Special fertilizer for Baicheng mung beans and preparation method thereof

A special fertilizer and mung bean technology, which is applied in the field of geographical indication product Baicheng mung bean special fertilizer, can solve the labor-intensive and labor-intensive problems, and achieve the effects of reducing pollution, promoting healthy growth, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

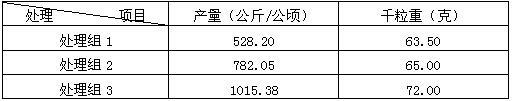

Embodiment 1

[0013] Monoammonium phosphate 250kg, ammonium sulfate 180kg, potassium sulfate 200kg, zinc sulfate 10kg, boron fertilizer 10kg, humic acid 150kg, sulfuric acid 20kg, synthetic ammonia 25kg;

[0014] The preparation method comprises the following steps: sending the following components into the drum granulator through a metering belt scale in parts by mass: 250 kg of monoammonium phosphate, 180 kg of ammonium sulfate, 200 kg of potassium sulfate, 10 kg of zinc sulfate, 10 kg of boron fertilizer, 150 kg of humic acid, Steam is introduced into the drum granulation, 20kg of sulfuric acid is sprayed synchronously through the electromagnetic flowmeter, and 25kg of synthetic ammonia is synchronously introduced through the mass flowmeter to react with ammonium sulfate and monoammonium phosphate. Granulate; the material enters the drum dryer for drying, and the exhaust gas temperature is 80°C, then enters the drum cooler to cool, and the finished particles of 2 mm are collected through ...

Embodiment 2

[0016] Monoammonium phosphate 300kg, ammonium sulfate 215kg, potassium sulfate 250kg, zinc sulfate 15kg, boron fertilizer 15kg, humic acid 250kg, sulfuric acid 25kg, synthetic ammonia 32.5kg;

[0017] The preparation method comprises the following steps: the following components are sent into the drum granulator through a metering belt scale in parts by mass: 300 kg of monoammonium phosphate, 215 kg of ammonium sulfate, 250 kg of potassium sulfate, 15 kg of zinc sulfate, 15 kg of boron fertilizer, 250 kg of humic acid, Steam is introduced into the drum granulation, 25kg of sulfuric acid is sprayed synchronously through the electromagnetic flowmeter, 32.5kg of synthetic ammonia is synchronously introduced through the mass flowmeter to react with ammonium sulfate and monoammonium phosphate, the temperature of the material is 70°C, and the pH value of the material is 6.0. Bonding and granulation; the material enters the drum dryer for drying, and the exhaust gas temperature of ...

Embodiment 3

[0019] Monoammonium phosphate 350kg, ammonium sulfate 250kg, potassium sulfate 300kg, zinc sulfate 20kg, boron fertilizer 20kg, humic acid 350kg, sulfuric acid 30kg, synthetic ammonia 40kg;

[0020] The preparation method comprises the following steps: the following components are sent into the drum granulator through a metering belt scale in parts by mass: 350 kg of monoammonium phosphate, 250 kg of ammonium sulfate, 300 kg of potassium sulfate, 20 kg of zinc sulfate, 20 kg of boron fertilizer, and granulate in the drum Steam is introduced into the medium, 30 parts of sulfuric acid are sprayed synchronously through the electromagnetic flowmeter, and 40 parts of synthetic ammonia are simultaneously introduced through the mass flowmeter to react with ammonium sulfate and monoammonium phosphate. Granules; the material enters the drum dryer for drying, and the exhaust gas temperature of the drying is 95°C, then enters the drum cooler to cool, and the finished particles of 4mm are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com