Colored curable resin composition

A technology of curable resin and composition, which is applied in the direction of copying/marking methods, printing, instruments, etc., can solve the problem of lightness reduction, and achieve the effect of high lightness and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

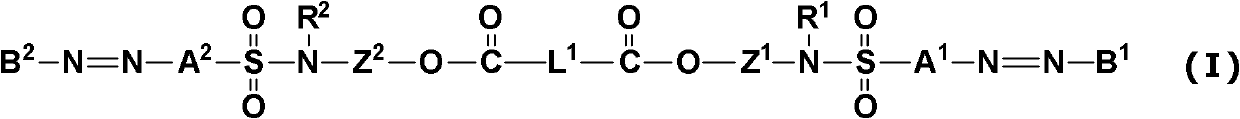

Method used

Image

Examples

Embodiment

[0308] The following examples are given to further specifically illustrate the present invention. Unless otherwise specified, "%" and "part" in an example are mass % and a mass part.

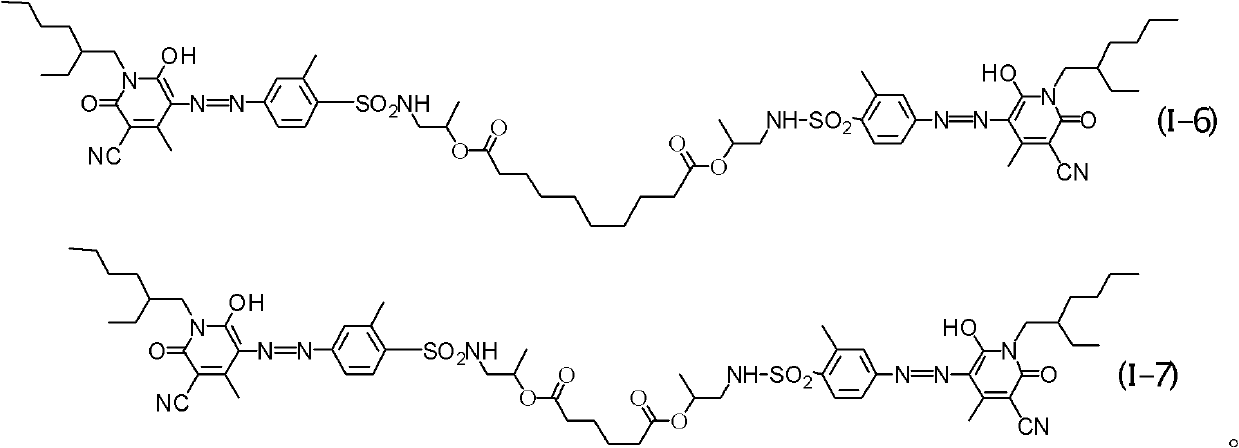

Synthetic example 1

[0310] After adding 250 parts of water and 50 parts of N-methylpyrrolidone to 25.0 parts of o-toluidine-4-sulfonic acid tetrahydrate represented by formula (a-1), adjust the pH with 30% aqueous sodium hydroxide solution under ice cooling to 7-8. The following operations were performed under ice cooling. 18.4 parts of sodium nitrite was added and stirred for 30 minutes. 64.8 parts of 35% hydrochloric acid were gradually added in small amounts to obtain a brown solution, which was then stirred for 2 hours. An aqueous solution obtained by dissolving 16.7 parts of sulfamic acid in 170 parts of water was added to the reaction solution and stirred to obtain a suspension containing a diazonium salt.

[0311]

[0312] After adding 173 parts of water and 19 parts of N-methylpyrrolidone to 19.3 parts of 1-butyl-3-cyano-4-methyl-6-hydroxypyridin-2-one represented by formula (c-1), The pH was adjusted to 8-9 with 30% aqueous sodium hydroxide solution under ice cooling.

[0313] ...

Synthetic example 2

[0326] After adding 200 parts of water and 50 parts of N-methylpyrrolidone to 25.0 parts of m-toluidine-4-sulfonic acid represented by formula (a-2), adjust the pH to 7~7 with 30% aqueous sodium hydroxide solution under ice cooling. 8. The following operations were performed under ice cooling. 27.6 parts of sodium nitrite was added and stirred for 30 minutes. 97.3 parts of 35% hydrochloric acid were gradually added in small amounts to obtain a brown solution, which was then stirred for 2 hours. An aqueous solution obtained by dissolving 25.1 parts of sulfamic acid in 250 parts of water was added to the reaction solution and stirred to obtain a suspension containing a diazonium salt.

[0327]

[0328] After adding 260 parts of water and 28.9 parts of N-methylpyrrolidone to 28.9 parts of 1-butyl-3-cyano-4-methyl-6-hydroxypyridin-2-one represented by formula (c-1), The pH was adjusted to 8-9 with 30% aqueous sodium hydroxide solution under ice cooling.

[0329]

[0330]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com