Production method of deodorized polyoxyalkylene-modified polysiloxane composition

一种聚氧化烯、聚硅氧烷的技术

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

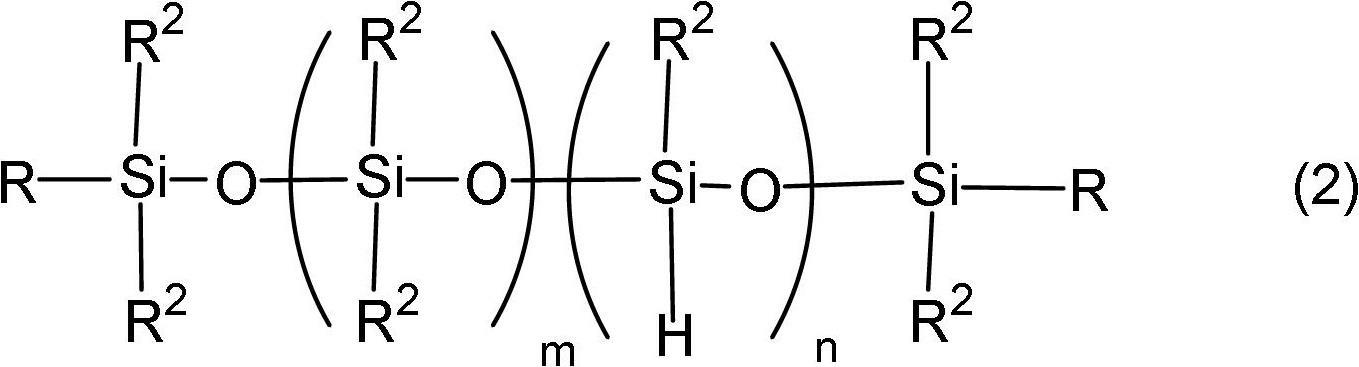

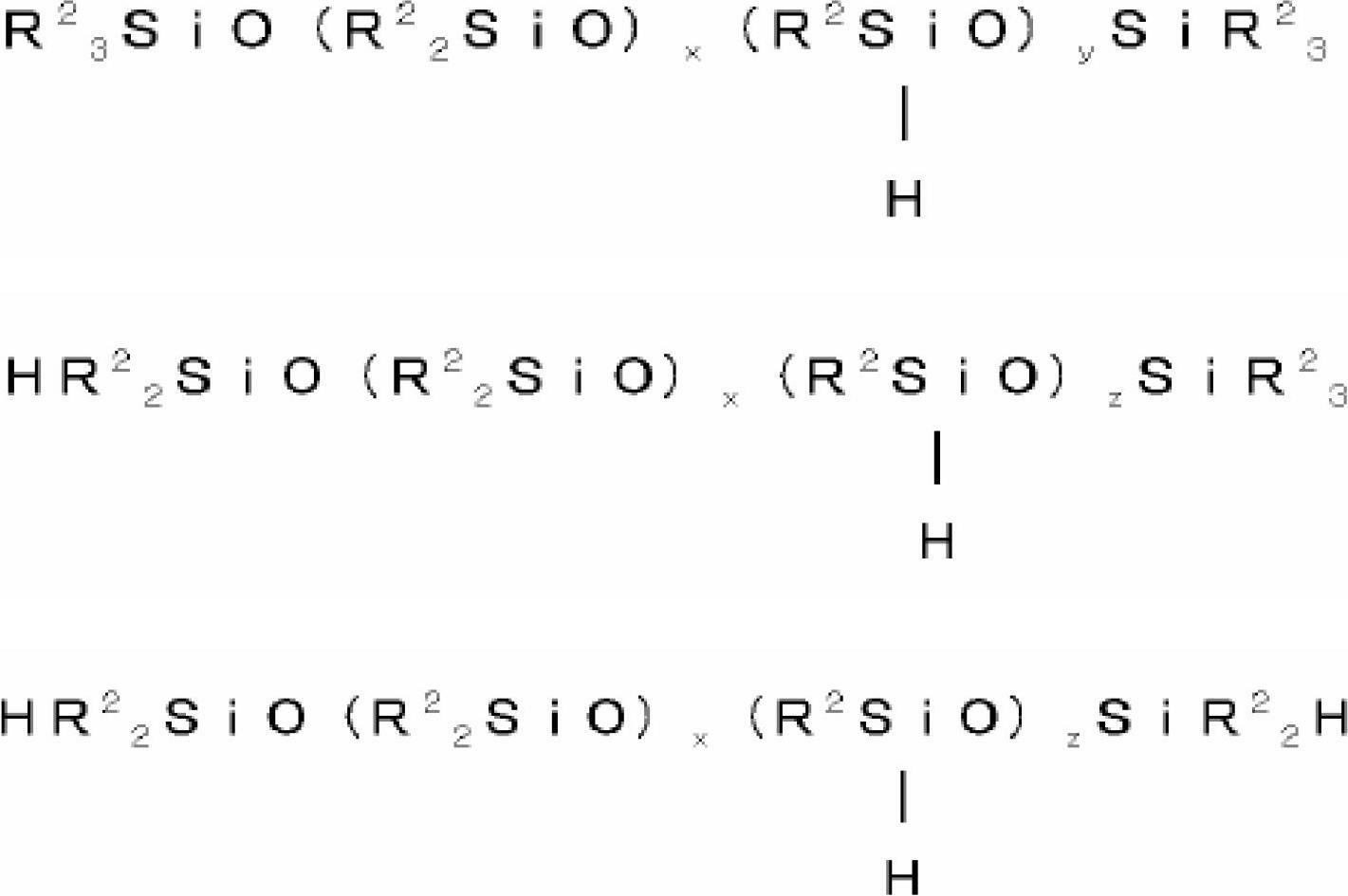

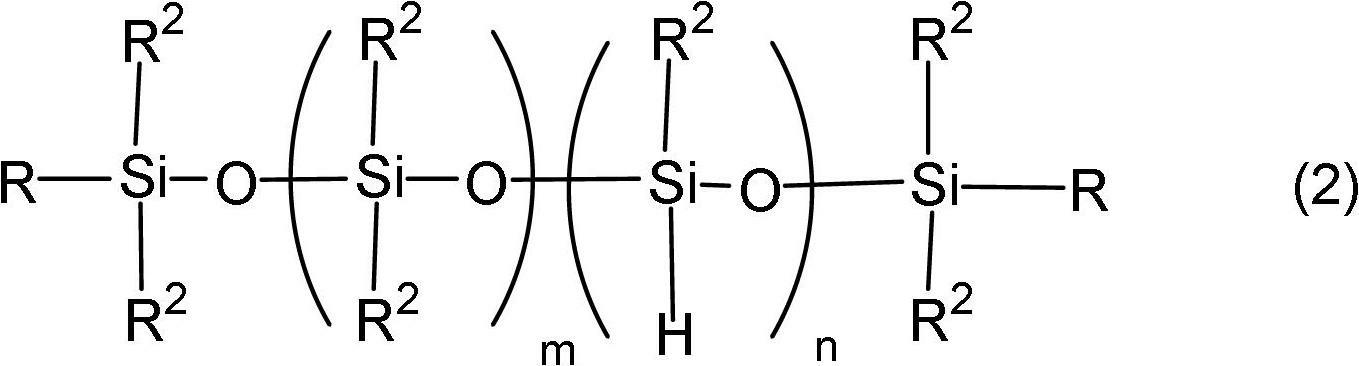

Image

Examples

Embodiment 1A

[0177] The bottle containing 100 mL of ultra-high purity alcohol (A) was opened and 4.30 g of special reagent grade trichloroacetic acid was immediately added to the bottle. The bottle was then recapped and thereafter mixed by shaking to achieve homogeneity and produce an alcoholic solution of trichloroacetic acid with an acid concentration of 4.3% (wt / vol). This solution was designated as "trichloroacetic acid solution (1A)". The production process was carried out within 1 hour before the absorbance measurement.

Embodiment 2A

[0179] Open the bottle containing 100 mL of ultra-high-purity alcohol (A) and immediately add 50 mg of 2,4-dinitrophenylhydrazine (a special reagent grade product containing an equivalent amount of water, hereinafter referred to as "2,4- DNPH"). The bottle was then recapped and 2,4-DNPH was completely dissolved in ultra-high purity alcohol (A) by holding in an ultrasonic cleaner for 5 minutes to produce a 0.025% (wt / vol) 2,4-DNPH alcoholic solution. This solution was designated as "2,4-DNPH solution (2A)". The production process was carried out within 1 hour before the absorbance measurement.

Embodiment 3A

[0181] The bottle containing 100 mL of ultra-high purity alcohol (A) was opened and 4.0 g of potassium hydroxide (pellet, special reagent grade) was immediately added to the bottle. The bottle was then recapped; mixed by shaking until the globules had disappeared; and potassium hydroxide was then completely dissolved in the ultra-high purity alcohol (A) by holding in an ultrasonic cleaner for 10 minutes to yield 4.0% (wt / vol ) Alcoholic solution of potassium hydroxide. This solution was designated as "Potassium Hydroxide Solution (3A)". The production process was carried out within 1 hour before the absorbance measurement.

[0182] [ Measurement of carbonyl value ]

[0183] 2.00 g of the sample and 23.00 g of ultra-high-purity alcohol (A) were introduced into a 50-mL screw cap bottle and mixed to prepare 25.00 g of a sample solution (Sa) having a sample concentration of 8% by mass. The compositions obtained in Comparative Examples 1, 3, 4, 5, and 6 had very high carbonyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com