Method for extracting crystal from magma

A crystal slurry and crystal technology, which is applied in the direction of solution crystallization, feeding/discharging device of settling tank, settling tank, etc., can solve the problems of low bulk density, difficult to dry, high water content, etc. Excellent agglomeration performance and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

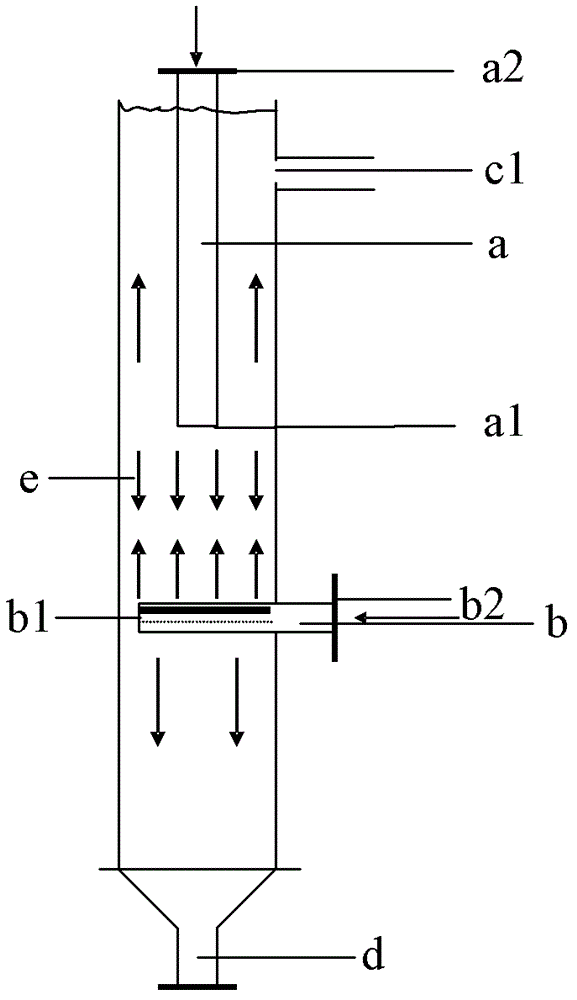

[0055] This embodiment is used to illustrate the utilization of the present invention figure 2 The shown crystal slurry liquid elutriation device extracts the method for crystal from the citric acid crystal slurry.

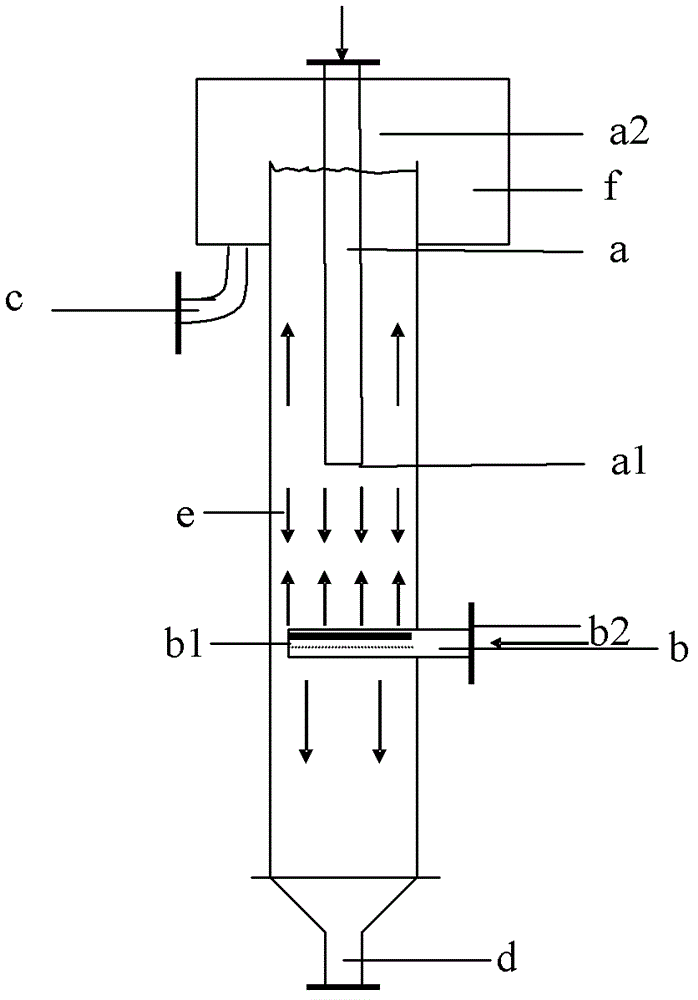

[0056] The crystal slurry elutriation device comprises an elutriator tank e with an open top, a crystal slurry feed pipe a, an elutriation liquid feed pipe b and a sump f connected to the top of the elutriator tank e, so The bottom of the elutriator tank e is provided with a crystal outlet d, and one end a1 of the crystal slurry feed pipe a extends into the inside of the elutriator tank e from the top of the elutriator tank e, and the other end a2 The port of the elutriator tank body e is higher than the top port of the elutriator tank body e, and one end b1 of the elutriation liquid feed pipe b extends into the inside of the elutriator tank body e from the side wall of the elutriator tank body e, and the other end b2 The port of is located outside the elutriato...

