Ultrasound-assisted method for extracting betacyanin from suaeda salsa

A Suaeda salsa, ultrasonic-assisted technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of low yield, limited raw materials and technological level of betalain production, and high cost, and achieves extraction. Simple method, guaranteed natural and nutritious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

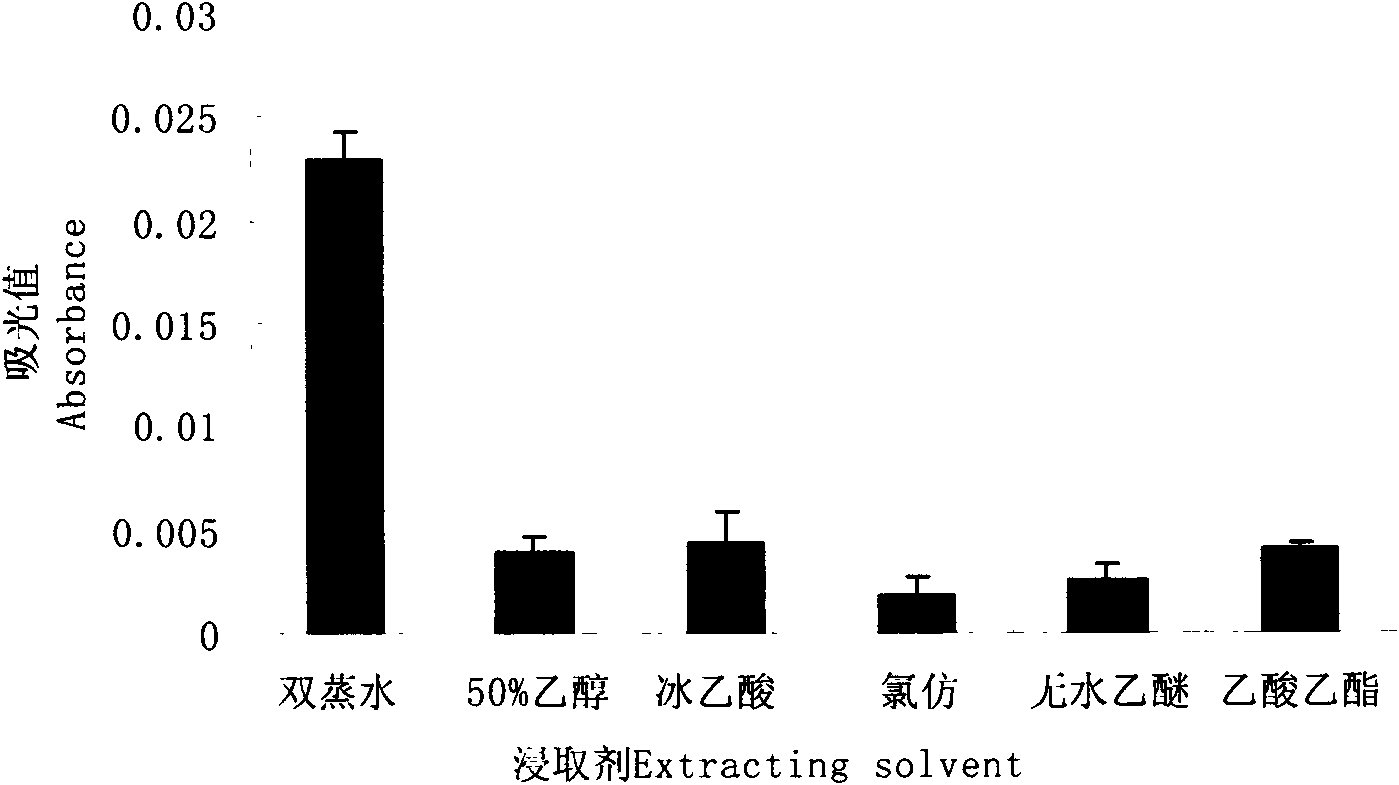

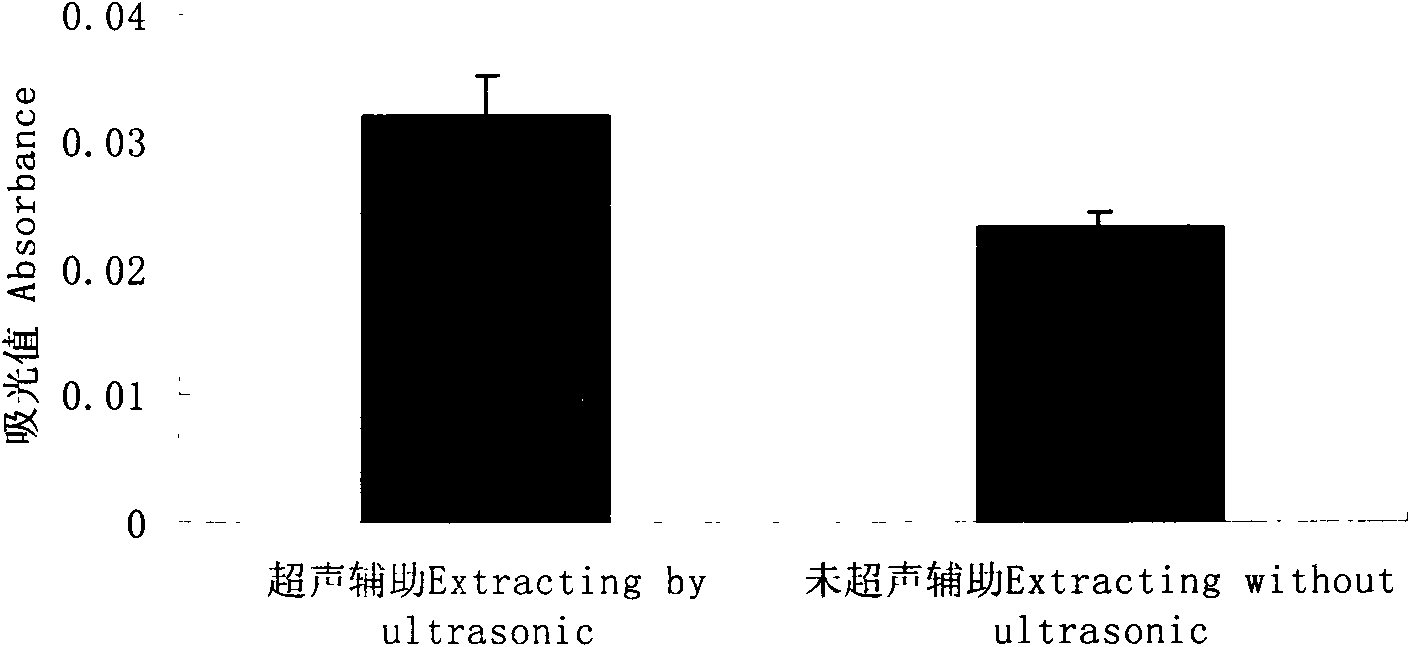

Method used

Image

Examples

example 1

[0020] Example 1: Collect fresh stems and leaves of Suaeda salsa, dry them in an oven at 60°C, crush them with a small grinder, and pass through a 40-mesh sieve. Weigh 10g of dry powder, add 100ml of double-distilled water, stir, under 600W ultrasonic power, the temperature is controlled at 40℃, for 20min, then add 400ml of double-distilled water to the mixed solution, and let it stand for 30min after stirring. Filter with qualitative filter paper, centrifuge the filtrate at 5000g for 10min, take the supernatant, concentrate it with a vacuum rotary evaporator, dry and pulverize to obtain betaine powder.

example 2

[0021] Example 2: The fresh stems and leaves of Suaeda salsa were collected, dried in an oven at 80°C, crushed with a small grinder, and passed through a 60-mesh sieve. Weigh 10g of dry powder, add 200ml of double distilled water, stir, under 600W ultrasonic power, the temperature is controlled at 40 ℃, lasted 15min, then add 400ml of double distilled water to the mixed solution, after stirring, let stand for 20 minutes, the extract Filter with qualitative filter paper, centrifuge the filtrate at 5000g for 10min, take the supernatant, concentrate and dry it with a vacuum rotary evaporator to obtain betaine lumps.

example 3

[0022] Example 3: The fresh stems and leaves of Suaeda salsa were collected, dried in an oven at 80°C, crushed with a small grinder, and passed through a 60-mesh sieve. Weigh 10g of dry powder, add 200ml ethanol (50%), stir, under 600W ultrasonic power, the temperature is controlled at 40°C for 15min, then add 300ml ethanol (50%) to the mixed solution, and let stand for 20min after stirring. The extract was filtered with qualitative filter paper, the filtrate was centrifuged at 5000 g for 10 min, the supernatant was taken, and the supernatant was concentrated, dried, and crushed with a vacuum rotary evaporator to obtain beetatin powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com