Method for preparing adhesive coating and adhesive film based on layer-by-layer assembly technology

A layer-by-layer assembly, bonding coating technology, applied in the direction of film/sheet adhesives, adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

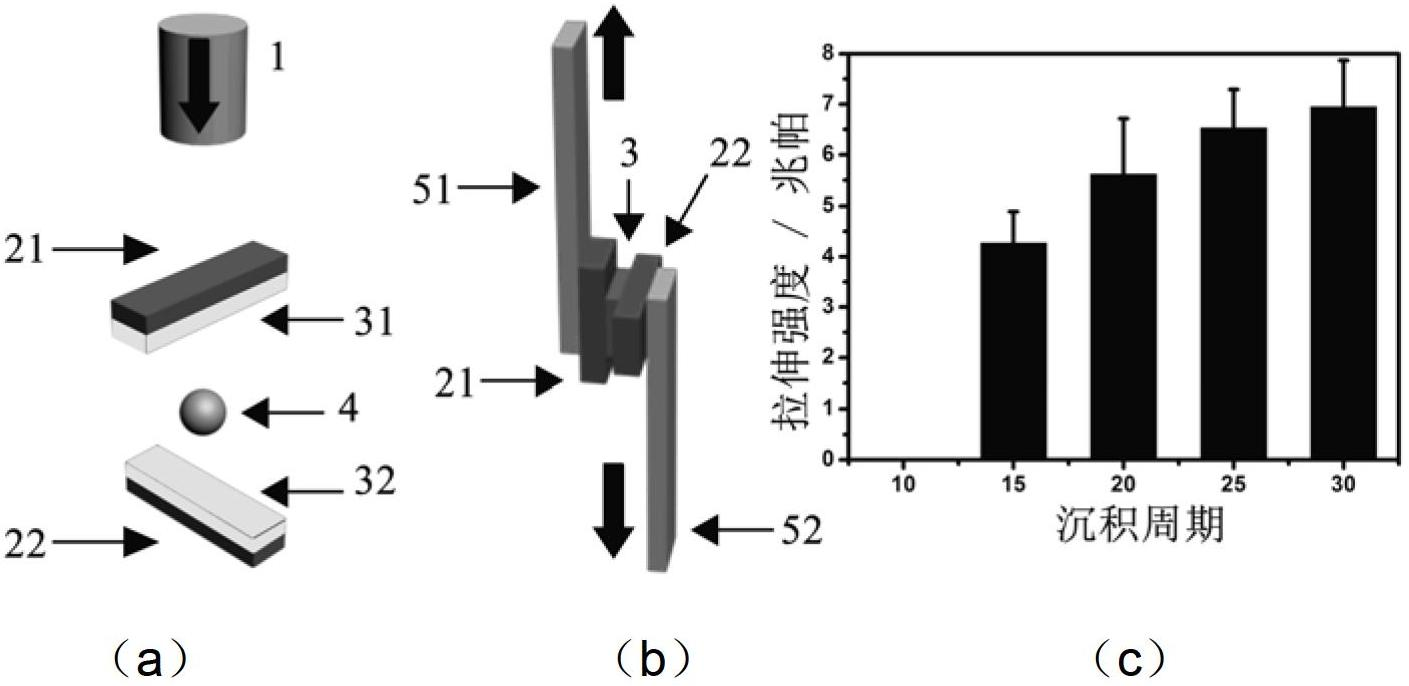

[0037] Example 1: Preparation and Adhesive Application of Adhesive Coatings on Glass Surfaces.

