Dispersion type liquid mildew inhibitor and preparation method thereof

A kind of antifungal agent and diffusion type technology, which is applied in food science, food preservation, animal feed, etc., to achieve the effect of less dosage, high economic and social benefits, and long antifungal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

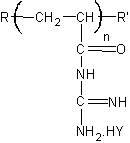

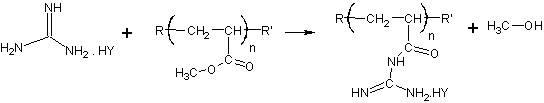

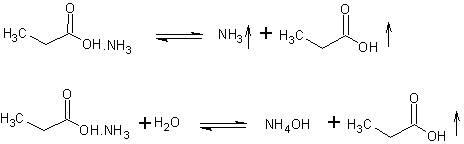

Method used

Image

Examples

Embodiment 1

[0057] Diffusion type liquid antifungal agent, which is composed of the following ingredients in mass percentage:

[0058] Propionic Acid 40%, Ammonium Propionate 30%, Guanidine Polymer 30%.

Embodiment 2

[0060] Diffusion type liquid antifungal agent, which is composed of the following ingredients in mass percentage:

[0061] Propionic Acid 30%, Ammonium Propionate 40%, Guanidine Polymer 30%.

Embodiment 3

[0063] Diffusion type liquid antifungal agent, which is composed of the following ingredients in mass percentage:

[0064] Propionic Acid 40%, Ammonium Propionate 40%, Guanidine Polymer 20%.

[0065]

[0066] Effect verification:

[0067] Randomly select 200 kilograms of wheat with a water content of 11.85%, and the spraying amount of the antimold agent and solid antimold agent (Basf, Germany, Lubao Fine Salt) of Embodiment 1-3 is 200 grams, and the environmental conditions are 40°C of temperature and 90°C of humidity. %, to observe the anti-mildew effect, the results are shown in the following table:

[0068] 20 days 40 days 60 days 80 days 100 days 120 days no fungicide no mildew no mildew Start to mildew Moderate mildew most mildew All mildew Solid antifungal agent no mildew no mildew no mildew Start to mildew Moderate mildew most mildew The diffusion type liquid antifungal agent of embodiment 1 no mildew no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com