Cypress defatting method

A technology of cypress and cypress oil, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problem of not being able to degrease in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention relates to a method for degreasing cypress wood. In the method, the log is first processed into a board with a certain thickness according to requirements, and then the wood is placed in a closed container, and the cypress board is heated by steam, and steaming is performed with saturated steam at the same time. The resin contained in the cypress is liquefied, the resin is dissolved into cedar oil, and the cedar oil is heated and azeotroped with water vapor, and the cedar oil in the cedar board is continuously volatilized, and the wood is discharged together with the migration of water and water vapor, thereby exuding the resin. To achieve the purpose of degreasing.

[0035] In the present invention, the drying kiln adopted is the top fan drying kiln commonly used in the prior art, and is made up of following system:

[0036] (1) Kiln door and kiln door opening and closing device;

[0037] (2) Electrical control system: electrical control cabinet, solenoi...

Embodiment 2

[0042] As a best implementation mode of the present invention is:

[0043] Step 1: Process the cypress log into a plate with a thickness of 25mm as required.

[0044] Step 2: Put the cypress boards with a thickness of 25mm into the drying kiln and close the kiln door.

[0045] Step 3: Raise the temperature in the drying kiln to 50-55°C first, and then spray saturated steam to the drying kiln to make the dry and wet bulb temperatures of the medium in the drying kiln both reach 78-80°C, and steam and degrease the board , steam degreasing time is 3h.

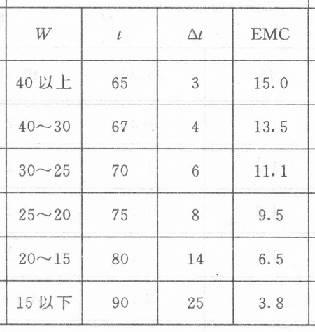

[0046] Step 4: After steaming, transfer the cypress board to the normal drying process according to the kiln drying benchmark table. During the whole drying process, steaming and heating must be carried out in strict accordance with the requirements of the drying standard to further degrease the cypress board. When the wood moisture content reaches 8-10%, the drying ends and the final balance treatment is carried out.

[0047] ...

Embodiment 3

[0053] As a preferred embodiment of the present invention is:

[0054] Step 1: Process the cypress log into a plate with a thickness of 40 mm as required.

[0055] Step 2: Put the 40mm thick cypress board into the drying kiln and close the kiln door.

[0056] Step 3: Raise the temperature in the drying kiln to 55-60°C first, and then spray saturated steam to the drying kiln to make the dry and wet bulb temperatures of the medium in the drying kiln both reach 82-85°C, and steam and degrease the board , steam degreasing time is 4h.

[0057] Step 4: After steaming, transfer the cypress board to the normal drying process according to the kiln drying benchmark table. During the whole drying process, steaming and heating must be carried out in strict accordance with the requirements of the drying standard to further degrease the cypress board. When the wood moisture content reaches 8-10%, the drying ends and the final balance treatment is carried out.

[0058] Step 5: After degrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com