Three-knot cascading solar battery and preparation method thereof

A solar cell, triple-junction technology, applied in the field of solar cells, can solve the problems of increasing the cost and difficulty of cell manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

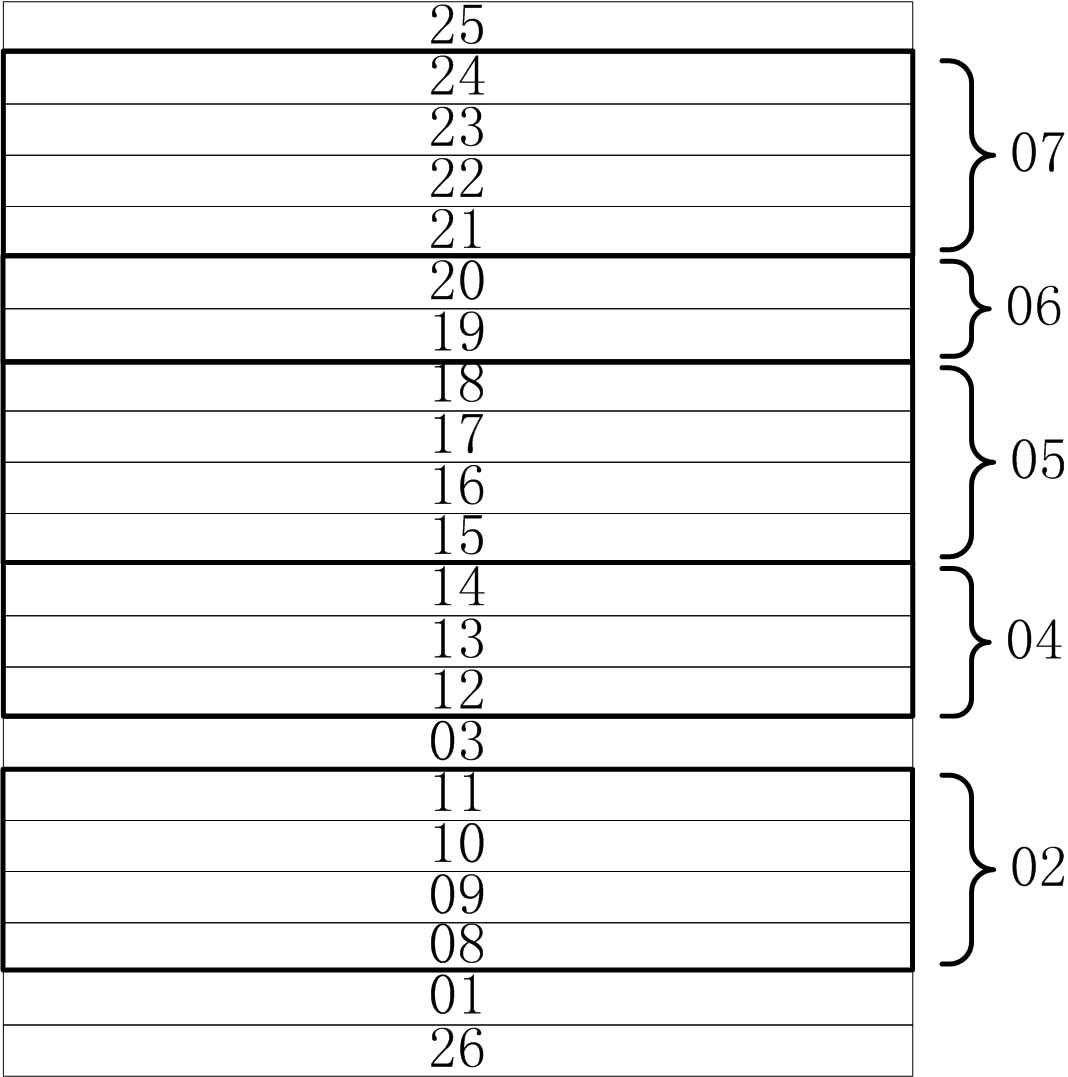

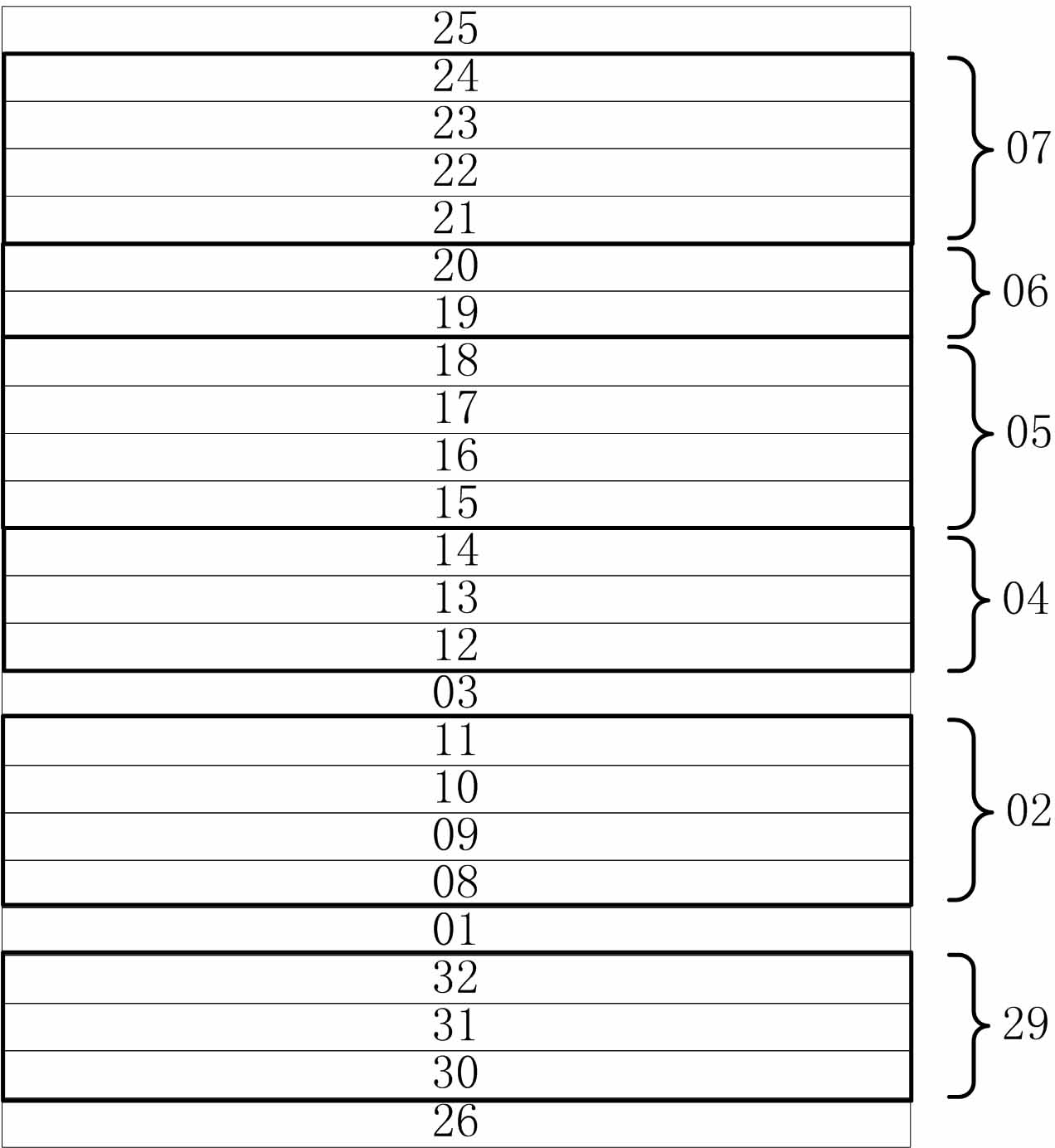

[0027] figure 1 Shown is a schematic structural view of the first embodiment of the triple-junction cascaded solar cell of the present invention.

[0028] This embodiment provides a GaInP / GaAs / InGaAs triple-junction cascaded solar cell grown based on the lattice transformation method, including a substrate 26, and a first graded transition layer 01, an InGaAs Cell 02 , second graded transition layer 03 , first tunnel junction 04 , GaAs sub-cell 05 , second tunnel junction 06 , GaInP sub-cell 07 and GaAs contact layer 25 . The three sub-cells are connected in series through a tunnel junction.

[0029] The triple-junction cascaded solar cell uses GaAs or Ge as the substrate 26 and is grown in a frontal growth manner. The bottom InGaAs sub-cell 02 is an InGaAs single-junction cell, which is lattice-mismatched with GaAs; the GaInP / GaAs double-junction cell composed of the top-layer GaInP sub-cell 07 and GaAs sub-cell 05 is lattice-matched with GaAs. The above-mentioned single-j...

no. 2 Embodiment approach

[0044] This embodiment provides a figure 1 The method for growing and preparing the GaInP / GaAs / InGaAs triple-junction cascaded solar cell includes growing the first graded transition layer 01, the InGaAs sub-cell 02, and the second graded transition layer 03 sequentially on the substrate 26 by using a front-mount growth method. , a first tunnel junction 04 , a GaAs subcell 05 , a second tunnel junction 06 , a GaInP subcell 07 and a GaAs contact layer 25 . The three sub-cells are connected in series through a tunnel junction.

