Thifluzamide-containing ultra low volume liquid formulation

An ultra-low volume liquid preparation, thifuramide technology, applied in the field of pesticides, can solve the problems of increasing the dosage and spraying times, increasing the labor intensity, increasing the cost of prevention and control, and increasing the difficulty of preventing and controlling germs, so as to save pesticides and prevent and control bacteria. Timely and insecticidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

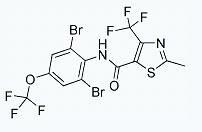

Image

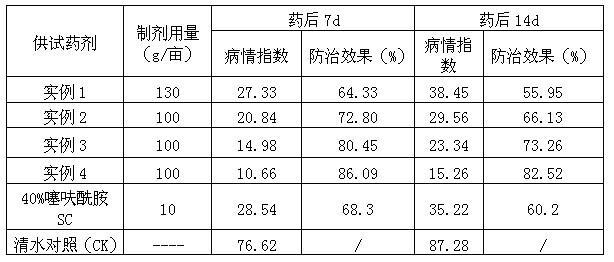

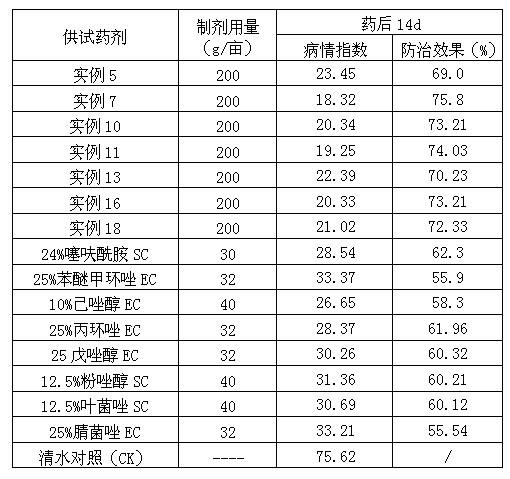

Examples

example 1

[0039] Example 1 0.5% Thiofuramide Ultra-low Volume Liquid

[0040] Thiofuramide 0.5kg

[0041] Nonylphenol ethoxylate 1kg

[0042] N,N-Dimethylformamide 5kg

[0043] Methyl oleate 10kg

[0044] Second line oil make up to 100kg

[0045] Preparation process: Weigh each component according to the weight percentage of each component. Under normal temperature and pressure, in a reaction vessel, first stir the active ingredient with a solvent until it is completely dissolved. The stirring speed is controlled at 60 rpm, and then add Auxiliary ingredients, continue to stir for 60 minutes, mix evenly, and you are ready.

example 2

[0046] Example 2 3% Thiofuramide Ultra-Low Volume Liquid

[0047] Thiofuramide 3kg

[0048] Calcium alkylbenzene sulfonate 3.5kg

[0049] Alkylphenol polyoxyethylene ether 1.5kg

[0050] Sulfolane 10kg

[0051] Methyl oleate 10kg

[0052] Diesel to make up to 100kg

[0053] Preparation process: Weigh each component according to the weight percentage of each component. Under normal temperature and pressure, in the reaction vessel, first use a solvent to stir and dissolve the active ingredient. The stirring speed is controlled at 80 rpm, and then add the auxiliary agent Ingredients, continue to stir for 15 minutes, mix well, that is.

[0054]

example 3

[0055] Example 3 5% Thiofuramide Ultra-low Volume Liquid

[0056] Thiofuramide 5kg

[0057] Calcium alkylbenzene sulfonate 3.5kg

[0058] Nonylphenol ethoxylate 1.5kg

[0059] Dimethyl sulfoxide 15kg

[0060] n-octanol 10kg

[0061] Soybean oil make up to 100kg

[0062] Preparation process: Weigh each component according to its weight percentage. Under normal temperature and pressure, in a reaction vessel, first use a solvent to stir and dissolve the active ingredient. The stirring speed is controlled at 150 rpm, and then add additives Ingredients, continue to stir for 30 minutes, mix well, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com