Preparation method of meta-aminophenol-formaldehyde resin spheres and preparation method of carbon spheres

A m-aminophenol and formaldehyde resin technology, applied in the field of polymers, can solve the problems of low product yield, rough surface, small adjustability, etc., and achieve the effect of high yield and high monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of m-aminophenol-formaldehyde resin ball, comprises the following steps:

[0030] Catalyst, m-aminophenol and formaldehyde are dissolved in solvent, and m-aminophenol-formaldehyde resin balls are obtained after polymerization;

[0031] The catalyst is ammonia and / or ethylenediamine;

[0032] The solvent is an aqueous solution, an alcoholic solution or a mixed solution of water and alcoholic compounds.

[0033] In the present invention, firstly, the catalyst, m-aminophenol and formaldehyde are dissolved in a solvent to obtain a mixed solution, and the catalyst is ammonia water and / or ethylenediamine, preferably ammonia water. In the present invention, there is no special limitation on the order in which the catalyst, m-aminophenol and formaldehyde are dissolved in the solvent, and the technical solution for preparing phenolic resin well known to those skilled in the art can be used. In the present invention, the m-ami...

Embodiment 1

[0053] Add 32.7 mg of m-aminophenol to a mixed solution of 12 mL of water and 4.8 mL of methanol, stir and dissolve at 30 °C for 10 minutes, then add 0.6 μL of ammonia water with a mass concentration of 28%, and then stir the resulting mixed solution for 20 Minutes later, 46 μL of formaldehyde was added thereto, and after stirring for 4 hours, the resulting mixed solution was placed in a 20 mL reaction kettle, and stirred at 100° C. for 24 hours. The obtained reaction product was centrifuged at 8000 rpm for 5 minutes, the centrifuged solid was washed twice with water, and dried at 80° C. for 12 hours to obtain m-aminophenol-formaldehyde resin balls.