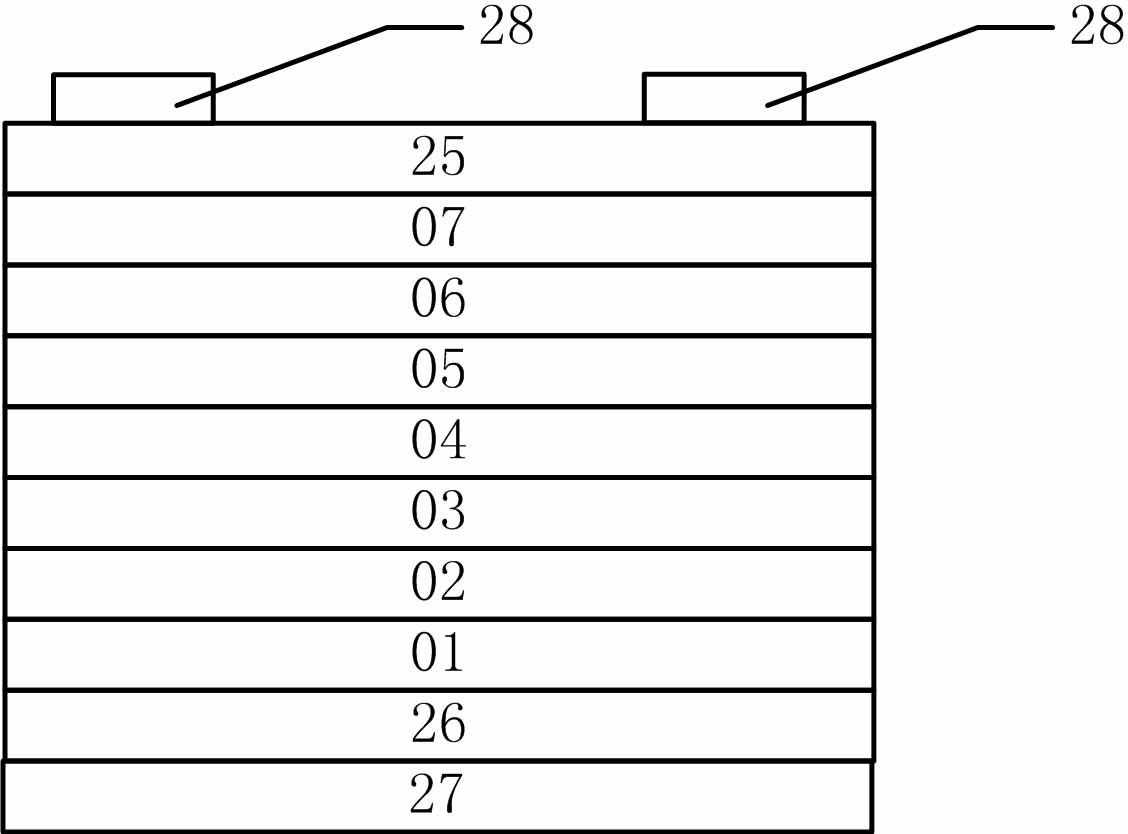

[0045] The method for preparing the above-mentioned triple-junction cascaded solar cell further includes the preparation steps of preparing the upper electrode 28 and the lower electrode 27, and the preparation step of the upper electrode 28 is to prepare the upper electrode 28 directly on the exposed surface of the GaAs contact layer 25 The step of preparing the lower electrode 27 is to prepare the lower electrode 27 on the exposed surface of the subst...

Embodiment 1

[0058] In this embodiment, a method for preparing a GaInP / GaAs / InGaAs triple-junction cascaded solar cell grown by a lattice anomaly growth method is provided, comprising the following steps:

[0059] (1) GaInP / GaAs / InGaAs triple-junction cascaded solar cells are grown by MOCVD (Metal Organic Chemical Vapor Deposition, metal organic compound chemical vapor deposition) method, and its structure is as follows figure 1 Shown:

[0060] (1) Grow P-type doped 4×10 on the substrate 26 of P-type GaAs or Ge 17 cm -3 2.6 µm Al y Ga 1-x-y In x The first graded transition layer 01 of As, to realize the transition from GaAs lattice constant to InGaAs lattice constant;

[0061] (2) in Al y Ga 1-x-y In x On the first graded transition layer 01 of As, the P-type doping concentration is about 1×10 18 cm -3 The 0.1 micron AlGaInAs 08 is used as the first back field layer 08 of the InGaAs subcell 02, and then the P-type doping concentration is grown on the first back field laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com