic valves respectively through the pipeline. The two air motors of blower fan, i.e. the air motor 5a of the first air blower 5 and the air motor 6a of the second air blower 6' are connected with the air source respectively, so that the air motor 5a of the first air blower 5 and the second air blower 6' The air path of the air motor 6a is connected in parallel, and the air motor 5a of the first air blower 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com