Core-sheath composite filament for toothbrush and toothbrush obtained using the core-sheath composite filament

A toothbrush and filament technology, applied in the field of toothbrushes, can solve the problems of the toothbrush's bristle tip is easy to expand, cannot get a toothbrush, and durability declines, so as to achieve efficient removal of tartar and stains, ensure stain removal performance, and improve bristle tip expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

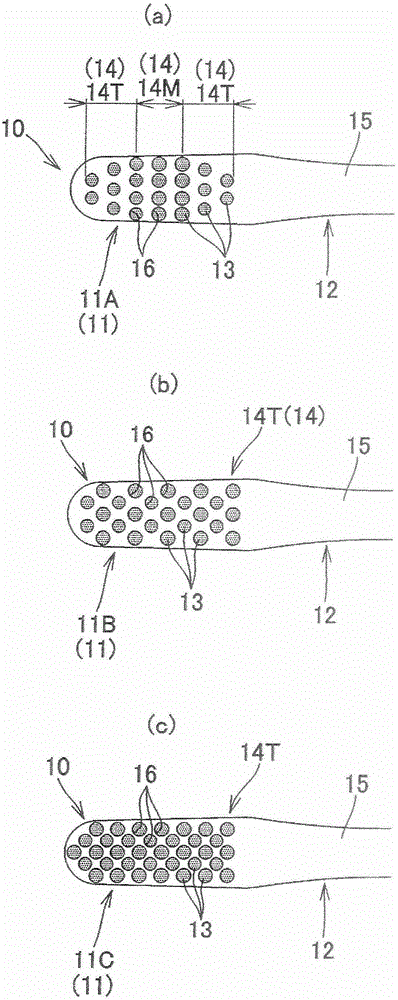

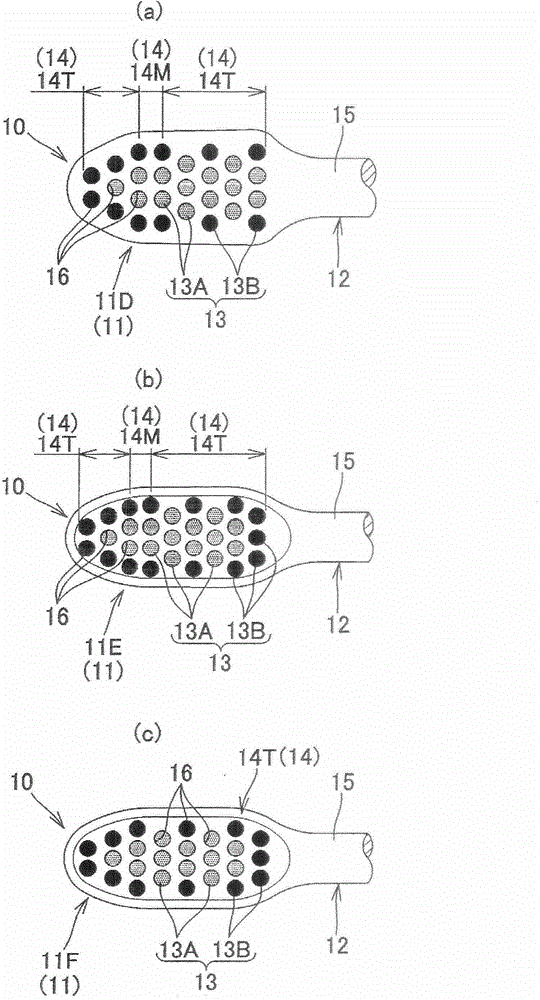

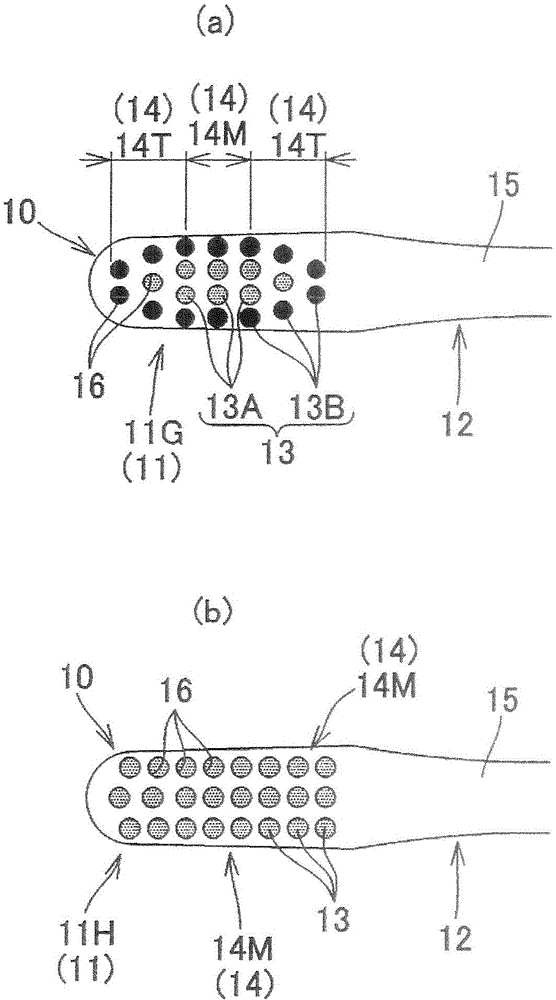

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0042] like Figure 1 ~ Figure 4 As shown, the toothbrush 10 has the handle 12 provided with the hair-planting stand 11 at the front end, and the brush part 14 which consists of a plurality of hair bundles 13 planted on the hair-planting stand 11 . The filaments constituting the bristle bundle 13 have a core 2 made of synthetic resin fibers and a sheath 3 integrally covering the core 2, wherein the sheath 3 is made of synthetic resin that is compatible with the core 2. It is composed of an elastic body, and the bundle 13 including the core-sheath composite filament 1 having a quadrangular cross section perpendicular to the longitudinal direction can be used. In addition, in this embodiment, although the case where this invention was applied to the manual toothbrush 10 was demonstrated, this invention is applicable also to the brush part of an electric toothbrush.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com