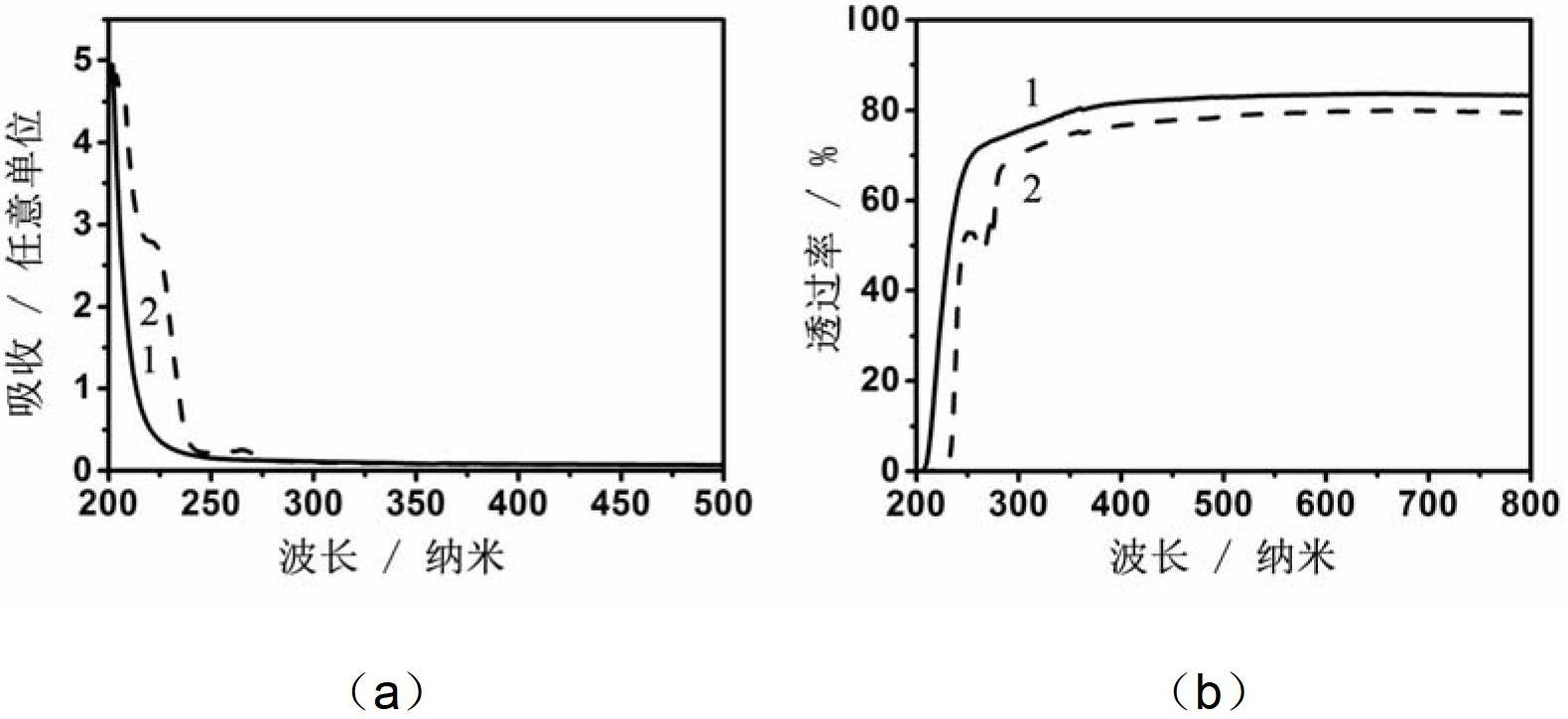

[0038] The glass substrate was alternately immersed in PAH-D (1mg / mL, pH=7.4) and HA solution (1mg / mL, pH=7.4) for 15 minutes each, and this step was repeated to obtain an adhesive coating. After each step of immersion, the substrate is washed with water and dried with nitrogen. figure 1 The process of film thickness changing with the number of deposition cycles was tracked and monitored by surface profiler. It shows that the adhesion coating grows in a typical exponential growth form, that is, the thickness of the adhesion coating increases rapidly as the number of deposition cycles increases.

[0039] In this example, the concentrations of PAH-D and HA solutions are both 1 mg / mL, and the pH values are both physiological pH values, that is, 7.4. Changing the concentration of the solution will not have a significant impact on the construction of the membrane, but if the concent...

Embodiment 2

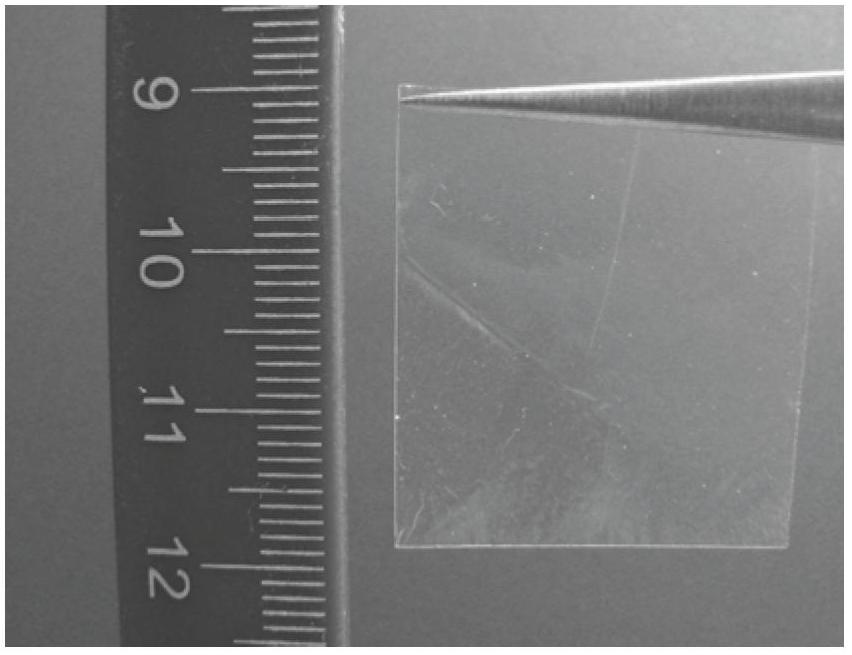

[0041] Example 2: Preparation and Adhesive Application of Adhesive Film

[0042] (PAH-D / HA)*30 membrane has very good guest molecule loading capacity. We firstly spin-coated 20 mg / mL cellulose acetate acetone solution on the glass surface at 3000 rpm to obtain ~1.5 micron cellulose acetate sacrificial layer on the glass surface. After cleaning in the plasma cleaning agent for 3 minutes, build a 30-period adhesive coating of PAH-D / HA on the surface of the cellulose acetate sacrificial layer (its concentration and pH value are as in Example 1), and soak it as a whole in 15mM pH = 7.4 ibuprofen solution for 3 hours; followed by immersing the whole in acetone for 3 minutes, so that the layer-by-layer assembled polyelectrolyte adhesive coating and the glass sheet were separated by the dissolution of cellulose acetate, thus obtaining a self-supporting Adhesive film. And transfer the self-supporting layer-by-layer assembly membrane to another container with acetone for rinsing for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com