Switching method for first-stage peroxide-roasting at high temperature and second-stage underoxide-roasting at low temperature and equipment thereof

A peroxy-baking, high-temperature technology, used in lighting and heating equipment, waste heat treatment, furnace components, etc., can solve problems such as inability to achieve refractory gold mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

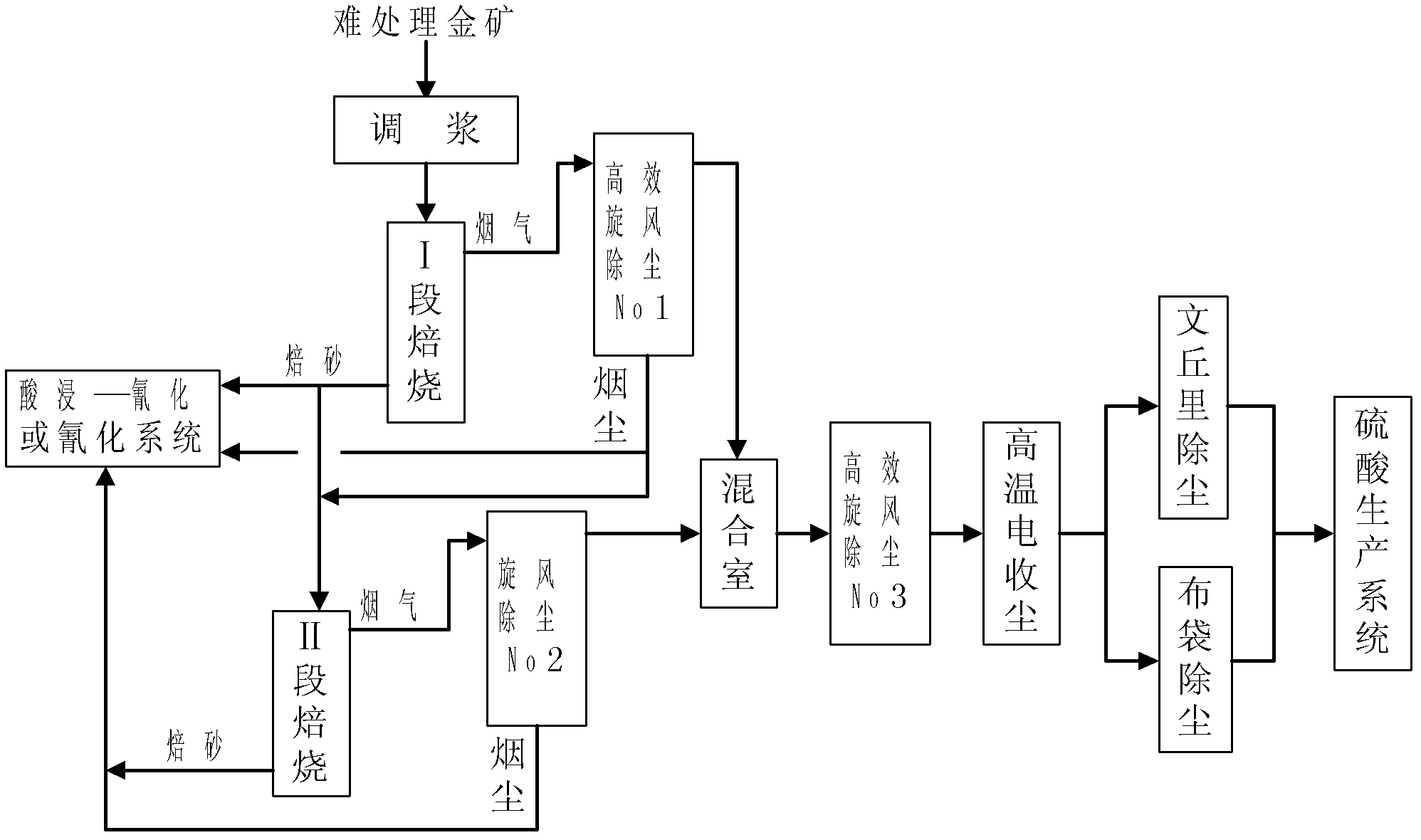

Image

Examples

Embodiment 1

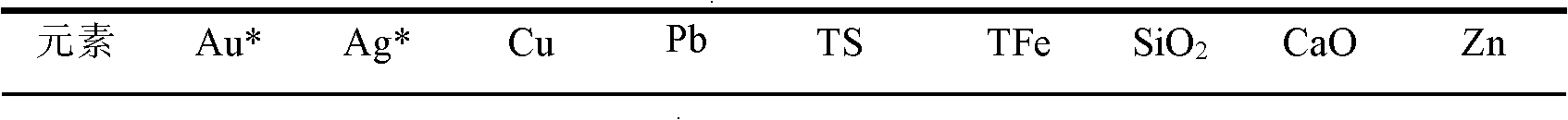

[0023] A high-copper refractory gold concentrate, the chemical analysis results of the ore sample are shown in Table 1.

[0024] Table 1 Analysis results of chemical composition of high-copper refractory gold concentrate / %

[0025]

[0026]

[0027] The method and equipment for switching between one-stage high-temperature peroxygen roasting and two-stage low-temperature hypoxic roasting, when processing high-copper gold concentrates, adopt a one-stage high-temperature peroxygen process for roasting, including the following steps in sequence.

[0028] Step 1: Put the high-copper gold concentrate with a particle size of -200 mesh and 89.5% into the mechanical agitation slurry tank to adjust to a slurry with a slurry concentration of about 70%, and then use double-ring atomization feeding technology to blow into the first section The boiling layer of the boiling roaster;

[0029] Step 2: Carry out a stage of roasting for 60 minutes at a temperature of 630°C and oxygen of 1...

Embodiment 2

[0034] A high-carbon refractory gold concentrate, the chemical analysis results of ore samples are shown in Table 3.

[0035] Table 3 Analysis results of chemical composition of high-carbon refractory gold concentrate / %

[0036]

[0037] The method and equipment for switching between one-stage high-temperature peroxygen roasting and two-stage low-temperature hypoxic roasting, when processing high-carbon gold concentrate, adopts one-stage high-temperature peroxygen process for roasting, including the following steps in sequence.

[0038] Step 1: Put the high-carbon gold concentrate with a particle size of -320 mesh and 81.46% into the mechanical agitation slurry tank to adjust to a slurry with a slurry concentration of about 70%, and then use double-ring atomization feeding technology to blow into the first section The boiling layer of the boiling roaster;

[0039] Step 2: Carry out one-stage roasting for 90 minutes at a temperature of 680°C and 130% of the theoretically requ...

Embodiment 3

[0045] Table 5 shows the chemical analysis results of a high-arsenic refractory gold concentrate.

[0046] Table 5 Analysis results of chemical composition of high-arsenic refractory gold concentrate / %

[0047]

[0048] The method and equipment for switching between one-stage high-temperature peroxygen roasting and two-stage low-temperature under-oxygen roasting, when processing high-arsenic gold concentrates, adopt the I-stage under-oxygen and II-stage peroxygen processes for roasting, including the following steps in sequence.

[0049] Step 1: Add -200 mesh high-arsenic gold concentrate with a density of 91.08% into the mechanical agitation slurry mixing tank to adjust the slurry with a slurry concentration of about 70%, and then use the double-ring atomization feeding technology with its own intellectual property rights. material;

[0050] Step 2: Carry out stage I roasting for 60 minutes at a roasting temperature of 580°C and 90% of the theoretically required amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com