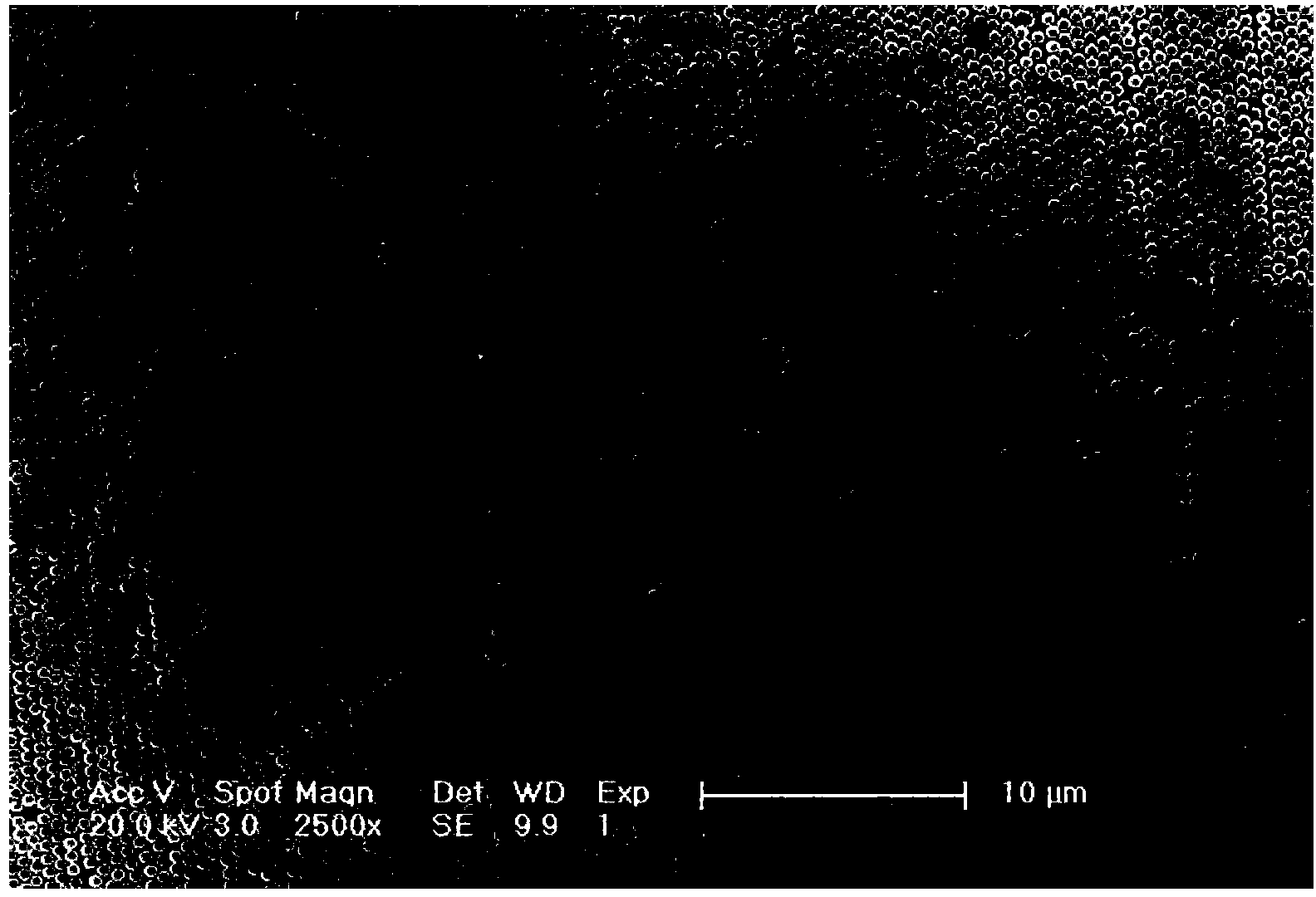

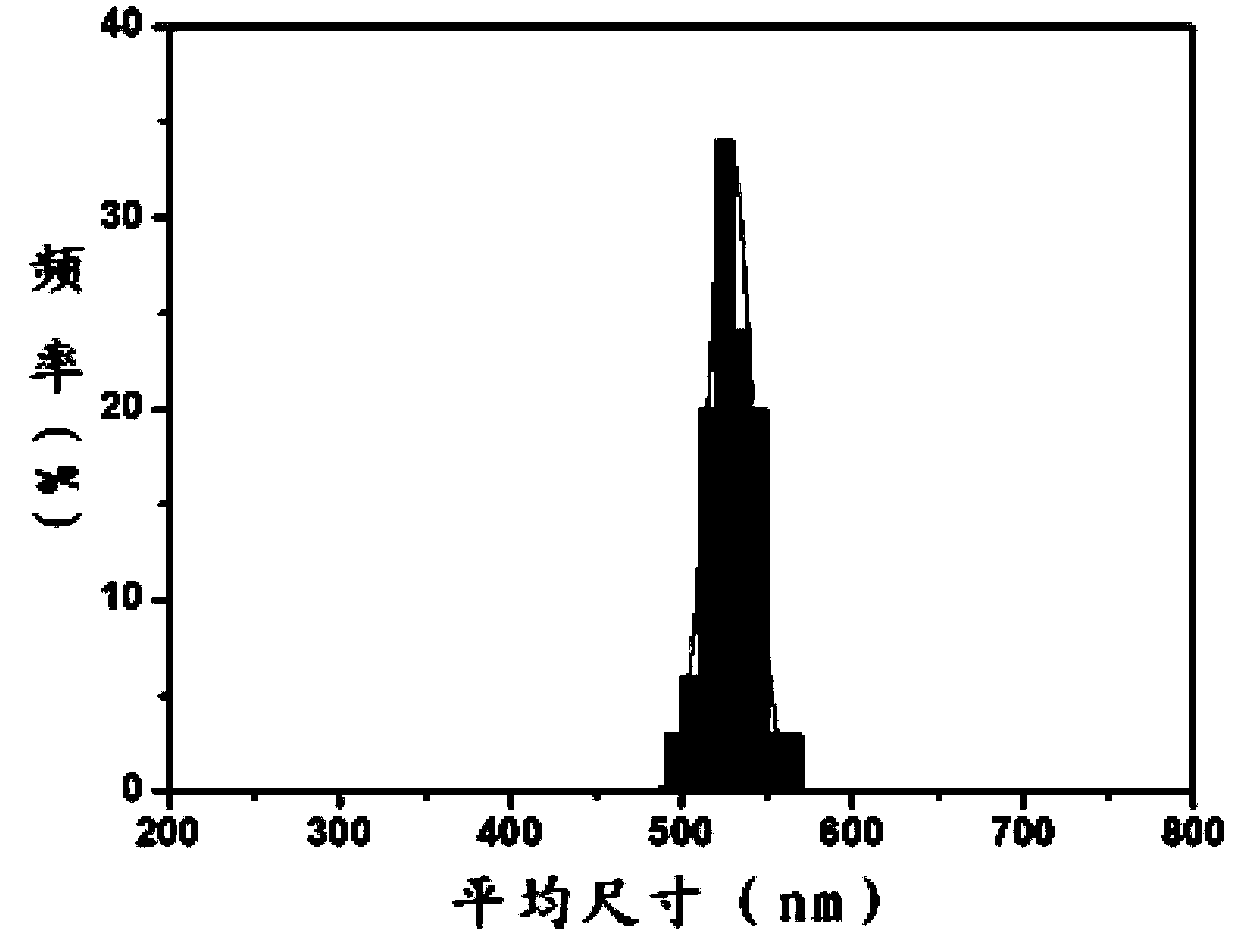

[0054] The mass of the m-aminophenol-formaldehyde resin balls weighed by the present invention is 47.7 mg, and the calculated yield is 94%. The present invention carries out scanning electron microscope scanning analysis to the m-aminophenol-formaldehyde resin ball obtained, the result is as follows figure 1 as shown, figure 1 ...