Embodiment 2

[0060] This embodiment is used to illustrate the utilization of the present invention figure 2 The shown crystal slurry liquid elutriation device extracts the method for crystal from the citric acid crystal slurry.

[0061] Extract citric acid crystals from the citric acid crystal slurry according to the method of embodiment 1, the difference is that the length of the crystal slurry feed pipe a stretching into the elutriator tank e is 560mm, and the length of one end a1 of the crystal slurry liquid feed pipe a The minimum distance from the port to the elutriation solution feed pipe b is 1120mm; the elutriation solution used is deionized water; the flow rates of the citric acid crystal slurry and the elutriation solution are 11m 3 / h and 1m 3 / h.

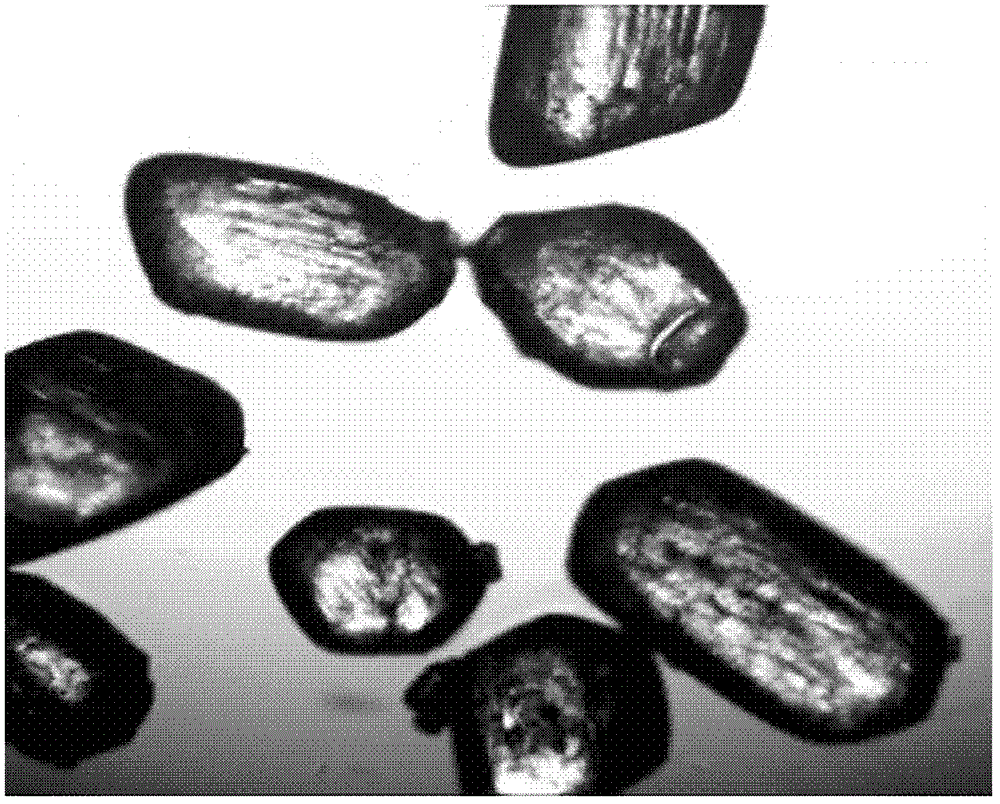

[0062] The solid obtained by centrifugal separation (the water content is 0.82% by weight) is dried to obtain anhydrous citric acid crystal product. The content of anhydrous citric acid crystals in the obtained anhydrous citric a...

Embodiment 3

[0064] This embodiment is used to illustrate the utilization of the present invention figure 2 The shown crystal slurry liquid elutriation device extracts the method for crystal from the citric acid crystal slurry.

[0065] Extract citric acid crystals from the citric acid crystal slurry according to the method of Example 1, the difference is that the crystal slurry feed pipe a stretches into the elutriator tank e and is the port of one end a1 of the 1400mm crystal slurry feed pipe a in length The minimum distance to the elutriation solution feed pipe b is 560mm; the elutriation solution used is the feed liquid before concentrated crystallization in the citric acid extraction process, and the saturation is 100%; the flow rates of the citric acid crystal slurry and the elutriation solution are 7m 3 / h and 1m 3 / h.

[0066] The solid obtained by centrifugal separation (the water content is 0.86% by weight) is dried to obtain anhydrous citric acid crystal product. The content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com