Coal pitch mixture and preparation method thereof

A technology of coal tar and mixture, which is used in building thermal insulation materials, building components, buildings, etc., can solve problems such as large energy fuels, and achieve the effects of improving high temperature performance, reducing construction temperature and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

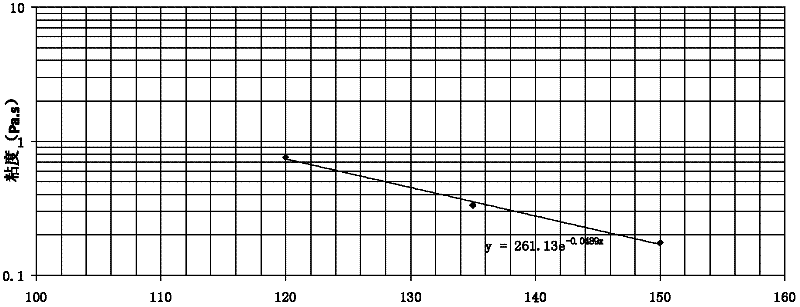

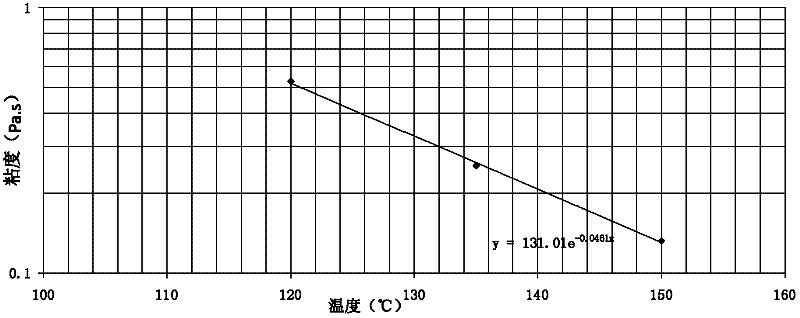

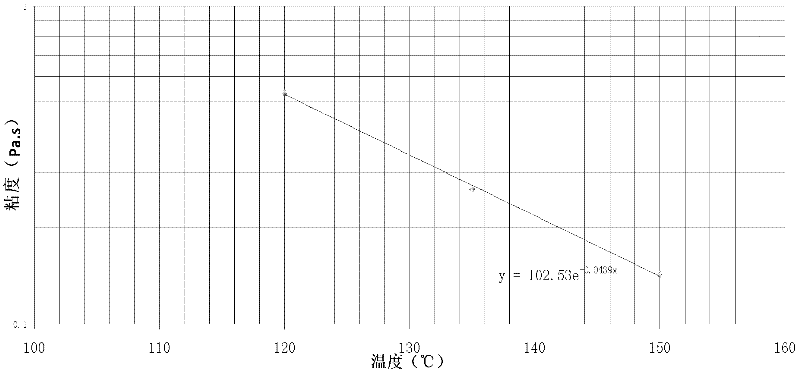

Image

Examples

Embodiment 1

[0035] Heat 70# base petroleum asphalt with a mass ratio of 77% to 150°C, add crushed and sieved coal tar pitch powder with a mass ratio of 15%, stir until the coal tar pitch is dissolved in petroleum pitch, add 3% magnesium alkylate, 5% Low-molecular-weight polyethylene is sheared at a speed of 4000r / min for 20 minutes, and the road coal tar pitch product is obtained by dissolving evenly.

Embodiment 2

[0037] Heat the 70# base petroleum asphalt with a mass ratio of 82% to 130°C, add crushed and sieved coal tar pitch powder with a mass ratio of 10%, stir until the coal tar pitch is dissolved in the petroleum pitch, add 4% zinc alkylate, 4% Low-molecular-weight polyethylene is sheared at a speed of 4000r / min for 30 minutes, and the road coal tar pitch product is obtained by dissolving evenly.

Embodiment 3

[0039] Heat 70# base petroleum asphalt with a mass ratio of 75% to 130°C, add crushed and sieved coal tar pitch powder with a mass ratio of 15%, stir until the coal tar pitch is dissolved in petroleum pitch, add 6% sodium alkylate, 4% Low-molecular-weight polyethylene is sheared at a speed of 4000r / min for 25 minutes, and the road coal tar pitch product is obtained by dissolving evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com