Embodiment 2

[0060] Add 32.7 mg of m-aminophenol to a mixed solution of 12 mL of water and 4.8 mL of methanol, stir and dissolve at 30°C for 10 minutes, then add 12 μL of ammonia water with a mass concentration of 28%, and then stir the resulting mixed solution for 20 minutes 46 μL of formaldehyde was added thereto, and after stirring for 4 hours, the resulting mixed solution was placed in a 20 mL reaction kettle, and stirred at 100° C. for 24 hours. The obtained reaction product was centrifuged at 8000 rpm for 5 minutes, the centrifuged solid was washed twice with water, and dried at 80° C. for 12 hours to obtain m-aminophenol-formaldehyde resin balls.

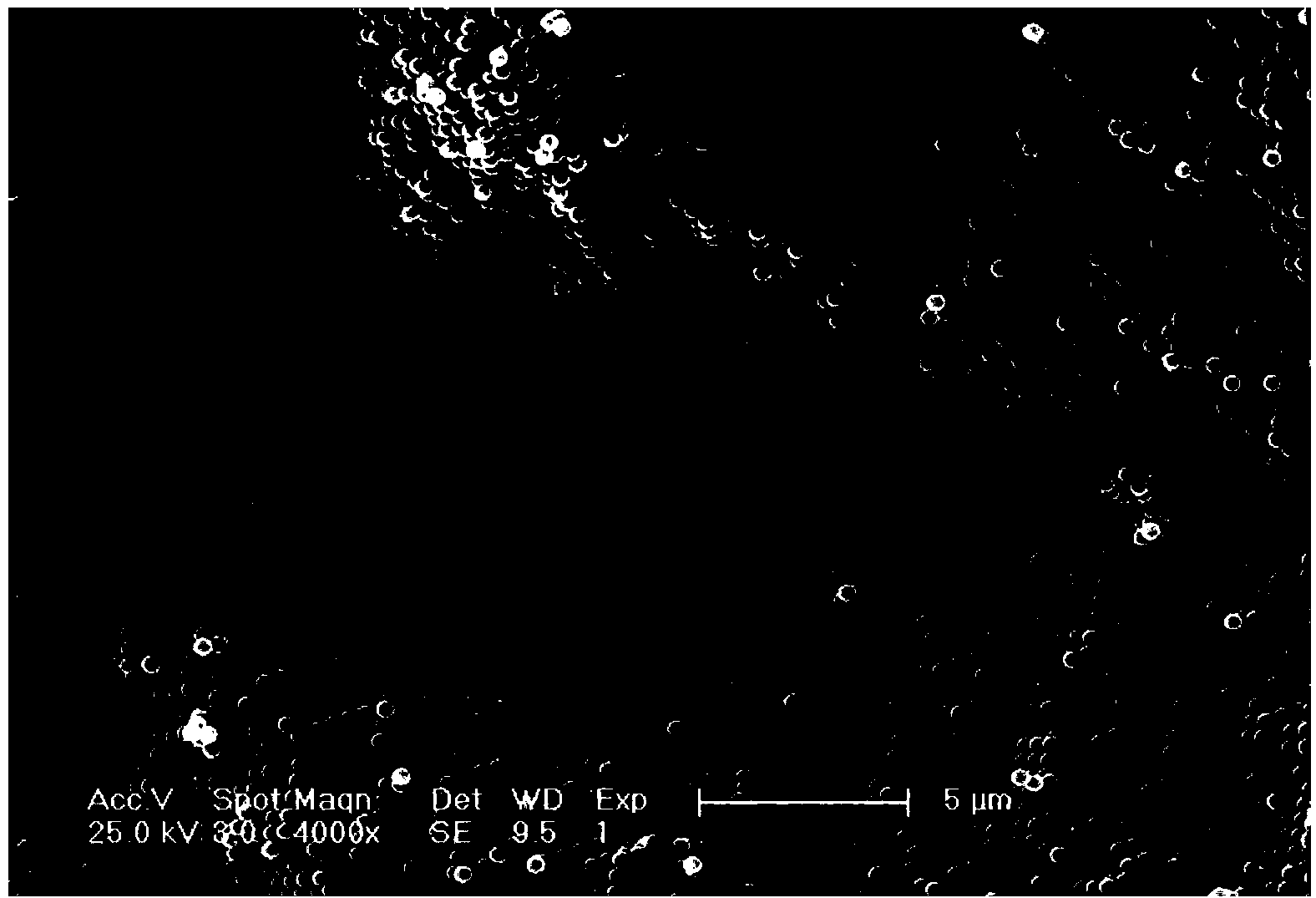

[0061] The mass of the m-aminophenol-formaldehyde resin balls weighed in the present invention is 46.6 mg, and the calculated yield is 92.0%. The present invention carries out scanning electron microscope scanning analysis to the m-aminophenol-formaldehyde resin ball obtained, the result shows that the phenolic resin ball prepared by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com